910716

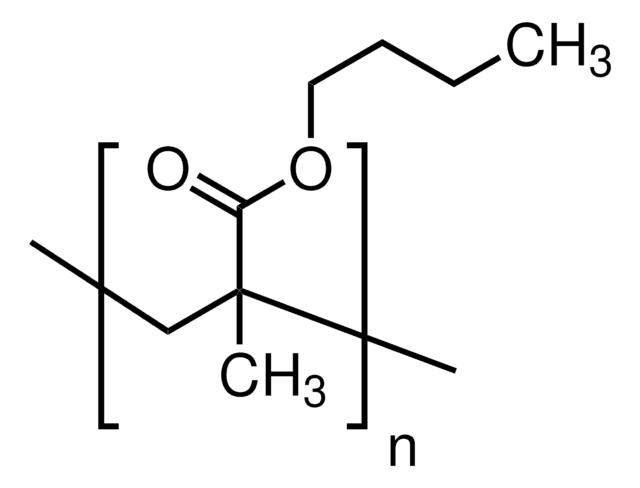

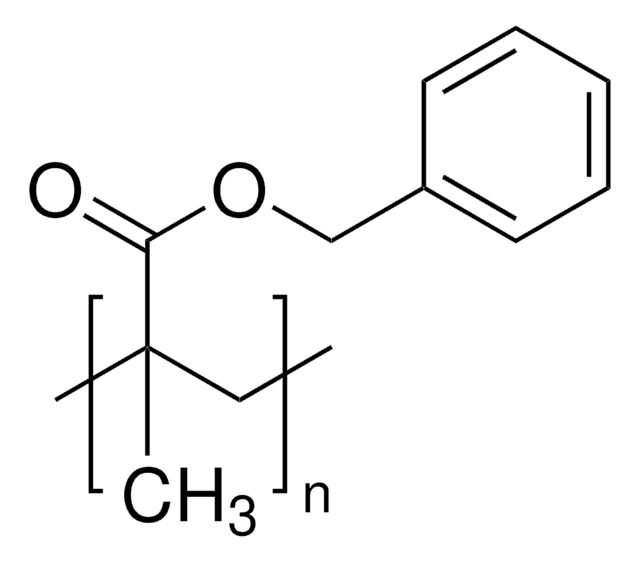

Poly(butyl methacrylate)

free flow beads, Mw 211,000

Sinônimo(s):

PBMA

About This Item

Produtos recomendados

descrição

Brookfield Viscosity in 40% toluene: 500-800 cPs

Glass transition temperature onset: 20 °C

Maximum % Moisture: 0.30%

Formulário

solid (bead)

peso molecular

Mw 211,000

índice de refração

n/D 1.483

densidade

1.07 g/mL at 25 °C (lit.)

cadeia de caracteres SMILES

O(CCCC)C(=O)C(=C)C

InChI

1S/C8H14O2/c1-4-5-6-10-8(9)7(2)3/h2,4-6H2,1,3H3

chave InChI

SOGAXMICEFXMKE-UHFFFAOYSA-N

Descrição geral

Conventional high molecular weight poly(butyl methacrylate) easily forms a fused block that require mechanical force (such as hammering) to break it down into small particles before usage. This product was developed with an anti-blocking technology and comes in an easy-to-use, free flowing, bead form.

Aplicação

It may be used to study the photoluminescence in EuTFC embedded in Poly(butyl methacrylate) (PBMA) polymer films.

It has also been used for coatings, surface modification, solid state battery, silk screen inks, adhesives for plastic and aluminum, plasticizer for hard butyl methacrylate resins, and for improving outdoor durability of vinyl chloride resins in pigmented lacquers.

Nota de preparo

This polymer dissolves at room temperature but requires constant agitation to prevent solvent-swollen granules of polymer from forming agglomerates and sticking to the walls of the vessel.

Important: The polymer beads should be sifted directly into the vortex of the stirred solvent to speed wetting-out and dispersion. Continuous low-shear agitation for periods of 1-12 hours, depending on the grade and concentration of resin, is recommended.

After the solution appears clear in the tank, a sample should be spread out on a Leneta card or glass. After the solvent evaporates and a film forms on the card or glass, there should not be any resin seeds. If there are any seeds, the tank should be agitated further to fully dissolve the resin. Tank agitation should not be stopped (except for sampling) until the film test indicates there are no resin seeds. Any cloudiness or residue may indicate that some polymer remains undissolved. The presence of water in the system can also cause cloudiness.

Solution time can be reduced by heating; most common solvents can be heated to approximately 49°C (120°F) without the need for reflux equipment. High-shear agitation also cuts dissolving time, but requires care to avoid overheating and excessive solvent loss.

Palavra indicadora

Warning

Frases de perigo

Declarações de precaução

Classificações de perigo

Skin Sens. 1

Código de classe de armazenamento

11 - Combustible Solids

Classe de risco de água (WGK)

WGK 3

Ponto de fulgor (°F)

Not applicable

Ponto de fulgor (°C)

Not applicable

Escolha uma das versões mais recentes:

Certificados de análise (COA)

Não está vendo a versão correta?

Se precisar de uma versão específica, você pode procurar um certificado específico pelo número do lote ou da remessa.

Já possui este produto?

Encontre a documentação dos produtos que você adquiriu recentemente na biblioteca de documentos.

Artigos

Synthesis and Applications of Graphene Nanoribbons Synthesized

Nossa equipe de cientistas tem experiência em todas as áreas de pesquisa, incluindo Life Sciences, ciência de materiais, síntese química, cromatografia, química analítica e muitas outras.

Entre em contato com a assistência técnica