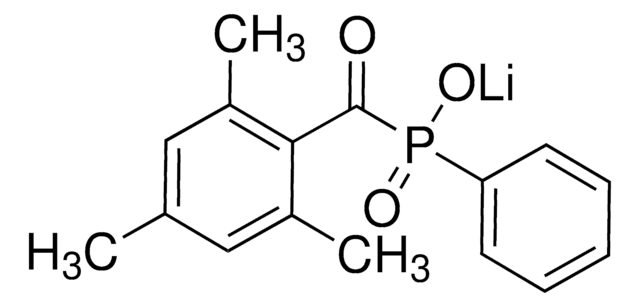

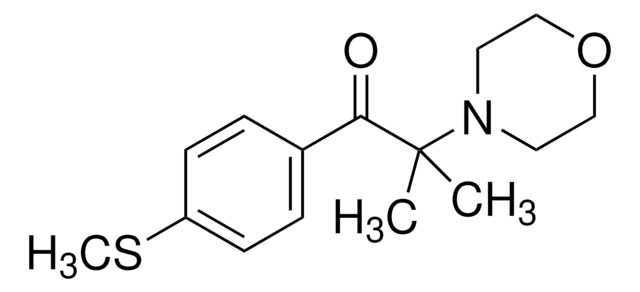

415952

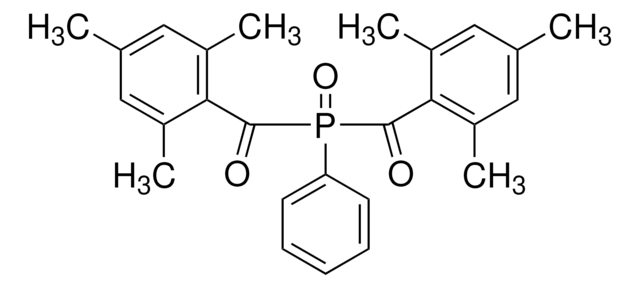

Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide

97%

Sinônimo(s):

(2,4,6-Trimethylbenzoyl)diphenylphosphine oxide, (Diphenylphosphoryl)(mesityl)methanone, 2,4,6-Trimethylbenzoylphenyl phosphinate

About This Item

Produtos recomendados

Ensaio

97%

Formulário

powder

pf

88-92 °C (lit.)

cadeia de caracteres SMILES

Cc1cc(C)c(c(C)c1)C(=O)P(=O)(c2ccccc2)c3ccccc3

InChI

1S/C22H21O2P/c1-16-14-17(2)21(18(3)15-16)22(23)25(24,19-10-6-4-7-11-19)20-12-8-5-9-13-20/h4-15H,1-3H3

chave InChI

VFHVQBAGLAREND-UHFFFAOYSA-N

Descrição geral

Aplicação

Armazenamento e estabilidade

Palavra indicadora

Warning

Frases de perigo

Declarações de precaução

Classificações de perigo

Aquatic Chronic 2 - Repr. 2 - Skin Sens. 1

Código de classe de armazenamento

11 - Combustible Solids

Classe de risco de água (WGK)

WGK 2

Ponto de fulgor (°F)

Not applicable

Ponto de fulgor (°C)

Not applicable

Equipamento de proteção individual

Eyeshields, Gloves, type N95 (US)

Escolha uma das versões mais recentes:

Já possui este produto?

Encontre a documentação dos produtos que você adquiriu recentemente na biblioteca de documentos.

Os clientes também visualizaram

Artigos

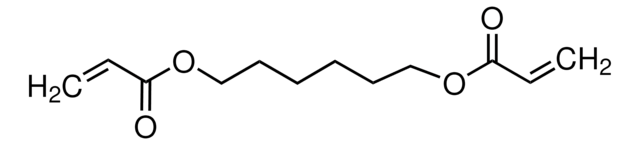

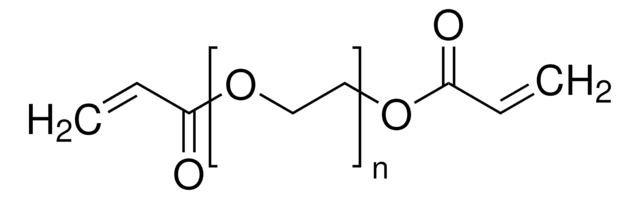

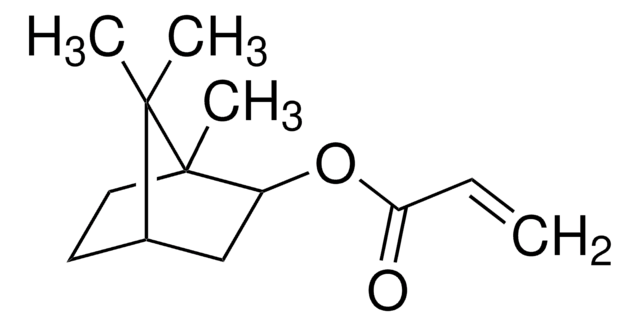

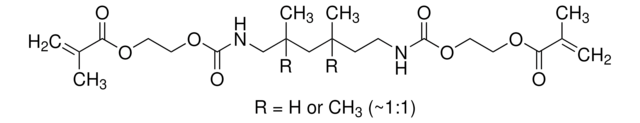

The manufacture of monomers for use in ophthalmic applications is driven by the need for higher purity, improved reliability of manufacturing supply, but ultimately by the need for the increased comfort, convenience, and safety of contact lens wearers. Daily wear contact lenses have the potential to fill this need for many customers; however, their widespread use is constrained by higher costs compared to weekly- or monthly-based lenses. New approaches that improve cost structure and result in higher quality raw materials are needed to help make contact lenses more affordable and accelerate growth of the contact lens market.

Nossa equipe de cientistas tem experiência em todas as áreas de pesquisa, incluindo Life Sciences, ciência de materiais, síntese química, cromatografia, química analítica e muitas outras.

Entre em contato com a assistência técnica