901773

Silver/silver chloride (60/40) paste for screen printing

Synonim(y):

Ag/AgCl paste, C2130809D5, conductive ink

About This Item

Polecane produkty

opis

Coverage: 200 cm2 per g (using a 156 mesh polyester screen)

Sheet resistivity:<100 miliohms per square (20 micron thick printed on alumina substrate)

Postać

paste

lepkość

2.0-5.5 Pa.s (Haake RS1 C20/2° TiL at 230 sec-1 at 25°C)

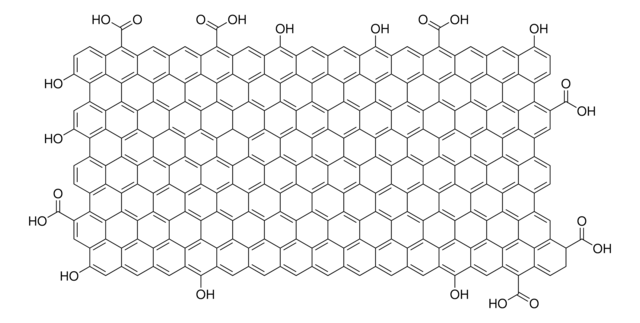

Opis ogólny

Zastosowanie

- Highly sensitive determination of heavy metals in water prior to and after remediation using Citrofortunella Microcarpa: This study utilizes Silver-silver chloride (Ag/AgCl) Paste (60:40) in screen printing electrodes for environmental monitoring applications (Palisoc et al., 2021).

- Screen-printed graphite electrodes as low-cost devices for oxygen gas detection in room-temperature ionic liquids: This research incorporates a silver/silver chloride reference electrode by screen-printing Ag/AgCl paste (60:40) onto a flexible film, exploring its effectiveness in gas sensing technologies (Lee et al., 2017).

- Simple Portable Voltammetric Sensor Using Anodized Screen-Printed Graphene Electrode for the Quantitative Analysis of p-Hydroxybenzoic Acid in Cosmetics: In this study, silver/silver chloride paste (Ag/AgCl: 60/40) was used to enhance the functionality of screen-printed electrodes for cosmetic analysis (Charoenkitamorn et al., 2022).

- Dipstick Sensor Based on Molecularly Imprinted Polymer-Coated Screen-Printed Electrodes for Single-Shot Detection of Glucose in Urine Samples: This research features the use of silver/silver chloride (60:40) reference electrode, screen-printed onto plastic for biomedical applications (Caldara et al., 2023).

- Simultaneous determination of ascorbic acid, dopamine, and uric acid using graphene quantum dots/ionic liquid modified screen-printed carbon electrode: Utilizes carbon ink and silver/silver chloride (Ag/AgCl) paste 60/40 for developing advanced sensor platforms (Kunpatee et al., 2020).

Cechy i korzyści

- Applications in medical diagnostics, environmental sensors

- High conductivity

- Low curing temperature

Uwaga dotycząca przygotowania

- Screen Printing Equipment: semi-automatic, manual

- Ink Screen Life: >3 hours

- Screen Types: polyester, mesh 156 to 230 tpi

Note: Stainless Steel mesh is not recommended, since a paste component can become corrosive in the presence of moisture.Also, plastic palette knives should be used instead of metal knives.

- Typical Drying Conditions: Dry at 60°C for 30minutes or 80°C for 10minutes in a box oven.

- Clean up solvent: ethoxyl propanol or seriocol

- Substrate: polyester, PVC, polycarbonate and alumina

Informacje prawne

Hasło ostrzegawcze

Warning

Zwroty wskazujące rodzaj zagrożenia

Zwroty wskazujące środki ostrożności

Klasyfikacja zagrożeń

Aquatic Acute 1 - Aquatic Chronic 1 - Met. Corr. 1

Kod klasy składowania

8A - Combustible corrosive hazardous materials

Klasa zagrożenia wodnego (WGK)

WGK 3

Temperatura zapłonu (°F)

192.2 °F

Temperatura zapłonu (°C)

89 °C

Wybierz jedną z najnowszych wersji:

Masz już ten produkt?

Dokumenty związane z niedawno zakupionymi produktami zostały zamieszczone w Bibliotece dokumentów.

Klienci oglądali również te produkty

Produkty

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Nasz zespół naukowców ma doświadczenie we wszystkich obszarach badań, w tym w naukach przyrodniczych, materiałoznawstwie, syntezie chemicznej, chromatografii, analityce i wielu innych dziedzinach.

Skontaktuj się z zespołem ds. pomocy technicznej