347078

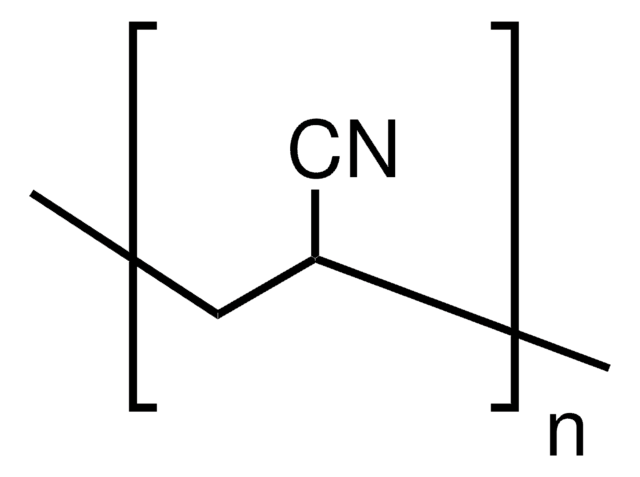

Poly(vinylidene fluoride)

average Mw ~530,000, pellets

Sinônimo(s):

PVDF

Faça loginpara ver os preços organizacionais e de contrato

About This Item

Fórmula linear:

(CH2CF2)n

Número CAS:

Número MDL:

Código UNSPSC:

12162002

ID de substância PubChem:

NACRES:

NA.23

Produtos recomendados

pressão de vapor

15 mmHg ( 32 °C)

Nível de qualidade

forma

pellets

peso molecular

average Mw ~530,000

cadeia de caracteres SMILES

FC(F)=C

InChI

1S/C2H2F2/c1-2(3)4/h1H2

chave InChI

BQCIDUSAKPWEOX-UHFFFAOYSA-N

Procurando produtos similares? Visita Guia de comparação de produtos

Categorias relacionadas

Aplicação

- A critical analysis of the α, β and γ phases in poly (vinylidene fluoride) using FTIR: This study provides detailed insights into the different crystalline phases of PVDF, which are crucial for applications in sensors and actuators (Cai et al., 2017).

- Properties and applications of the β phase poly (vinylidene fluoride): This research explores the unique properties of the β phase of PVDF, widely used for its piezoelectric and ferroelectric properties, relevant in various technological applications (Ruan et al., 2018).

- Ultrahigh β-phase content poly (vinylidene fluoride) with relaxor-like ferroelectricity for high energy density capacitors: This article discusses the potential of high β-phase PVDF in energy storage applications, which could interest material scientists focusing on energy solutions (Meng et al., 2019).

- Multiscale-structuring of polyvinylidene fluoride for energy harvesting: This study investigates how different scales of structural modification affect the energy harvesting capabilities of PVDF, important for both material science and sustainable energy research (Wan & Bowen, 2017).

- Recent advances in poly (vinylidene fluoride) and its copolymers for lithium-ion battery separators: This review highlights the applications of PVDF in the development of lithium-ion battery separators, essential for advancing energy storage technologies (Barbosa et al., 2018).

Código de classe de armazenamento

11 - Combustible Solids

Classe de risco de água (WGK)

WGK 3

Ponto de fulgor (°F)

Not applicable

Ponto de fulgor (°C)

Not applicable

Equipamento de proteção individual

Eyeshields, Gloves, type N95 (US)

Escolha uma das versões mais recentes:

Já possui este produto?

Encontre a documentação dos produtos que você adquiriu recentemente na biblioteca de documentos.

Os clientes também visualizaram

Yu-Jen Hsu et al.

The Journal of the Acoustical Society of America, 132(6), 3826-3831 (2012-12-13)

A tone analyzer is demonstrated using a distributed resonator architecture on a tensioned piezoelectric polyvinyledene diuoride (PVDF) sheet. This sheet is used as both the resonator and detection element. Two architectures are demonstrated; one uses distributed, directly addressed elements as

S V Ivanov et al.

Klinichna khirurhiia, (7)(7), 37-41 (2012-10-05)

The results of experimental and clinical studies for the comparative evaluation of implants used in herniology of polytetrafluoroethylene (PTFE) and polyvinylidene fluoride (PVDF) are presented. Experimental investigations conducted on 200 mice, which in the anterior abdominal wall mesh prosthesis implanted.

X S Yi et al.

Water science and technology : a journal of the International Association on Water Pollution Research, 67(3), 477-484 (2012-12-04)

In the present study, nano-sized TiO(2)/Al(2)O(3) modified polyvinylidene fluoride (PVDF) membranes (MM) were fabricated and then utilized for oil/water emulsion separation. The results showed that, compared with PVDF membrane (OM), the contact angle of MM decreased and hydrophilicity increased. The

Adhikara Resosudarmo et al.

Water research, 47(2), 911-921 (2012-12-12)

Organic fouling remains a significant challenge in the application of ultrafiltration (UF) pretreatment systems in the desalination industry. In this study, the fouling potential of organic materials in seawater was investigated using model seawater solution containing humic acid and alginate.

Vincent S D Voet et al.

Nanoscale, 5(1), 184-192 (2012-11-10)

The fabrication of nanoporous poly(vinylidene fluoride) (PVDF) and PVDF/nickel nanocomposites from semicrystalline block copolymer precursors is reported. Polystyrene-block-poly(vinylidene fluoride)-block-polystyrene (PS-b-PVDF-b-PS) is prepared through functional benzoyl peroxide initiated polymerization of VDF, followed by atom transfer radical polymerization (ATRP) of styrene. The

Nossa equipe de cientistas tem experiência em todas as áreas de pesquisa, incluindo Life Sciences, ciência de materiais, síntese química, cromatografia, química analítica e muitas outras.

Entre em contato com a assistência técnica