916579

3D Printable Graphene Oxide Ink

avg. no. of layers, 1

Synonym(s):

3D Printing graphene oxide ink, Direct extrusion printable graphene oxide ink

About This Item

Recommended Products

description

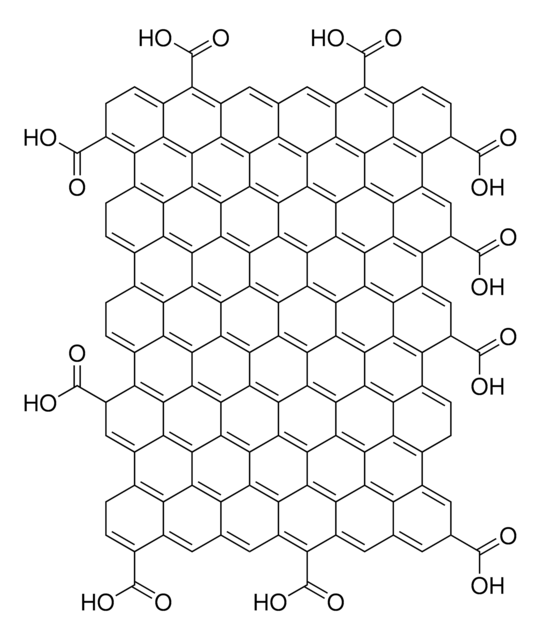

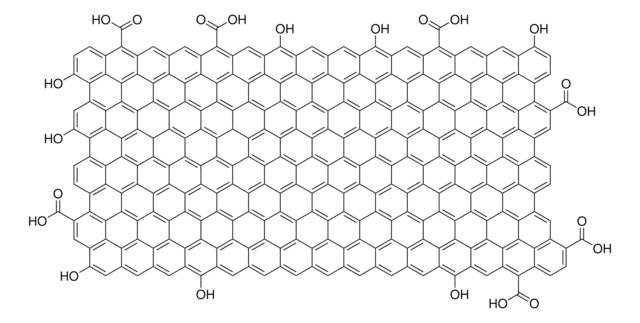

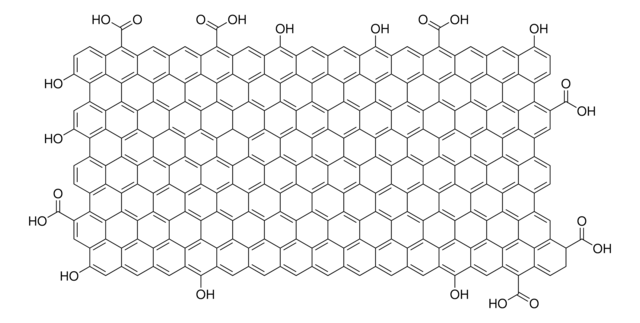

Graphene oxide sheet size: 300-800 nm lateral size

Number of layer for graphene oxide: single layer

Quality Level

form

liquid

feature

avg. no. of layers 1

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

concentration

40 mg/mL (Graphene oxide aquous ink)

viscosity

100-210 Pa.s (25 °C at shear rate of 10 s-1)

greener alternative category

, Enabling

storage temp.

2-8°C

Related Categories

General description

Application

Preparation Note

Bring the ink to room temeprature, best to mix the ink in a planetary mixer before usage.

Printing:

Recommended 3D printing nozzle diameter size is 400 micron.

Post printing:

After 3D printing, this ink can be directly freeze-dried in liquid nitrogen and vacuum to obtain free- standing graphene oxide aerogel.

This ink can also be processed by adding gelling agents to enable a covalent bond established between the graphene oxide sheets. Gelation agents such as ammonium carbonate, ammonium hydroxide, resorcinol formaldehyde have all been reported to be sufficient. After gelation, the wet GO gels printed parts are washed in acetone to remove water from the pores. Supercritical CO2 can then be used to dry the GO gels.

Curing:

Parts that are printed with gelling agent can be cured in sealed glass vials at 85 °C.

The dried aerogels are generally reduced to graphene aerogels by thermal treatment at 1050 °C under inert atmosphere. Other chemical reduction methods include hydrazine reduction, dried aerogels can also be reduced using hydroiodic acid, followed by washing in ethanol, water and then freeze drying.

Storage and Stability

Storage Class

10 - Combustible liquids

wgk_germany

WGK 3

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Partnering additive manufacturing (3D printing) with functional nanomaterial-based inks has the potential to push the properties and performance of advanced materials beyond previous capabilities. This is particularly true in energy and environmental applications.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service