191884

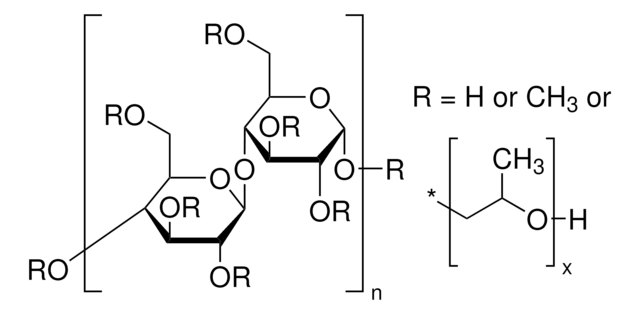

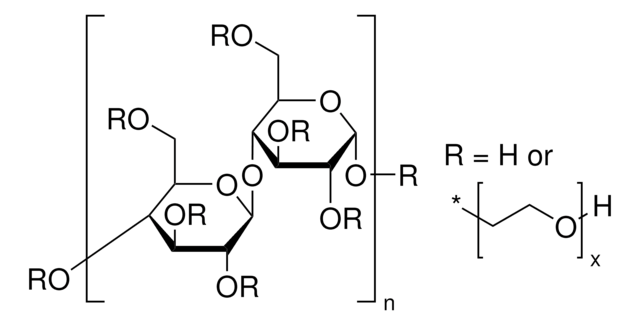

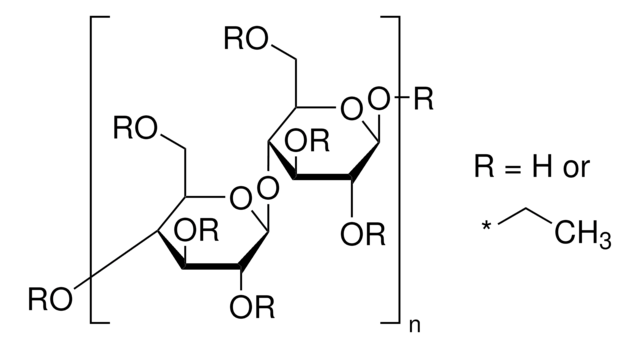

Hydroxypropyl cellulose

average Mw ~100,000, powder, 20 mesh particle size (99% through)

About This Item

Recommended Products

description

biological oxygen demand (BOD) 14,000 ppm

Quality Level

form

powder

autoignition temp.

752 °F

mol wt

average Mw ~100,000

impurities

<5 wt. %

particle size

20 mesh (99% through)

pH

5.0-8.5

interfacial tension mineral oil

12.5 dyn/cm, 0.1 wt. % in H2O (vs. mineral oil)

viscosity

65-175 cP, 5 wt. % in H2O(25 °C, Brookfield, spindle #1) (30 rpm)(lit.)

solubility

polar organic solvents: soluble

density

0.5 g/mL at 25 °C (lit.)

InChI

1S/C12H20N2/c1-5-12(13)11-7-6-10(14(3)4)8-9(11)2/h6-8,12H,5,13H2,1-4H3

InChI key

RRHXDYJWVYFMKV-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Application

- HPC is soluble in organic solvents which makes it suitable for the preparation of polymer gel electrolytes for electrochemical devices. The network-forming ability of HPC can improve the mechanical and electrical properties of gel electrolytes.

- Electrospun hydroxypropyl cellulose nanofibres can be used to develop drug delivery systems for a variety of hydrophobic drugs.

- Hydroxypropylcellulose combined with an effervescent agent like sodium carbonate can be usedas a binder and functional material to prepare floating tablets for thecontrolled release of ofloxacin.

Storage Class

11 - Combustible Solids

wgk_germany

WGK 1

flash_point_f

Not applicable

flash_point_c

Not applicable

ppe

Eyeshields, Gloves, type N95 (US)

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service