おすすめの製品

環境により配慮した代替製品の特徴

Design for Energy Efficiency

Use of Renewable Feedstocks

Learn more about the Principles of Green Chemistry.

品質水準

sustainability

Greener Alternative Product

環境により配慮した代替製品カテゴリ

詳細

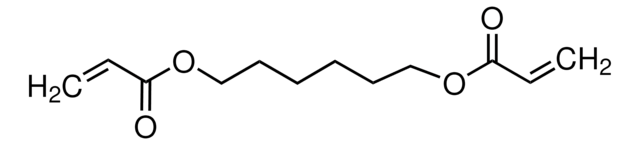

We are committed to bringing you Greener Alternative Products, which adhere to one or more of The 12 Principles of Greener Chemistry. This product belongs to enabling category of greener alternatives and it is bio-degradable and thus aligns with "Design for energy efficiency" and "Use of renewable feedstocks".UV curable resins are bio-based products which are solidified through a chain polymerisation reaction by uv rays. It shows excellent thermal and mechanical properties. Click here for more information.

アプリケーション

The Ultracur3D® photopolymer works with following technologies: Stereolithography (SLA), Digital Light Processing (DLP) and Liquid Crystal Display (LCD).

SLA can be used to create highly complex prototypes with a smooth surface finish. It offers high surface finishing and accuracy, while perfect for printing very large parts.

DLP is your go-to method when opting for a quick printing process without compromising on the quality of intricate parts. It provides high productivity, and can be used for larger and smaller parts.

LCD provides the opportunity to replace low and medium series injection molds with large parts. One of the biggest benefits of printing with Liquid Crystal Display (LCD) is to enable economic and large-scale production.

SLA can be used to create highly complex prototypes with a smooth surface finish. It offers high surface finishing and accuracy, while perfect for printing very large parts.

DLP is your go-to method when opting for a quick printing process without compromising on the quality of intricate parts. It provides high productivity, and can be used for larger and smaller parts.

LCD provides the opportunity to replace low and medium series injection molds with large parts. One of the biggest benefits of printing with Liquid Crystal Display (LCD) is to enable economic and large-scale production.

This product can be used in Material Jetting or Vat polymerization 3D printing techniques.

Ultracur3D® RG 35 N and Ultracur3D® RG 35 can be sterilized through Steam or EtO methods, but the color and mechanical property changes need to be taken into consideration by the user. When exposed to E-Beam sterilization, Ultracur3D® RG 35 demonstrates a 17% increase in elongation at break and 37% increase in E-modulus. The samples also show an 18% increase in ultimate strength. The specimens show some reddish color post-sterilization.

When exposed to EtO sterilization, Ultracur3D® RG 35 or RG35N demonstrates a 12 % increase in elongation at break and 15 % increase in modulus. The samples also show a 14 % increase in ultimate strength. The test specimens show a small color change but become lighter and more clear post-sterilization. EtO residuals level after exposure were not recorded.

Testing conditions Ethylene Oxide Sterilization:

When exposed to EtO sterilization, Ultracur3D® RG 35 or RG35N demonstrates a 12 % increase in elongation at break and 15 % increase in modulus. The samples also show a 14 % increase in ultimate strength. The test specimens show a small color change but become lighter and more clear post-sterilization. EtO residuals level after exposure were not recorded.

Testing conditions Ethylene Oxide Sterilization:

- Preconditioning temperature 48 °C

- Preconditioning humidity 60%

- Preconditioning time 8 hours

- Chamber temperature 45 °C

- Vacuum 75 mbar A

- EO dwell time 3 hours

- EO concentration (calculated) 610 mg/l

- Postconditioning time 48 hours

- Postconditioning temperature 45 °C

Ultracur3D® RG 35 N is a white UV curable resin that, upon cure, produces rigid plastic material of opaque off white natural color. This photocurable resin is suitable for DLP and SLA 3D printing using 355 nm, 385 nm or 405 nm light source for a variety of industrial and biomedical/dental applications requiring mechanical strength.

The product is designed for fast and accurate additive manufacturing and possesses the following characteristics:

3D printed parts exhibit the following properties:

The product is designed for fast and accurate additive manufacturing and possesses the following characteristics:

- Viscosity (30C): 900 mPas (cone/plane rheometer)

- Density (liquid resin): 1.12 g/cm3 (ASTM D4052-18a)

- Density (printed part): 1.2 g/cm3 (ASTM D792)

3D printed parts exhibit the following properties:

- E Modulus: 2200 MPa (ASTM D638)

- Tensile Strength: 80 MPa (ASTM D638)

- Elongation at break: 5% (ASTM D638)

- Water absorption (24 hrs): 0.3% (ASTM D570)

調製ノート

Printing process:

1) Preparation of resin - The material should be processed at room temperature. Before usage the material should be shaken well. Pour it slowly in the vat and wait a couple minutes, until smooth, bubble-free surface is obtained before starting the print job.

2) Printing process - As the suitable 3D printer examples and setting parameters stated above are only for general guidance purpose, user should always define the optimal settings according to nneds and printer.

3) Removing parts - Remove the parts carefully from the build platform with a suite able tool, for more information see the Instruction for Use of the used 3D-printer.

4) Cleaning process - The printed pieces can be cleaned firstly immersing it in glycol ether based solvent in an ultrasonic bath filled with water for 2 minutes, followed by rinsing with 2-propanol for a few seconds. Fine structures or holes may be better cleaned by using 2-propanol and a syringe or by separate brushing. The parts should be placed afterwards in a container filled with fresh 2-propanol and subsequently treated in an ultrasonic bath filled with water for 2 minutes. Blow dry the parts with pressure air/nitrogen, until the parts are clean.

5) Drying - Place the parts into a warming cabinet at 40 °C for 30 minutes.

6) Post-curing - The parts require adequate post curing to achieve the optimized final mechanical properties. After each post-curing cycle, the part needs to be flipped to achieve an even curing.

These proceedings are only general guidelines, the optimal printing settings as well as curing time must be defined by the user himself. The post-curing might differ by using different 3D-Printers and different post-curing units may require different settings.

1) Preparation of resin - The material should be processed at room temperature. Before usage the material should be shaken well. Pour it slowly in the vat and wait a couple minutes, until smooth, bubble-free surface is obtained before starting the print job.

2) Printing process - As the suitable 3D printer examples and setting parameters stated above are only for general guidance purpose, user should always define the optimal settings according to nneds and printer.

3) Removing parts - Remove the parts carefully from the build platform with a suite able tool, for more information see the Instruction for Use of the used 3D-printer.

4) Cleaning process - The printed pieces can be cleaned firstly immersing it in glycol ether based solvent in an ultrasonic bath filled with water for 2 minutes, followed by rinsing with 2-propanol for a few seconds. Fine structures or holes may be better cleaned by using 2-propanol and a syringe or by separate brushing. The parts should be placed afterwards in a container filled with fresh 2-propanol and subsequently treated in an ultrasonic bath filled with water for 2 minutes. Blow dry the parts with pressure air/nitrogen, until the parts are clean.

5) Drying - Place the parts into a warming cabinet at 40 °C for 30 minutes.

6) Post-curing - The parts require adequate post curing to achieve the optimized final mechanical properties. After each post-curing cycle, the part needs to be flipped to achieve an even curing.

These proceedings are only general guidelines, the optimal printing settings as well as curing time must be defined by the user himself. The post-curing might differ by using different 3D-Printers and different post-curing units may require different settings.

保管および安定性

Storage Conditions and Disposal Considerations:

Keep container tightly closed in a room temperature (below 30 °C and above 0 °C) and resin away from light. Keep container dry. If Material is not being used fill it back through a filter in the corresponding material bottle. The filter prevents to fill cured pieces or failed prints back into the bottle. Ultracur3D® RG 35 N must be disposed of or incinerated in accordance with local regulations.

Keep container tightly closed in a room temperature (below 30 °C and above 0 °C) and resin away from light. Keep container dry. If Material is not being used fill it back through a filter in the corresponding material bottle. The filter prevents to fill cured pieces or failed prints back into the bottle. Ultracur3D® RG 35 N must be disposed of or incinerated in accordance with local regulations.

法的情報

Ultracur3D is a registered trademark of BASF 3D Printing Solutions GmbH

シグナルワード

Warning

危険有害性情報

危険有害性の分類

Aquatic Chronic 3 - Eye Irrit. 2 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

ターゲットの組織

Respiratory system

保管分類コード

10 - Combustible liquids

WGK

WGK 3

適用法令

試験研究用途を考慮した関連法令を主に挙げております。化学物質以外については、一部の情報のみ提供しています。 製品を安全かつ合法的に使用することは、使用者の義務です。最新情報により修正される場合があります。WEBの反映には時間を要することがあるため、適宜SDSをご参照ください。

毒物及び劇物取締法

劇物

毒物

労働安全衛生法名称等を通知すべき危険物及び有害物

名称等を通知すべき危険物及び有害物

Jan Code

925578-VAR:

925578-500ML:

925578-BULK:

最新バージョンのいずれかを選択してください:

ライフサイエンス、有機合成、材料科学、クロマトグラフィー、分析など、あらゆる分野の研究に経験のあるメンバーがおります。.

製品に関するお問い合わせはこちら(テクニカルサービス)