おすすめの製品

詳細

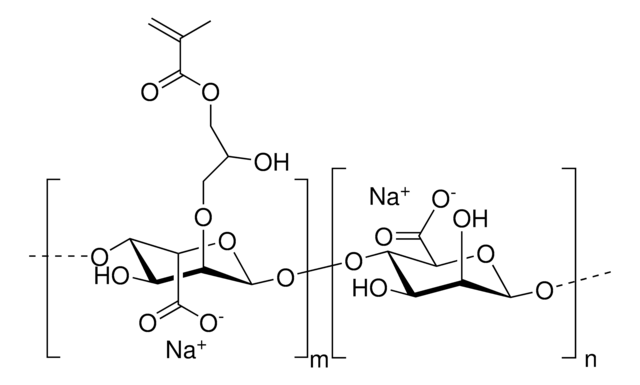

Degree of Substitution: 15-25%

品質水準

フォーム

(Powder or chunk(s) or fibers)

不純物

<10 CFU/g Bioburden (Aerobic)

<10 CFU/g Bioburden (Fungal)

<100 EU/g Endotoxin

色

white to off-white

適合性

conforms to structure for NMR

アプリケーション

This product is a low endotoxin version alginate methacrylate ready to be used in biomedical applications.

Alginate is an anionic polysaccharide that is widely used in pharmaceutical and biomedical applications due to its non-animal origin, low toxicity, biocompatibility, and biodegradability. Alginate hydrogels are commonly used to fabricate tissue engineering scaffolds, bioinks for 3D bioprinting, and nanocarriers for drug & gene delivery. Due to the thermal or photochemical crosslinking of the terminal methacrylates, methacrylate-functionalized alginate can be used to prepare hydrogels resistant to matrix degradation. Properties of the resulting hydrogel (e.g., stiffness, swelling ratio, rate of degradation) can be tuned by alginate molecular weight, degree of methacrylate functionalization, and crosslink density.

Alginate is an anionic polysaccharide that is widely used in pharmaceutical and biomedical applications due to its non-animal origin, low toxicity, biocompatibility, and biodegradability. Alginate hydrogels are commonly used to fabricate tissue engineering scaffolds, bioinks for 3D bioprinting, and nanocarriers for drug & gene delivery. Due to the thermal or photochemical crosslinking of the terminal methacrylates, methacrylate-functionalized alginate can be used to prepare hydrogels resistant to matrix degradation. Properties of the resulting hydrogel (e.g., stiffness, swelling ratio, rate of degradation) can be tuned by alginate molecular weight, degree of methacrylate functionalization, and crosslink density.

保管分類コード

11 - Combustible Solids

WGK

WGK 3

引火点(°F)

Not applicable

引火点(℃)

Not applicable

適用法令

試験研究用途を考慮した関連法令を主に挙げております。化学物質以外については、一部の情報のみ提供しています。 製品を安全かつ合法的に使用することは、使用者の義務です。最新情報により修正される場合があります。WEBの反映には時間を要することがあるため、適宜SDSをご参照ください。

Jan Code

924482-500MG:

924482-VAR:

924482-BULK:

最新バージョンのいずれかを選択してください:

K A Smeds et al.

Journal of biomedical materials research, 54(1), 115-121 (2000-11-15)

In situ photopolymerization is an exciting new technique for tissue engineering. Two photocrosslinkable polysaccharides composed of alginate and hyaluronan are described that upon photolysis form soft, flexible, and viscoelastic hydrogels. The degree of methacrylate modification and thus covalent affects mechanical

Jia Jia et al.

Acta biomaterialia, 10(10), 4323-4331 (2014-07-08)

Recent advances in three-dimensional (3-D) printing offer an excellent opportunity to address critical challenges faced by current tissue engineering approaches. Alginate hydrogels have been used extensively as bioinks for 3-D bioprinting. However, most previous research has focused on native alginates

Kuen Yong Lee et al.

Progress in polymer science, 37(1), 106-126 (2011-11-30)

Alginate is a biomaterial that has found numerous applications in biomedical science and engineering due to its favorable properties, including biocompatibility and ease of gelation. Alginate hydrogels have been particularly attractive in wound healing, drug delivery, and tissue engineering applications

Tarun Agarwal et al.

ACS applied materials & interfaces, 8(47), 32132-32145 (2016-12-10)

Success of bone tissue engineering (BTE) relies on the osteogenic microarchitecture of the biopolymeric scaffold and appropriate spatiotemporal distribution of therapeutic molecules (growth factors and drugs) inside it. However, the existing technologies have failed to address both the issues together.

Eneko Axpe et al.

International journal of molecular sciences, 17(12) (2016-11-30)

Three-dimensional (3D) bioprinting is on the cusp of permitting the direct fabrication of artificial living tissue. Multicellular building blocks (bioinks) are dispensed layer by layer and scaled for the target construct. However, only a few materials are able to fulfill

ライフサイエンス、有機合成、材料科学、クロマトグラフィー、分析など、あらゆる分野の研究に経験のあるメンバーがおります。.

製品に関するお問い合わせはこちら(テクニカルサービス)