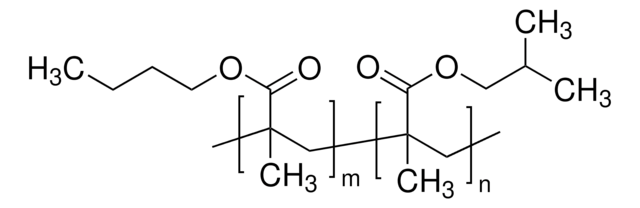

おすすめの製品

詳細

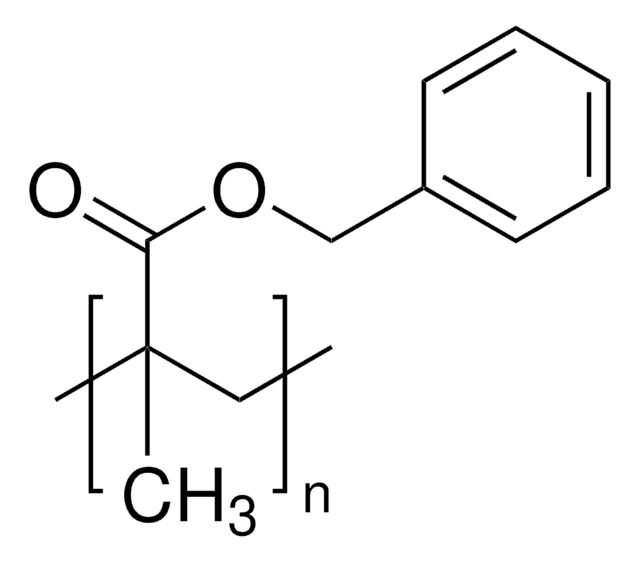

Brookfield Viscosity in 40% toluene: 500-800 cPs

Glass transition temperature onset: 20 °C

Maximum % Moisture: 0.30%

形状

solid (bead)

分子量

Mw 211,000

屈折率

n/D 1.483

密度

1.07 g/mL at 25 °C (lit.)

InChI

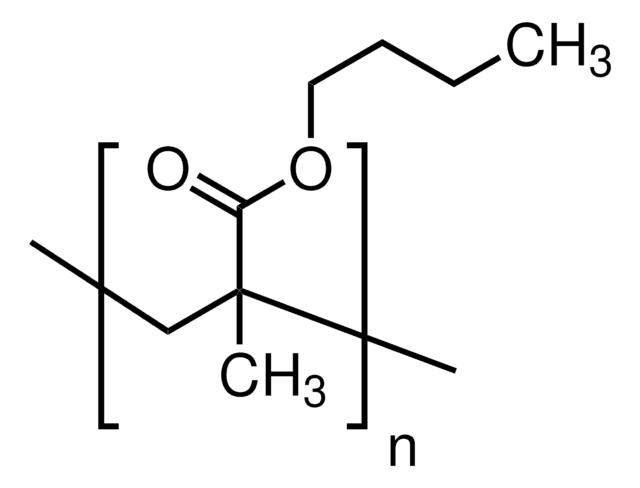

1S/C8H14O2/c1-4-5-6-10-8(9)7(2)3/h2,4-6H2,1,3H3

InChI Key

SOGAXMICEFXMKE-UHFFFAOYSA-N

詳細

Additional Benefit:

Conventional high molecular weight poly(butyl methacrylate) easily forms a fused block that require mechanical force (such as hammering) to break it down into small particles before usage. This product was developed with an anti-blocking technology and comes in an easy-to-use, free flowing, bead form.

Conventional high molecular weight poly(butyl methacrylate) easily forms a fused block that require mechanical force (such as hammering) to break it down into small particles before usage. This product was developed with an anti-blocking technology and comes in an easy-to-use, free flowing, bead form.

アプリケーション

Poly(butyl methacrylate) finds applications in various areas.

It may be used to study the photoluminescence in EuTFC embedded in Poly(butyl methacrylate) (PBMA) polymer films.

It has also been used for coatings, surface modification, solid state battery, silk screen inks, adhesives for plastic and aluminum, plasticizer for hard butyl methacrylate resins, and for improving outdoor durability of vinyl chloride resins in pigmented lacquers.

It may be used to study the photoluminescence in EuTFC embedded in Poly(butyl methacrylate) (PBMA) polymer films.

It has also been used for coatings, surface modification, solid state battery, silk screen inks, adhesives for plastic and aluminum, plasticizer for hard butyl methacrylate resins, and for improving outdoor durability of vinyl chloride resins in pigmented lacquers.

調製ノート

How to Prepare Solutions:

This polymer dissolves at room temperature but requires constant agitation to prevent solvent-swollen granules of polymer from forming agglomerates and sticking to the walls of the vessel.

Important: The polymer beads should be sifted directly into the vortex of the stirred solvent to speed wetting-out and dispersion. Continuous low-shear agitation for periods of 1-12 hours, depending on the grade and concentration of resin, is recommended.

After the solution appears clear in the tank, a sample should be spread out on a Leneta card or glass. After the solvent evaporates and a film forms on the card or glass, there should not be any resin seeds. If there are any seeds, the tank should be agitated further to fully dissolve the resin. Tank agitation should not be stopped (except for sampling) until the film test indicates there are no resin seeds. Any cloudiness or residue may indicate that some polymer remains undissolved. The presence of water in the system can also cause cloudiness.

Solution time can be reduced by heating; most common solvents can be heated to approximately 49°C (120°F) without the need for reflux equipment. High-shear agitation also cuts dissolving time, but requires care to avoid overheating and excessive solvent loss.

This polymer dissolves at room temperature but requires constant agitation to prevent solvent-swollen granules of polymer from forming agglomerates and sticking to the walls of the vessel.

Important: The polymer beads should be sifted directly into the vortex of the stirred solvent to speed wetting-out and dispersion. Continuous low-shear agitation for periods of 1-12 hours, depending on the grade and concentration of resin, is recommended.

After the solution appears clear in the tank, a sample should be spread out on a Leneta card or glass. After the solvent evaporates and a film forms on the card or glass, there should not be any resin seeds. If there are any seeds, the tank should be agitated further to fully dissolve the resin. Tank agitation should not be stopped (except for sampling) until the film test indicates there are no resin seeds. Any cloudiness or residue may indicate that some polymer remains undissolved. The presence of water in the system can also cause cloudiness.

Solution time can be reduced by heating; most common solvents can be heated to approximately 49°C (120°F) without the need for reflux equipment. High-shear agitation also cuts dissolving time, but requires care to avoid overheating and excessive solvent loss.

シグナルワード

Warning

危険有害性情報

危険有害性の分類

Skin Sens. 1

保管分類コード

11 - Combustible Solids

WGK

WGK 3

引火点(°F)

Not applicable

引火点(℃)

Not applicable

適用法令

試験研究用途を考慮した関連法令を主に挙げております。化学物質以外については、一部の情報のみ提供しています。 製品を安全かつ合法的に使用することは、使用者の義務です。最新情報により修正される場合があります。WEBの反映には時間を要することがあるため、適宜SDSをご参照ください。

PRTR

第二種指定化学物質

労働安全衛生法名称等を表示すべき危険物及び有害物

名称等を表示すべき危険物及び有害物

労働安全衛生法名称等を通知すべき危険物及び有害物

名称等を通知すべき危険物及び有害物

Jan Code

910716-BULK:

910716-5G:

910716-250G:

910716-VAR:

最新バージョンのいずれかを選択してください:

Kamil Awsiuk et al.

Biomacromolecules, 20(6), 2185-2197 (2019-04-25)

Poly( n-butyl methacrylate) (PBMA) or poly( n-butyl acrylate) (PBA)-grafted brush coatings attached to glass were successfully prepared using atom-transfer radical polymerization "from the surface". The thicknesses and composition of the PBMA and PBA coatings were examined using ellipsometry and time-of-flight

A polymeric coat for nanodroplets.

Anna Carlmark

Nature nanotechnology, 14(7), 640-641 (2019-05-22)

A poly(butyl methacrylate)/graphene oxide/TiO2 nanocomposite coating with superior corrosion protection for AZ31 alloy in chloride solution

Nazeer A A, et al.

Chemical Engineering Journal, 361, 485-498 (2019)

Micro and nanometer scale photopatterning of self-assembled monolayers

Leggett G J

Material Matters, 6(1), 22-29 (2011)

資料

Synthesis and Applications of Graphene Nanoribbons Synthesized

ライフサイエンス、有機合成、材料科学、クロマトグラフィー、分析など、あらゆる分野の研究に経験のあるメンバーがおります。.

製品に関するお問い合わせはこちら(テクニカルサービス)