445746

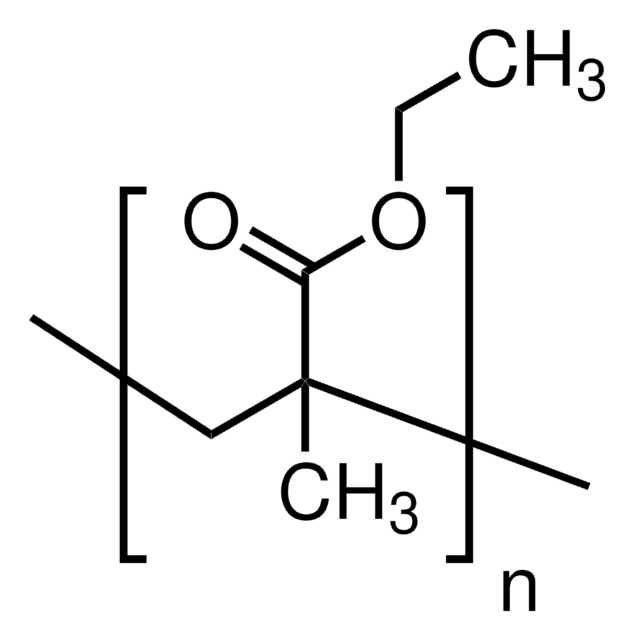

Poly(methyl methacrylate)

average Mw ~350,000 by GPC

Sinonimo/i:

PMMA

About This Item

Prodotti consigliati

Forma fisica

powder

Livello qualitativo

Temp. autoaccensione

580 °F

PM

average Mw ~350,000 by GPC

Viscosità ridotta

150-160 cm3/g(20 °C)(lit.)

Numero di acido

<1 mg KOH/g

Temp. transizione

Tg (DSC) 105 °C (midpoint)

Solubilità

alcohols and aliphatic hydrocarbons: insoluble

esters, ketones, aromatics and glycol ethers: soluble

Densità

1.17 g/mL at 25 °C

InChI

1S/C5H9O2/c1-4(2)5(6)7-3/h1-3H3

PMAMJWJDBDSDHV-UHFFFAOYSA-N

Cerchi prodotti simili? Visita Guida al confronto tra prodotti

Descrizione generale

Applicazioni

Caratteristiche e vantaggi

Codice della classe di stoccaggio

11 - Combustible Solids

Classe di pericolosità dell'acqua (WGK)

nwg

Dispositivi di protezione individuale

Eyeshields, Gloves, type N95 (US)

Scegli una delle versioni più recenti:

Possiedi già questo prodotto?

I documenti relativi ai prodotti acquistati recentemente sono disponibili nell’Archivio dei documenti.

I clienti hanno visto anche

Articoli

Professor Aran (Claremont University, USA) thoroughly discusses the engineering of graphene based materials through careful functionalization of graphene oxide, a solution processable form of graphene.

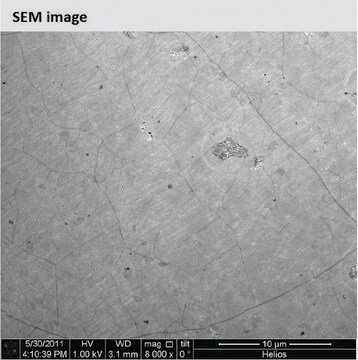

Developed in the last several years, fluorescence quenching microscopy (FQM) has enabled rapid, inexpensive, and high-fidelity visualization of two-dimensional (2D) materials such as graphene-based sheets and MoS2.

We will explore the technological advances that have contributed toward the progress of 3DP of tissue engineering scaffolds, current materials used to create 3DP scaffolds, and the challenges that remain.

Il team dei nostri ricercatori vanta grande esperienza in tutte le aree della ricerca quali Life Science, scienza dei materiali, sintesi chimica, cromatografia, discipline analitiche, ecc..

Contatta l'Assistenza Tecnica.