182087

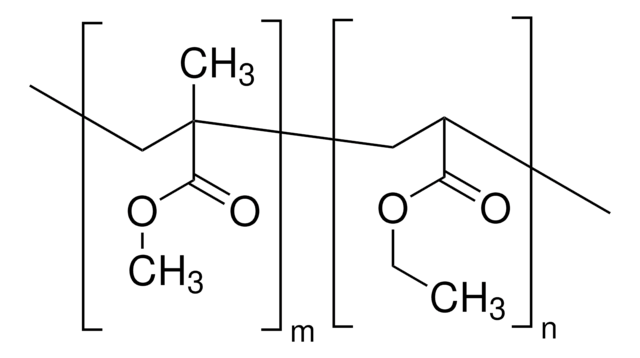

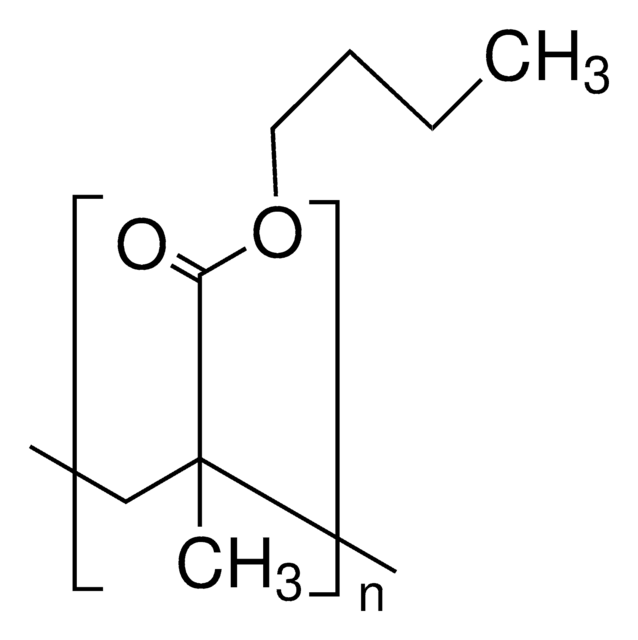

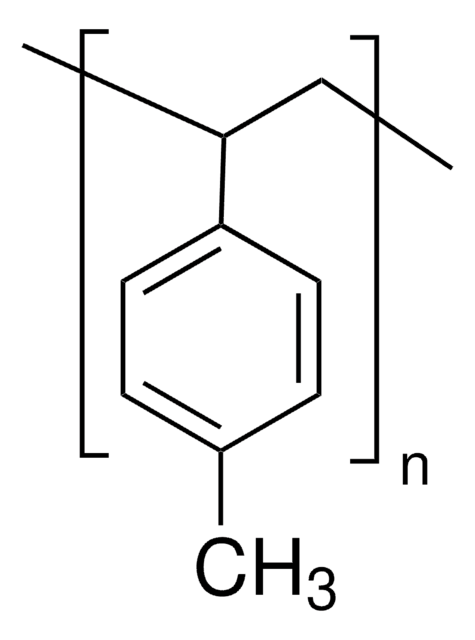

Poly(ethyl methacrylate)

average Mw ~515,000 by GPC, powder

Sinonimo/i:

Ethyl methacrylate homopolymer, Poly(ethyl 2-methyl-2-propeonate)

About This Item

Prodotti consigliati

Stato

powder

PM

average Mw ~515,000 by GPC

Indice di rifrazione

n20/D 1.485

Viscosità intrinseca

0.80 dL/g(lit.)

Temp. transizione

Tg 63 °C

Densità

1.11 g/mL at 25 °C

Stringa SMILE

CCOC(=O)C(C)=C

InChI

1S/C6H10O2/c1-4-8-6(7)5(2)3/h2,4H2,1,3H3

SUPCQIBBMFXVTL-UHFFFAOYSA-N

Cerchi prodotti simili? Visita Guida al confronto tra prodotti

Descrizione generale

Applicazioni

Codice della classe di stoccaggio

10 - Combustible liquids

Classe di pericolosità dell'acqua (WGK)

WGK 3

Punto d’infiammabilità (°F)

Not applicable

Punto d’infiammabilità (°C)

Not applicable

Scegli una delle versioni più recenti:

Certificati d'analisi (COA)

Non trovi la versione di tuo interesse?

Se hai bisogno di una versione specifica, puoi cercare il certificato tramite il numero di lotto.

Possiedi già questo prodotto?

I documenti relativi ai prodotti acquistati recentemente sono disponibili nell’Archivio dei documenti.

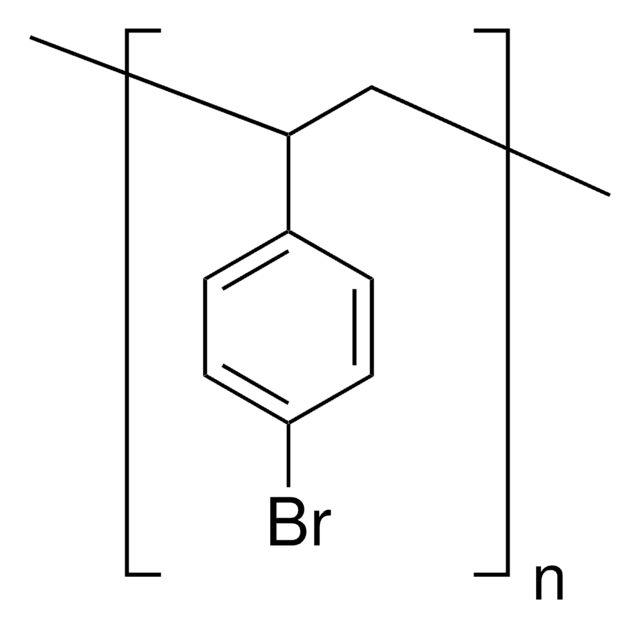

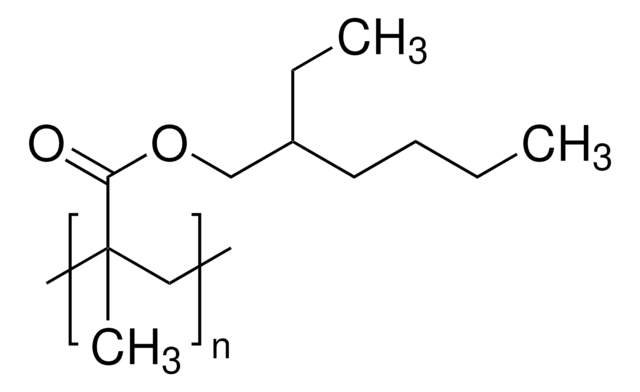

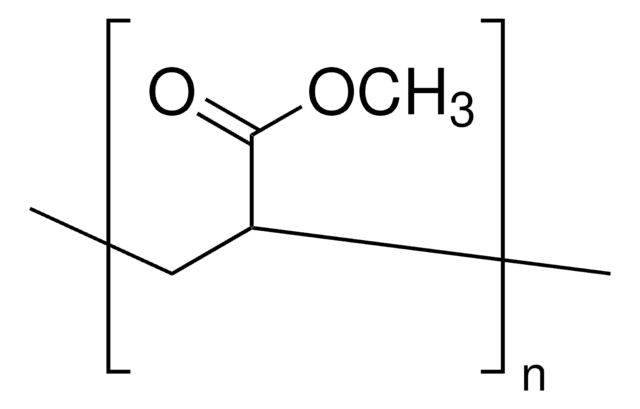

I clienti hanno visto anche

Articoli

Self-assembled monolayers (SAMs) have attracted enormous interest for a wide variety of applications in micro- and nano-technology. In this article, we compare the benefits of three different classes of SAM systems (alkylthiolates on gold.

Il team dei nostri ricercatori vanta grande esperienza in tutte le aree della ricerca quali Life Science, scienza dei materiali, sintesi chimica, cromatografia, discipline analitiche, ecc..

Contatta l'Assistenza Tecnica.