905410

TissueFab® bioink

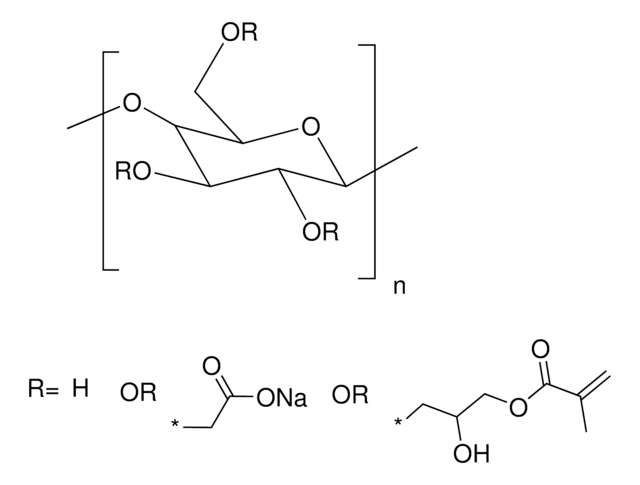

Alg(Gel)ma -UV/365 nm

Sinônimo(s):

GelMA-alginate bioink

About This Item

Produtos recomendados

descrição

0.2 μm sterile filtered

suitable for 3D bioprinting applications

Formulário

viscous liquid

embalagem

1 ea of 10 mL

Impurezas

≤5 CFU/g Bioburden (Fungal)

≤5 CFU/g Bioburden (Total Aerobic)

cor

colorless to pale yellow

pH

6.5-7.5

aplicação(ões)

3D bioprinting

temperatura de armazenamento

2-8°C

Procurando produtos similares? Visita Guia de comparação de produtos

Descrição geral

Aplicação

Embalagem

Outras notas

- Optimize printing conditions (e.g., nozzle diameter, printing speed, printing pressure, temperature, cell density) for the features of your 3D printer and your application.

- Reduce bubble formation. Air bubbles in bioink may hamper bioprinting. Carefully handle the bioink when you mix and transfer it to avoid bubble formation. Do not vortex or shake vigorously.

- UV light Crosslinking. Position the light source directly above the printed structure. Lower intensity light sources will require shorter distances and longer exposure times to complete crosslinking. Recommended conditions: Place an 800 mW/cm2 light source 8 cm above the printed structure and expose for 30 to 60 s.

Procedure

1. Prepare bioink solution: Warm TissueFab® - GelAlg-UV bioink in a water bath or incubator set to 37 °C for 30 minutes or until the bioink becomes fluid. Gently invert the bioink to make a homogeneous solution. DO NOT vortex or shake vigorously.

2. Prepare bioink-cell solution: Resuspend the cell pellet at the desired cell density with the bioink solution by gently pipetting up and down. Typical cell density for extrusion-based bioprinting is 1 to 5 x 106 cells/mL. Load the bioink-cell solution into the desired printer cartridge.

3. Bioprint: Cool the filled printer cartridge below 23 °C to induce gelation, using a temperature controlled printhead or place the cartridge at 4 °C for a few minutes. If print bed temperature control is available, set temperature to 20 °C. Follow the 3D printer manufacturer′s instructions. Load the print cartridge onto the 3D printer and print directly onto a Petri dish or into multi-well plates. Adjust the flow according to nozzle diameter, printing speed, printing pressure, and temperature. For optimal results, print under a gentle flow of 200 mM CaCl2 solution. A portable humidifier may be used to maintain the flow of the CaCl2 solution.

4. Crosslink: To photocrosslink, place the UV light source directly above the 3D-bioprinted structure and expose the structure to UV light (wavelength 365 nm). Use the appropriate distance settings and exposure times for your bioprinter. To chemically crosslink the printed structure, add 100mM CaCl2 in PBS for 1 minute. Rinse with PBS twice.

5. Culture cells: Culture the bioprinted tissue with appropriate cell culture medium following standard tissue culture procedures.

Informações legais

Código de classe de armazenamento

10 - Combustible liquids

Classe de risco de água (WGK)

WGK 3

Escolha uma das versões mais recentes:

Certificados de análise (COA)

Não está vendo a versão correta?

Se precisar de uma versão específica, você pode procurar um certificado específico pelo número do lote ou da remessa.

Já possui este produto?

Encontre a documentação dos produtos que você adquiriu recentemente na biblioteca de documentos.

Os clientes também visualizaram

Artigos

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Nossa equipe de cientistas tem experiência em todas as áreas de pesquisa, incluindo Life Sciences, ciência de materiais, síntese química, cromatografia, química analítica e muitas outras.

Entre em contato com a assistência técnica