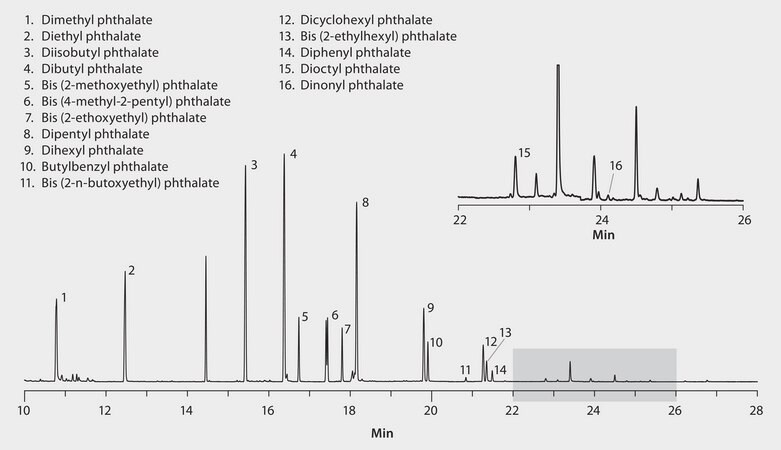

GC Analysis of Phthalate Esters in Corn Oil (Spiked) on SLB®-5ms after SPME with a 100 μm PDMS Fiber

Materials

Analytical column

SPME fiber

SPME fiber assembly Polydimethylsiloxane (PDMS)

df 7 μm(PDMS, needle size 24 ga, for use with manual holderSPME fiber assembly Polydimethylsiloxane (PDMS)

df 100 μm(PDMS, for use with autosampler, needle size 23 gaSPME fiber assembly Polydimethylsiloxane (PDMS)

df 100 μm(PDMS, needle size 24 ga, for use with manual holderStandard

Bis(2-ethylhexyl) phthalate

certified reference material, TraceCERT®, Manufactured by: Sigma-Aldrich Production GmbH, SwitzerlandDibutyl phthalate

certified reference material, TraceCERT®, Manufactured by: Sigma-Aldrich Production GmbH, SwitzerlandDiisobutyl phthalate

certified reference material, TraceCERT®, Manufactured by: Sigma-Aldrich Production GmbH, Switzerlandrelated product

Vials, screw top, clear glass (vial only)

volume 15 mL, clear glass vial, thread for 18-400, pkg of 100 eaScrew cap, phenolic, with open center

black phenolic hole cap, for use with 15 mL vial with 18-400 thread, pkg of 100 eaSepta, tan PTFE/silicone

white tan PTFE/silicone, diam. × thickness 16 mm × 0.090 in., for use with 15 mL vial, pkg of 100 eaCONDITIONS

sample/matrix

corn oil spiked with phthalate esters at 500 μg/kg

SPME fiber

100 μm PDMS (57300-U)

extraction

headspace, 95 °C (measured in headspace)

desorption process

260 °C for 4 min

column

F.S. CAP. SLB-5ms 20 m x 0.18 mm I.D., 0.18 μm (28564-U)

oven

60 °C (1 min), 10 °C/min to 330 °C (10 min)

inj. temp.

260 °C

carrier gas

helium, 0.6 mL/min, constant

liner

0.75 mm I.D. SPME

sample

Corn oil

Description

Analysis Note

In this application, SPME was used for the analysis of phthalate esters from oily samples, specifically the oil-based flavor packets included with ramen noodle kits. Spiked samples of corn oil and flavored oils included with ramen noodle kits were analyzed using high temperature SPME headspace extraction using a 100 μm PDMS fiber which was then directly desorbed into the GC/MS system. Calibration standards were prepared in corn oil, and spiked samples of chicken and beef oil-based flavors were analyzed. The SLB-5ms GC columns provide consistently low-bleed, inert, efficient, and durable separations.

Legal Information

SLB is a registered trademark of Merck KGaA, Darmstadt, Germany