791547

Titania paste, transparent

Synonym(s):

Greatcell Solar®, TiO2 paste

About This Item

Recommended Products

description

Crystal Structure: > 99% anatase (analysis carried out on starting material, prior to paste manufacture)

form

paste (yellow)

concentration

19.0 wt. %

avg. part. size

20 nm (active)

viscosity

40000-55000 mPa.s(20 °C) (Analysis carried out at 20°C with 20mm 4 degree cone/plate; 40 s-1))

SMILES string

[Ti](=O)=O

InChI

1S/2O.Ti

InChI key

GWEVSGVZZGPLCZ-UHFFFAOYSA-N

General description

Application

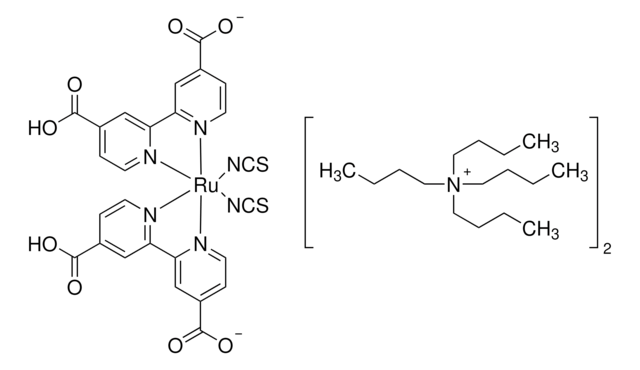

Transparent Titania Paste is formulated to yield sintered film thicknesses of 6-7μm when screen printed with a 43T mesh. Transparent Titania Paste has highly dispersed and stable anatase nanoparticles.

It is optimised for screen printing using a synthetic 43T mesh screen (or similar). After drying; this paste must be fired at or above 500°C. This results in a transparent sintered layer; with a film thickness of approximately 6-7μm for one printed layer and ~12μm for two printed layers; when using a 43T mesh screen.

The paste exhibits optimal rheological properties that provide good surface uniformity and contains organic binders specially formulated to provide versatile porosity suitable for a range of dye/electrolyte systems.

Storage: Store in the dark at 20°C

Legal Information

signalword

Warning

hcodes

Hazard Classifications

Eye Irrit. 2 - Skin Irrit. 2

Storage Class

10 - Combustible liquids

wgk_germany

WGK 1

flash_point_f

195.8 °F - closed cup

flash_point_c

91 °C - closed cup

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Professor Shinar (Iowa State University, USA) summarizes the developments of a variety of sensor configurations based on organic and hybrid electronics, as low-cost, disposable, non-invasive, wearable bioelectronics for healthcare.

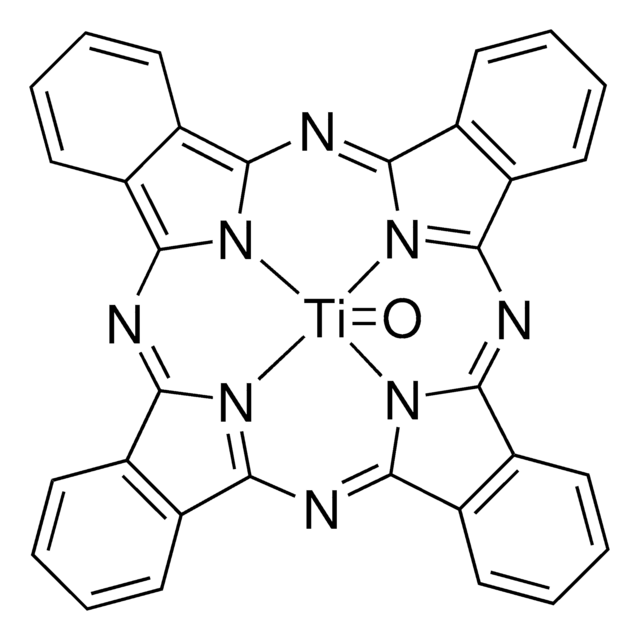

Organic photovoltaics (OPVs) represent a low-cost, lightweight, and scalable alternative to conventional solar cells. While significant progress has been made in the development of conventional bulk heterojunction cells, new approaches are required to achieve the performance and stability necessary to enable commercially successful OPVs.

While dye sensitization as the basis for color photography has been accepted for a very long time,1 attempts to use this principle for the conversion of solar light to electricity generally had resulted only in very low photocurrents, below 100 nA/cm

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service