WHA10401106

Whatman® nitrocellulose NC45 filter discs 0.45 μm pore size

white, hydrophilic, 100 ea, 25 mm diam

Synonim(y):

Z697117, polycarbonate filter, polycarbonate membrane

About This Item

Polecane produkty

Nazwa produktu

Whatman® nitrocellulose membrane filters, NC45 Membrane Circles, diam. 25 mm, pore size 0.45 μm

sterylność

non-sterile

opakowanie

pkg of 100 ea

producent / nazwa handlowa

Whatman 10401106

Whatman Article No. 28414958 (US reference)

Średnica

25 mm

wielkość porów

0.45 μm

Szukasz podobnych produktów? Odwiedź Przewodnik dotyczący porównywania produktów

Powiązane kategorie

Cechy i korzyści

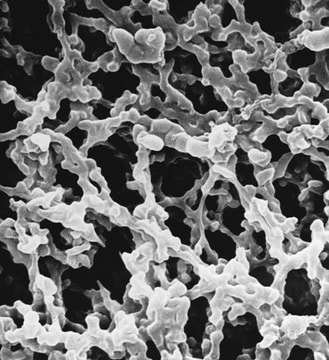

- Narrow pore size distribution for improved surface capture and analysis.

- Low levels of extractables to ensure sample integrity.

Inne uwagi

Informacje prawne

Hasło ostrzegawcze

Warning

Zwroty wskazujące rodzaj zagrożenia

Zwroty wskazujące środki ostrożności

Kod klasy składowania

11 - Combustible Solids

Wybierz jedną z najnowszych wersji:

Certyfikaty analizy (CoA)

Przepraszamy, ale COA dla tego produktu nie jest aktualnie dostępny online.

Proszę o kontakt, jeśli potrzebna jest pomoc Obsługa Klienta

Masz już ten produkt?

Dokumenty związane z niedawno zakupionymi produktami zostały zamieszczone w Bibliotece dokumentów.

Nasz zespół naukowców ma doświadczenie we wszystkich obszarach badań, w tym w naukach przyrodniczych, materiałoznawstwie, syntezie chemicznej, chromatografii, analityce i wielu innych dziedzinach.

Skontaktuj się z zespołem ds. pomocy technicznej