BASMF2052

Ag/AgCl (3M NaCl) Reference Electrode

Zaloguj sięWyświetlanie cen organizacyjnych i kontraktowych

About This Item

Kod UNSPSC:

12352300

Polecane produkty

Powiązane kategorie

Opis ogólny

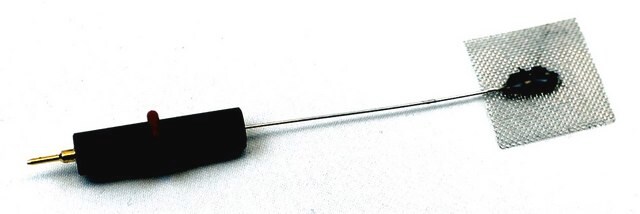

RE-5B Ag/AgCl (3M NaCl) Reference Electrode with Flexible Connector

TESTING THE PERFORMANCE OF Ag/AgCl

REMOVING THE SHEATH: Every Ag/AgCl reference electrode is shipped with a yellow plastic sheath that covers the porous frit and slows drying. Immediately remove the sheath upon receipt and store electrode in appropriate solution. It’s recommend soaking the tips in the 3M salt solution for about an hour after removing the protective cover. Please check that there are no bubbles on the electrode frit. If there are bubbles on the frit on the inside of the electrode, you will need to flick or tap the side of the electrode near the frit to dislodge the bubbles so that they rise to the top of the electrode. Bubbles on the frit can cause an unsteady signal and damage the electrode. The redox potential for the Ag/AgCl (3M NaCl) Reference Electrode is +0.209 V (vs. NHE). Be extremely careful when removing the plastic sheath from the reference electrode. DO NOT roll the plastic down and pull off. The best method is to cut the length of the plastic sheath with scissors and peal the sheath off the electrode. Start with a small cut at the upper edge of the sheath, pull to the side, and continue to cut and peal to the tip. A scalpel may be used, but there is greater chance of damaging the heat-shrink tubing.

DISLODGING BUBBLES: Bubbles lodged in the tip may prevent electrical contact with the electrolyte and may damage the working electrode. Bubbles can be dislodged by holding the top of the electrode with one hand and tapping the electrode near the frit tip until the bubbles rise to the top.

REGENERATING THE

STORING REFERENCE ELECTRODES: After the sheath is removed, store the electrode tip in 3 M NaCl or 3M KCl solution. We do recommend storage vial for efficient storage. Only the tip needs to be immersed in the storage solution; the connecting pin needs to be kept dry to minimize corrosion. The reference electrodes are easily ruined by drying and will naturally change with use due to the ion and solvent transport across the porous frit. This rate of change is a function of the difference in composition between the sample solution vs. the filling solution and the amount of time not immersed in the storage solution.

TESTING THE PERFORMANCE OF Ag/AgCl

REMOVING THE SHEATH: Every Ag/AgCl reference electrode is shipped with a yellow plastic sheath that covers the porous frit and slows drying. Immediately remove the sheath upon receipt and store electrode in appropriate solution. It’s recommend soaking the tips in the 3M salt solution for about an hour after removing the protective cover. Please check that there are no bubbles on the electrode frit. If there are bubbles on the frit on the inside of the electrode, you will need to flick or tap the side of the electrode near the frit to dislodge the bubbles so that they rise to the top of the electrode. Bubbles on the frit can cause an unsteady signal and damage the electrode. The redox potential for the Ag/AgCl (3M NaCl) Reference Electrode is +0.209 V (vs. NHE). Be extremely careful when removing the plastic sheath from the reference electrode. DO NOT roll the plastic down and pull off. The best method is to cut the length of the plastic sheath with scissors and peal the sheath off the electrode. Start with a small cut at the upper edge of the sheath, pull to the side, and continue to cut and peal to the tip. A scalpel may be used, but there is greater chance of damaging the heat-shrink tubing.

DISLODGING BUBBLES: Bubbles lodged in the tip may prevent electrical contact with the electrolyte and may damage the working electrode. Bubbles can be dislodged by holding the top of the electrode with one hand and tapping the electrode near the frit tip until the bubbles rise to the top.

REGENERATING THE

STORING REFERENCE ELECTRODES: After the sheath is removed, store the electrode tip in 3 M NaCl or 3M KCl solution. We do recommend storage vial for efficient storage. Only the tip needs to be immersed in the storage solution; the connecting pin needs to be kept dry to minimize corrosion. The reference electrodes are easily ruined by drying and will naturally change with use due to the ion and solvent transport across the porous frit. This rate of change is a function of the difference in composition between the sample solution vs. the filling solution and the amount of time not immersed in the storage solution.

Zastosowanie

- Enhanced Electrochemical and Physical Properties of Ag/AgCl Planar Reference Electrodes in Potentiometric Sensors by Graphite Oxide Layer: This study presents a modified Ag/AgCl planar reference electrode enhanced with a graphite oxide layer, showing improved stability and electrochemical performance (TSV Nguyen et al., 2019).

- Fabrication of a 3D-printed porous junction for Ag|AgCl| gel-KCl reference electrode: Discusses the design and performance of a 3D-printed Ag/AgCl reference electrode with a gel-KCl electrolyte, aimed at enhancing usability and reliability in various electrolyte solutions (SM Sibug-Torres et al., 2020).

- Fabrication and characterization of a stabilized thin film Ag/AgCl reference electrode: Explores a novel thin film Ag/AgCl reference electrode modified with self-assembled monolayer of alkane thiol chains for rapid sensor applications (T Rahman, T Ichiki, 2017).

- A novel flexible Ag/AgCl quasi-reference electrode: Research on a new flexible Ag/AgCl reference electrode based on silver nanowires, aiming for applications in electrophysiology and sensitive electrochemical measurements (J Sun et al., 2020).

- A solid-state thin-film Ag/AgCl reference electrode coated with graphene oxide: Details the development of a solid-state thin-film Ag/AgCl reference electrode, enhanced with a graphene oxide coating for improved durability and performance in pH sensing (TY Kim et al., 2015).

Informacje prawne

Product of Bioanalytical Systems, Inc.

This page may contain text that has been machine translated.

Zwroty wskazujące rodzaj zagrożenia

Zwroty wskazujące środki ostrożności

Klasyfikacja zagrożeń

Aquatic Chronic 3

Kod klasy składowania

13 - Non Combustible Solids

Klasa zagrożenia wodnego (WGK)

WGK 3

Temperatura zapłonu (°F)

Not applicable

Temperatura zapłonu (°C)

Not applicable

Certyfikaty analizy (CoA)

Poszukaj Certyfikaty analizy (CoA), wpisując numer partii/serii produktów. Numery serii i partii można znaleźć na etykiecie produktu po słowach „seria” lub „partia”.

Masz już ten produkt?

Dokumenty związane z niedawno zakupionymi produktami zostały zamieszczone w Bibliotece dokumentów.

Nasz zespół naukowców ma doświadczenie we wszystkich obszarach badań, w tym w naukach przyrodniczych, materiałoznawstwie, syntezie chemicznej, chromatografii, analityce i wielu innych dziedzinach.

Skontaktuj się z zespołem ds. pomocy technicznej