921491

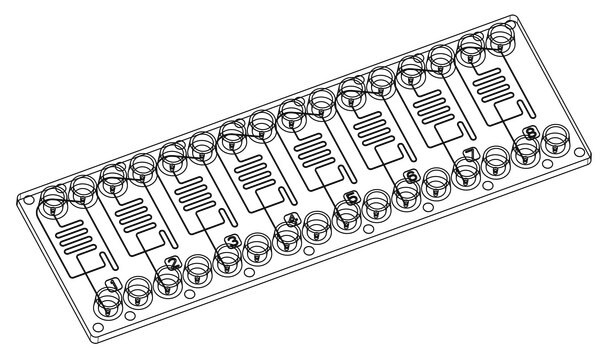

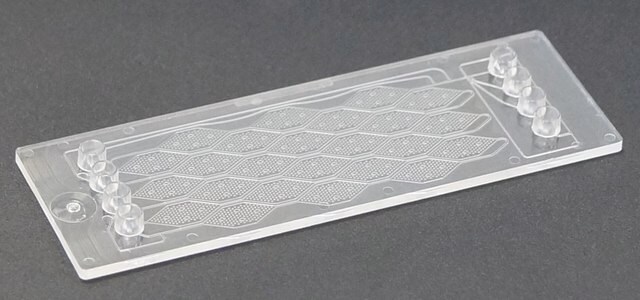

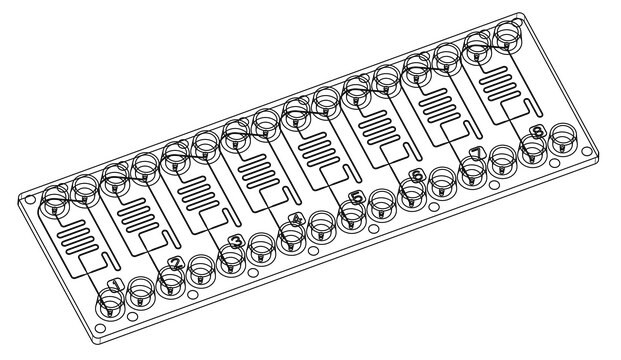

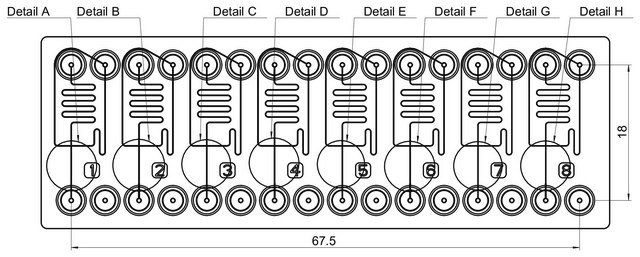

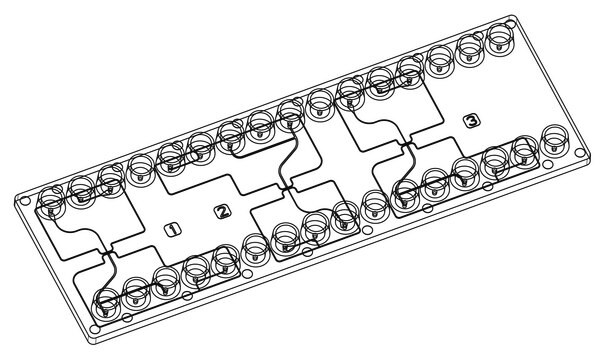

Droplet generator chip - One channel design

Fluidic 162, PC

Synonim(y):

Mikrocząsteczka, Mikroprzepływowy, Nanocząsteczka

Zaloguj sięWyświetlanie cen organizacyjnych i kontraktowych

About This Item

Kod UNSPSC:

42142600

NACRES:

NA.23

Polecane produkty

opis

Microfludic chip x1

Szukasz podobnych produktów? Odwiedź Przewodnik dotyczący porównywania produktów

Zastosowanie

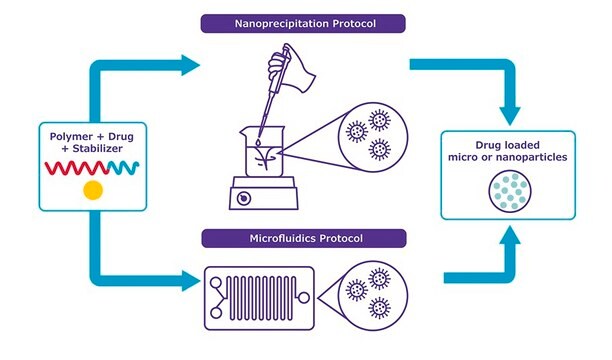

Mikroprzepływowe generowanie kropelek może wytwarzać wysoce monodyspersyjne kropelki z wysoką częstotliwością (do setek kHz). Zainteresowanie systemami mikroprzepływowymi opartymi na kropelkach znacznie wzrosło, ponieważ mikroprzepływy oferują możliwość obsługi bardzo małych objętości (μl do fl) płynów, zapewniają lepsze mieszanie, hermetyzację, sortowanie i wykrywanie. Mikroprzepływy mogą być wykorzystywane do eksperymentów o wysokiej przepustowości. Kropelki oparte na mikroprzepływach mają wiele różnorodnych zastosowań, takich jak synteza cząstek i analiza chemiczna. Wysoce kontrolowana produkcja kropelek umożliwia również analizę pojedynczych komórek lub testowanie leków.

Układ generatora kropel - konstrukcja jednokanałowa, Fluidic 162, PC jest wykonany z PC (poliwęglanu) i posiada dwukanałowe skrzyżowanie w obszarze generowania kropel oraz jeden kanał zbierania kropel. Podobnie jak większość generatorów kropel o podwójnej geometrii krzyżowej, Fluidic 162 może być również używany do eksperymentów z pojedynczym krzyżem, po prostu nie łącząc odpowiednich kanałów, ale zamykając ich interfejsy za pomocą zatyczek. Przy dyszy o średnicy 70 μm można uzyskać krople o średnicy od 80 μm (∼260 pl) do 210 μm. Stały rozmiar kropli może być generowany przy różnych prędkościach przepływu poprzez zachowanie stosunku fazy olejowej do wodnej. Zwiększając natężenie przepływu fazy olejowej przy stałym natężeniu przepływu fazy wodnej, można precyzyjnie dostroić wielkość kropli.

Układ generatora kropel - konstrukcja jednokanałowa, Fluidic 162, PC jest wykonany z PC (poliwęglanu) i posiada dwukanałowe skrzyżowanie w obszarze generowania kropel oraz jeden kanał zbierania kropel. Podobnie jak większość generatorów kropel o podwójnej geometrii krzyżowej, Fluidic 162 może być również używany do eksperymentów z pojedynczym krzyżem, po prostu nie łącząc odpowiednich kanałów, ale zamykając ich interfejsy za pomocą zatyczek. Przy dyszy o średnicy 70 μm można uzyskać krople o średnicy od 80 μm (∼260 pl) do 210 μm. Stały rozmiar kropli może być generowany przy różnych prędkościach przepływu poprzez zachowanie stosunku fazy olejowej do wodnej. Zwiększając natężenie przepływu fazy olejowej przy stałym natężeniu przepływu fazy wodnej, można precyzyjnie dostroić wielkość kropli.

Ta strona może zawierać tekst przetłumaczony maszynowo.

Wybierz jedną z najnowszych wersji:

Certyfikaty analizy (CoA)

Lot/Batch Number

It looks like we've run into a problem, but you can still download Certificates of Analysis from our Dokumenty section.

Proszę o kontakt, jeśli potrzebna jest pomoc Obsługa Klienta

Masz już ten produkt?

Dokumenty związane z niedawno zakupionymi produktami zostały zamieszczone w Bibliotece dokumentów.

Recent advances of controlled drug delivery using microfluidic platforms.

Li X, et al.

Drug delivery, 128, 3-28 (2018)

Microfluidic-assisted fabrication of carriers for controlled drug delivery.

Santos H A, et al.

Lab on a chip, 17, 1856-1883 (2017)

Sharma T Sanjay et al.

Advanced drug delivery reviews, 128, 3-28 (2017-09-19)

Conventional systematically-administered drugs distribute evenly throughout the body, get degraded and excreted rapidly while crossing many biological barriers, leaving minimum amounts of the drugs at pathological sites. Controlled drug delivery aims to deliver drugs to the target sites at desired

Dongfei Liu et al.

Lab on a chip, 17(11), 1856-1883 (2017-05-10)

The microfluidic technique has brought unique opportunities toward the full control over the production processes for drug delivery carriers, owing to the miniaturisation of the fluidic environment. In comparison to the conventional batch methods, the microfluidic setup provides a range

Nasz zespół naukowców ma doświadczenie we wszystkich obszarach badań, w tym w naukach przyrodniczych, materiałoznawstwie, syntezie chemicznej, chromatografii, analityce i wielu innych dziedzinach.

Skontaktuj się z zespołem ds. pomocy technicznej