추천 제품

설명

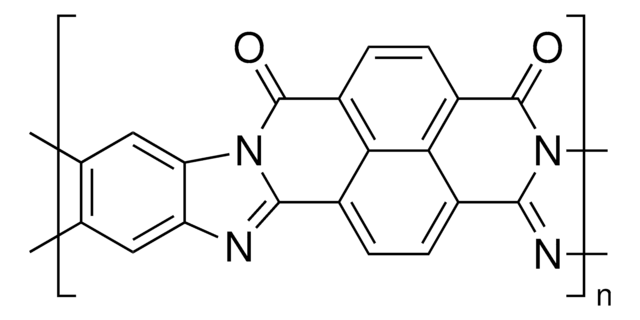

Thermal stability (1h in N2): Up to 350 °C

Quality Level

구성

butanol (solvent)

작업 기능

4.22 eV, UPS analysis

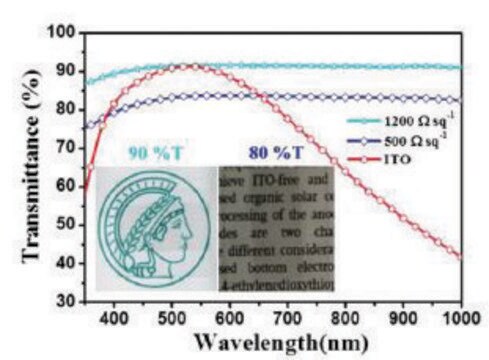

전도도

((in plane): Up to 5 S/cm)

((out of plane): Up to 0.1 S/cm)

λmax

350 nm±5 nm

600 nm±5 nm

애플리케이션

Our n-type BBL:PEI ink is an butanol-based, eco-friendly and halogen-free precursor for high electron conductive and thermally stable (24 hours at 200 °C or 1 hour at 350 °C in N2) thin films. This product has a fixed solid content of 0.2 wt%. This ratio between BBL:PEI (50 % PEI content) results in the highest conductivity. It enables conductivity of up to 8 S/cm and Seebeck coefficient of at least -60 µV/K. Resistant to prolonged air exposure.

It is compatible with large scale deposition methods, such as spray-coating and inkjet. The BBL:PEI ink can be further diluted for casting thin films in various thickness. BBL:PEI thin films were fabricated by spray-casting in air, followed by annealing at 140 °C for 2 h inside a nitrogen-filled glovebox or under vacuum to produce conducting films. The BBL:PEI ink, when processed, forms a high electron conducting n-type film that can be implemented as conducting layer in solar cells, thermoelectric generators, light-emitting diodes, or logic applications:

It is compatible with large scale deposition methods, such as spray-coating and inkjet. The BBL:PEI ink can be further diluted for casting thin films in various thickness. BBL:PEI thin films were fabricated by spray-casting in air, followed by annealing at 140 °C for 2 h inside a nitrogen-filled glovebox or under vacuum to produce conducting films. The BBL:PEI ink, when processed, forms a high electron conducting n-type film that can be implemented as conducting layer in solar cells, thermoelectric generators, light-emitting diodes, or logic applications:

- OPV – Charge extracting layer in Organic Solar Cells

- SuperCapacitors – Negatrode in Organic Supercapacitors

- OECT – Active material in Organic Electrochemical Transistors

- OLED – Charge injecting layer in Organic Light Emitting Diodes

제조 메모

- Always store the ink in dark and at ambient temperature.

- Shake the bottle vigorously to ensure an optimal dispersion of the ink prior to processing (by using ultrasonic bath for instance; 100 to 300 W for 30 min).

- The ink is primarily designed to be spray-casted, with an air-gun or similar spraying methods.

- The films are stable in air up to 2 days before its thermal activation.

- Always proceed with the thermal activation of ink under inert environments (vacuum, N2, Ar, etc.) or if properly encapsulated with an air-stable compound.

- Thermally activated films of our ink films are not affected by chloroform, chlorobenzene, 1,8-diiodooctane, dimethylformamide and dimethyl sulfoxide.

신호어

Danger

유해 및 위험 성명서

Hazard Classifications

Acute Tox. 4 Oral - Eye Dam. 1 - Flam. Liq. 3 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

표적 기관

Central nervous system, Respiratory system

Storage Class Code

3 - Flammable liquids

WGK

WGK 2

Flash Point (°F)

95.0 °F

Flash Point (°C)

35 °C

가장 최신 버전 중 하나를 선택하세요:

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.

![[6,6]-Phenyl C61 butyric acid methyl ester ≥99%](/deepweb/assets/sigmaaldrich/product/structures/359/221/d990c746-0960-4c69-bf76-fe09b193824d/640/d990c746-0960-4c69-bf76-fe09b193824d.png)