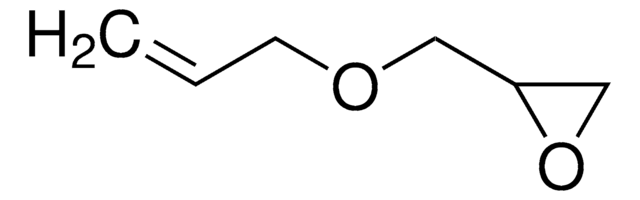

8.00609

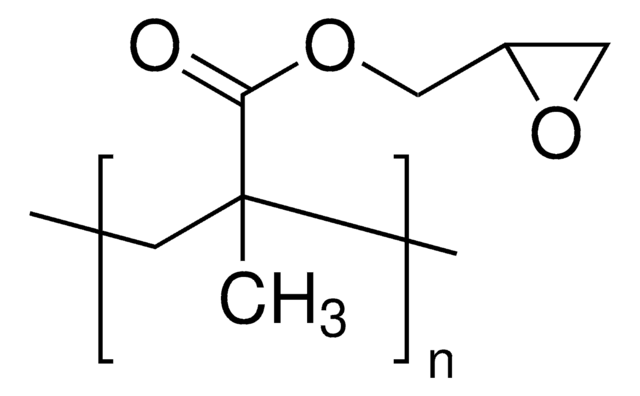

2,3-Epoxypropyl methacrylate

Technipur®, for synthesis

Sinônimo(s):

Glycidyl methacrylate, 2-((Methacryloxy)methyl)oxirane, 2,3-Epoxypropyl methacrylate, Methacrylic acid 2,3-epoxypropyl ester

About This Item

Produtos recomendados

grau

for synthesis

synthesis grade

Nível de qualidade

pressão de vapor

4.2 hPa ( 25 °C)

índice de refração

n20/D 1.449 (lit.)

p.e.

189 °C (lit.)

pf

<-60 °C

densidade

1.042 g/mL at 25 °C (lit.)

1.07 g/cm3 at 25 °C

cadeia de caracteres SMILES

CC(=C)C(=O)OCC1CO1

InChI

1S/C7H10O3/c1-5(2)7(8)10-4-6-3-9-6/h6H,1,3-4H2,2H3

chave InChI

VOZRXNHHFUQHIL-UHFFFAOYSA-N

Procurando produtos similares? Visita Guia de comparação de produtos

Descrição geral

Aplicação

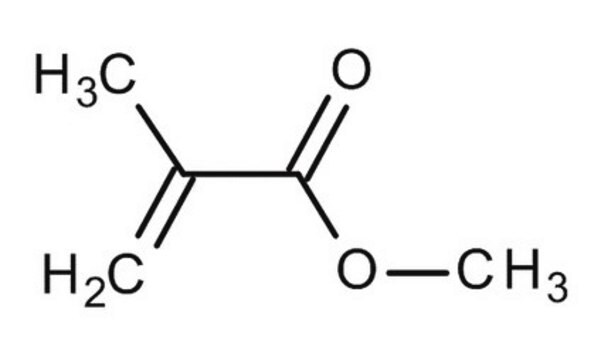

It is also used to prepare poly(n-butyl methacrylate-co-glycidyl methacrylate) copolymers, which find applications in adhesives, surface coatings, and electrical devices in various polymeric industries. The presence of epoxy groups and flexible butyl groups in epoxy resin-modified copolymers increases its mechanical properties, impact strength, and fracture elongation.

Informações legais

Palavra indicadora

Danger

Frases de perigo

Declarações de precaução

Classificações de perigo

Acute Tox. 3 Dermal - Acute Tox. 4 Oral - Carc. 1B - Eye Dam. 1 - Muta. 2 - Repr. 1B - Skin Corr. 1C - Skin Sens. 1 - STOT RE 1 - STOT SE 3

Órgãos-alvo

Respiratory system

Código de classe de armazenamento

6.1C - Combustible, acute toxic Cat.3 / toxic compounds or compounds which causing chronic effects

Classe de risco de água (WGK)

WGK 3

Ponto de fulgor (°F)

168.8 °F - closed cup

Ponto de fulgor (°C)

76 °C - closed cup

Certificados de análise (COA)

Busque Certificados de análise (COA) digitando o Número do Lote do produto. Os números de lote e remessa podem ser encontrados no rótulo de um produto após a palavra “Lot” ou “Batch”.

Já possui este produto?

Encontre a documentação dos produtos que você adquiriu recentemente na biblioteca de documentos.

Nossa equipe de cientistas tem experiência em todas as áreas de pesquisa, incluindo Life Sciences, ciência de materiais, síntese química, cromatografia, química analítica e muitas outras.

Entre em contato com a assistência técnica