902497

Polymer dielectric grey for screen printing

Synonym(s):

D2070423P5, Dielectric ink, Dielectric paste

About This Item

Recommended Products

description

Coverage: 305 cm2 per g (using a 230 mesh stainless steel screen with 13 micron emulsion)

Solvent Resistance: THF − Attack

Solvent Resistance: Acetone − Attack

Solvent Resistance: DMAC − Attack

Solvent Resistance: DMF− Attack

Solvent Resistance: MEK − Full attack

form

paste

composition

Solid content, 50-55% (at 150 °C)

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

viscosity

12.0-16.0 Pa.s (Haake RS1 C20/2° TiL at 230 sec-1 at 25 °C)

greener alternative category

, Enabling

General description

Application

Features and Benefits

Preparation Note

Ink Screen Life: >3 hours

Screen Types: stainless steel, polyester mesh 156-325 tpi

- Typical Drying Conditions: Dry at 80 °C for 30 minutes, or 130 °C for 10-15 minutes in a box oven

- Suitable for Jet drying, infra-red and drying in high speed

- reel-to-reel

Substrate: polyester, PVC, polycarbonate, ceramic or alumina

Legal Information

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Eye Irrit. 2

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Flash Point(F)

191.3 °F

Flash Point(C)

88.5 °C

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

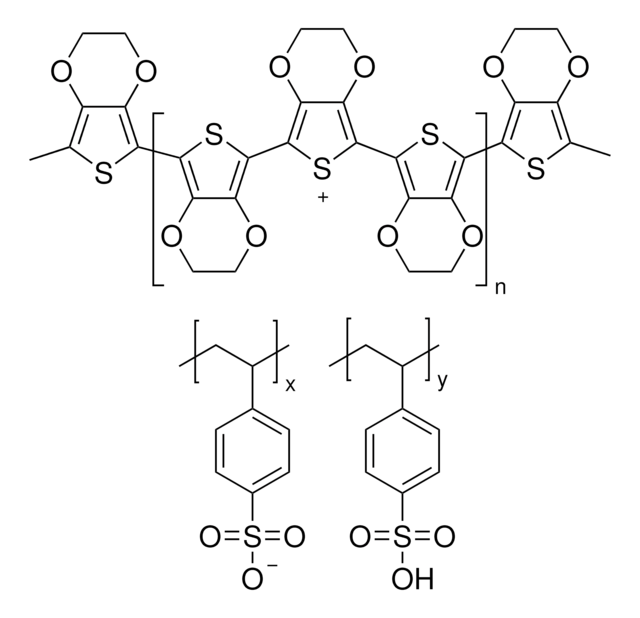

Articles

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service