901879

SunTronic® conductive silver ink for screen printing

Synonym(s):

Ag ink, SunTronic® AST6025, conductive ink, silver ink

About This Item

Recommended Products

description

Sheet resistivity: <0.010 Ω/sq/mil (150°C/10 min)

Solid content: 82-85% (120 °C)

Volume resistivity: <2.5x10-5 Ω.cm (150°C/30 min)

form

liquid

viscosity

45-55 Pa.s

storage temp.

2-8°C

General description

The ink exhibits high viscosity, low slumping, excellent conductivity and environmental stability, and adhesion to various substrates, including glass, various metals, PET, and transparent conductive films.

AST6025 is specifically suitable for printing of fine interconnects, printed RF antennae, and bus bars for touch panels.

Caution

Typical drying temperature may range from 120-200°C (248-392°F) depending on temperature tolerance of the substrate.Drying time may range from 2-30 minutes.Higher drying temperature and/or longer drying times will result in better electrical performance, adhesion and mechanical properties.

Optimum drying conditions should be established for particular equipment used by the customer.

AST6025 is supplied as ready-to-use ink. It should be stirred well prior to printing. AST6025 is suitable for use on hand, semi-automatic or fully automatic screen printing machines.

Typically, polyester or stainless screens with mesh count 325-430 threads/inch can be used depending on desired ink film thickness and resolution. For fine lines between 100 - 250 microns nominal line width, stainless screen mesh is preferred with mesh count between 325-400 threads/inch. For <100 microns line widths, 430 and higher stainless steel mesh counts are recommended.

Legal Information

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Aquatic Acute 1 - Aquatic Chronic 1 - Carc. 2 - Eye Dam. 1

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Flash Point(F)

212.0 °F

Flash Point(C)

100 °C

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

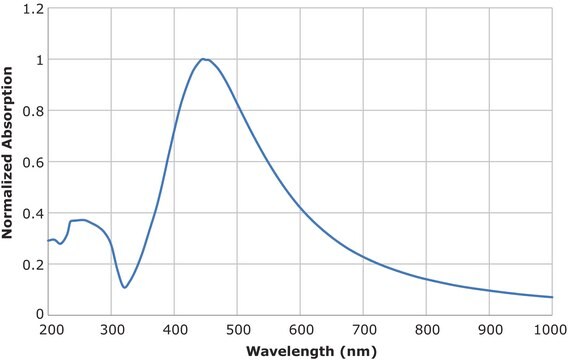

Customers Also Viewed

Articles

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service