Carboxen® Specialty Carbon Adsorbents

Advanced Materials for Industrial Purification and Separation

Specialty carbon adsorbents.

Our Specialty Carbon Adsorbents

Our specialty carbon adsorbents are engineered materials, made from pure synthetic polymers. Once made, the products are physically activated to avoid the use of chemicals in the process. This distinguishes our specialty carbon adsorbents from other available non-specific and low-tech carbon black and activated carbon adsorbents. The Carboxen® adsorbents are molecular sieve type adsorbents, ideal for industrial manufacturing processes.

Specialty carbon adsorbents find use in the challenging purifications and recovery applications. Their use in the petrochemical, chemical manufacturing, pharmaceutical, food and beverage, and environmental applications can be broken into 2 different types:

Purification - Includes the use of an interference removal technique to remove an impurity or impurities from a gas or a liquid stream for e.g. purification of industrial gases/solvents, effluent streams, or raw materials.

Recovery - Involves the use of a bind and elute technique to first capture a compound or compounds from a gas or liquid, followed by their recovery. Recovery can be done through thermal or solvent desorption. An example is the recovery of a synthesized compound from a reaction mixture.

Common applications:

- Adsorption and desorption of targeted analytes in water, air, soil, and serum

- Bulk-scale purification of gas and liquid streams

- Recovery of synthesized compounds from reaction mixtures

- Catalyst support in chemical reactions

Advantages of specialty carbon adsorbents

Why using a synthetic, high-engineered carbon matters?

Figure 1.Spherical particle showing different types of pores.

Key Features

The surface chemistry of our specialty carbon adsorbents is tailored for the specific target analytes. Although each of the existing products have their own performance advantage based on their characteristics, the products can be customized to meet specific customer requirements.

Products are designed with:

- Variable surface chemistry e.g. pH ranging from 2.5 up to 10.5

- Spherical shape to allow easy flow and consistent pressure during purification

- Customizable pore structure

- Non-porous or multi-porous to serve a specific purpose

- Macro-porous to enhance adsorption of large molecules

- Tapered pore sizing (from macro- to meso- to micro-), to increase thermodynamic and kinetic efficiency

- Thermal, radiation, & pH stability

- Attrition resistance

- Regeneration capabilities

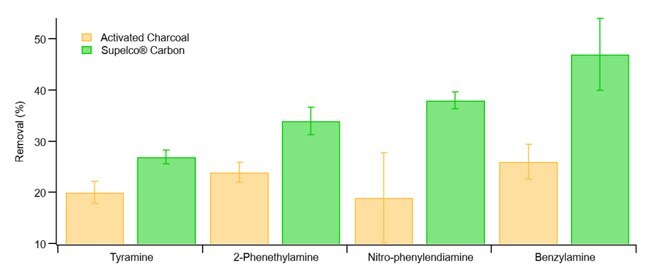

Our synthetic customized carbons outperform activated charcoal

Adsorption of basic compounds using Supelco® acidic carbons

Comparison of percentage removal efficiency for activated charcoal vs. synthetic customized carbons

Synthetic Carbon Product Properties

Ready-to-order synthetic carbon products

Carbon Adsorbent Sampler Kits

Choosing the right adsorbent or combination of adsorbents can be a challenge. Let us help you in selecting the appropriate adsorbent based on your specific application. We offer a convenient sampler kit, allowing a cost-effective evaluation of all scalable Carboxen® specialty carbon adsorbents.

Customization and Scale

If you do not find an adsorbent that meets your needs, let us know the matrix you work with (describe the gas or liquid), what you want to remove, and if you want to recover it afterwards. Our R&D group will investigate whether an existing adsorbent is appropriate or if a new adsorbent need to be developed. To inquire about a custom specialty carbon adsorbent, please contact our carbon experts.

These Carboxen® Carbon adsorbents are scalable, meaning ton quantities of these adsorbents in 20/40, 20/45, or 30/45 mesh can be produced.

To continue reading please sign in or create an account.

Don't Have An Account?