Universal Hydrophilic Syringe Filters: Millex® Hydrophilic PTFE

Polytetrafluoroethylene (PTFE) is widely used in membrane filters due to its high chemical resistance and low protein binding. However, the native hydrophobicity of unmodified PTFE restricts its use to the filtration of organic solvents and solutions. To overcome these limitations, several surface modification strategies have been adopted to produce hydrophilic PTFE membranes for use in the filtration of both aqueous and organic solutions.

As part of our comprehensive filtration offering, Millex® hydrophilic PTFE syringe filters offer many advantages including:

- Filtration of aqueous and organic solutions

- Wettable with water – no need to prewet with alcohols

- Broad chemical compatibility

- Accurate pore size

Wettability of Millex® Hydrophilic PTFE Membranes

Wettability refers to the ability of a liquid to remain in contact with a solid surface. In liquid filtration, the membrane must be wettable with the fluid being filtered to avoid resistance, which can lead to back pressure and an increased risk of membrane failure. Based upon the chemical properties of the membrane surface and the surface energy of the polymer, membrane wettability is characterized by the wetting angle.

As a perfluorinated polymer, polytetrafluoroethylene is highly hydrophobic. To overcome these native properties, hydrophilic coatings can be applied to allow hydrophilic PTFE membranes to wet spontaneously with water (Figure 1). The addition of the hydrophilic coating allows hydrophilic PTFE membranes to be used for the filtration of organic and aqueous solutions – eliminating the need for multiple filter types in the lab. During the coating process, hydrophilic PTFE membranes are also washed additional times, which further reduces residual extractable impurities present in the membrane.

Figure 1. Wetting of hydrophilic and hydrophobic PTFE membranes. A drop of water was added to each PTFE membrane, hydrophilic (left) and hydrophobic (right). The hydrophilic membrane wets spontaneously, while the water droplet sits on the hydrophobic surface.

Chemical Compatibility of Millex® Hydrophilic PTFE Syringe Filters

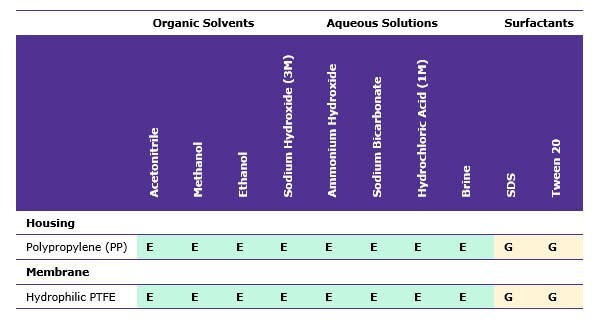

Millex® hydrophilic PTFE syringe filters feature a polypropylene housing and a PTFE membrane, providing broad chemical compatibility regardless of your application. The table below shows solvents and solutions commonly used with Millex® hydrophilic PTFE syringe filters – find our complete chemical compatibility list at

Figure. Solvents and solutions commonly used with Millex®

Low Analyte Binding of Millex® Hydrophilic PTFE Syringe Filters

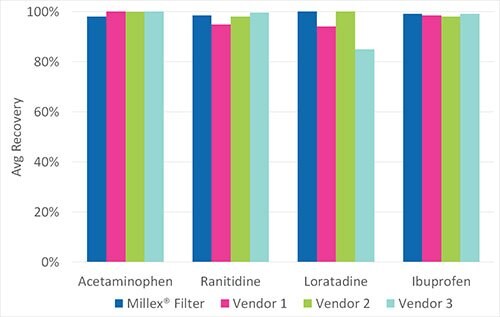

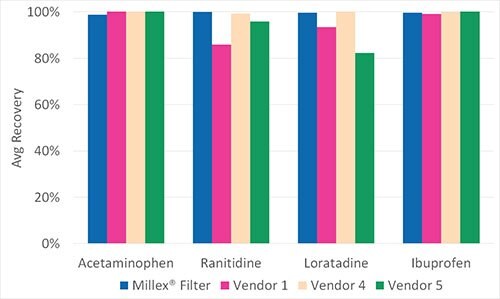

Analyte retention by syringe filters can skew the accuracy of results in analytical applications. Solutions with four different small molecule analytes were filtered using both 0.45 μm (Figure 2) and 0.2 μm (Figure 3) Millex® hydrophilic PTFE syringe filters. Retention results were compared to equivalent filters from other vendors. Millex® hydrophilic PTFE syringe filters boast low analyte retention, with ≥90% recovery of small molecules – matching or exceeding the performance of other equivalent filters.

Figure 2.Comparison of small molecule retention of 0.45 μm hydrophilic PTFE syringe filters from different vendors.

Figure 3. Comparison of small molecule retention of 0.2 μm hydrophilic PTFE syringe filters from different vendor.

Accurate Pore Size of Millex® Hydrophilic PTFE Syringe Filters

Pore size provides an indication of the average pore diameter and can be related to the membrane’s ability to filter out particles of a certain size. While there are no industry standard tests for determining pore size, pore size accuracy is critical for many applications and in preventing analyte binding.

Pore size of Millex® syringe filters is verified by bubble point testing. The bubble point test uses an inverse relationship between bubble point and pore size to determine the maximum pore size of a membrane. We performed a particle retention test to confirm the pore size accuracy of Millex® hydrophilic PTFE syringe filters, in comparison to equivalent filters from other vendors (Figure 4).

Figure 4. Comparison of particle retention for 0.45 μm hydrophilic PTFE syringe filters from different vendors

Solutions containing a known concentration of either 0.24 μm or 0.5 μm particles were filtered using 0.45 μm hydrophilic PTFE syringe filters and particle concentration in the final filtrate was measured to determine the average particle retention for each filter. Based upon the 0.45 μm pore size rating, 0.24 μm particles should be able to pass through the filter into the filtrate, while 0.5 μm particles should be retained. As shown in Figure 4, all syringe filters from other vendors showed ≥80% retention of 0.24 μm particles, despite their 0.45 μm pore size rating. This suggests the actual membrane pore size is much smaller than the rating provided by the vendor, which can lead to slower flow rates, increased pressure, and issues with downstream HPLC analysis. The accurate pore size of Millex® syringe filters ensure the better filtration results every time.

To continue reading please sign in or create an account.

Don't Have An Account?