181315

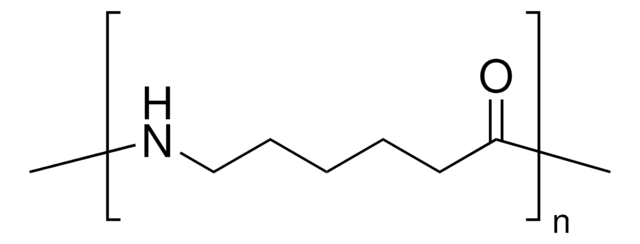

Polyacrylonitrile

average Mv 150,000

Synonym(s):

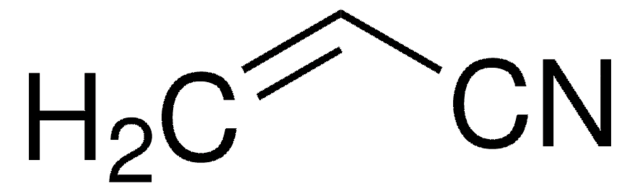

Vinyl cyanide

About This Item

Recommended Products

mol wt

average Mv 150,000

Quality Level

refractive index

n20/D 1.514

transition temp

Tm 317 °C

Tg 85 °C

density

1.184 g/mL at 25 °C (lit.)

SMILES string

C=CC#N

InChI

1S/C3H3N/c1-2-3-4/h2H,1H2

InChI key

NLHHRLWOUZZQLW-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

Storage Class

11 - Combustible Solids

wgk_germany

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

ppe

Eyeshields, Gloves, type N95 (US)

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

In this article, we discuss issues critical to successful application of the electrospinning technique, including control of individual nanofibers to form secondary structures and assembly of nanofibers into 3D architectures.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service