추천 제품

Grade

analytical standard

Quality Level

vapor pressure

1 mmHg ( 102 °C)

분석

≥97.5% (GC)

97.5-102.5% (T)

유통기한

limited shelf life, expiry date on the label

기술

HPLC: suitable

gas chromatography (GC): suitable

bp

245-246 °C (lit.)

mp

30-33 °C (lit.)

density

1.134 g/mL at 25 °C (lit.)

응용 분야

cleaning products

cosmetics

flavors and fragrances

food and beverages

personal care

형식

neat

SMILES string

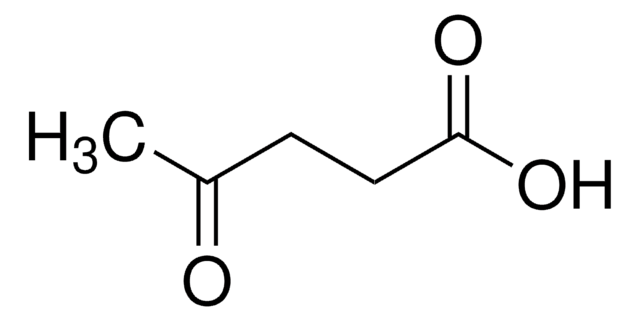

CC(=O)CCC(O)=O

InChI

1S/C5H8O3/c1-4(6)2-3-5(7)8/h2-3H2,1H3,(H,7,8)

InChI key

JOOXCMJARBKPKM-UHFFFAOYSA-N

유사한 제품을 찾으십니까? 방문 제품 비교 안내

일반 설명

Levulinic acid (LA), is a biogenic product of hexose acid hydrolysis, produced from renewable or bio-based resources. LA is reported to react with a variety of compounds to result in products, which are widely used in pharmaceuticals, personal care products, electronics, plasticizers, antifouling compounds, fuels, solvents, polymers, anti-freeze agents, batteries, coatings, biologically active materials, corrosion inhibitors, adsorbents, etc. LA is also employed as a chemical intermediate in the production of biodegradable polymers, fuel extenders, herbicides, flavors, antibiotics and useful 5-carbon compounds.

This substance is listed on the positive list of the EU regulation 10/2011 for plastics intended to come into contact with food. Find all available reference materials for compounds listed in 10/2011 here

애플리케이션

Levulinic acid may be used as an analytical reference standard

for the quantification of the analyte in the following:

for the quantification of the analyte in the following:

- Soy sauce using liquid chromatography coupled to mass spectrometry (LC–MS).

- Liquid food samples using gas chromatography with flame ionization detection (GC-FID).

신호어

Danger

유해 및 위험 성명서

Hazard Classifications

Acute Tox. 4 Oral - Eye Dam. 1 - Skin Sens. 1

Storage Class Code

13 - Non Combustible Solids

WGK

WGK 2

Flash Point (°F)

208.4 °F - closed cup

Flash Point (°C)

98 °C - closed cup

이미 열람한 고객

Kan Liu et al.

Bioresource technology, 176, 88-97 (2014-12-03)

Eastern redcedar is an invasive softwood species in Oklahoma and across grasslands in the Central Plains of the United States and potential feedstock for butanol production. Butanol has higher energy content than ethanol and can be upgraded to jet and

Johan O Westman et al.

Applied and environmental microbiology, 80(22), 6908-6918 (2014-08-31)

Yeast has long been considered the microorganism of choice for second-generation bioethanol production due to its fermentative capacity and ethanol tolerance. However, tolerance toward inhibitors derived from lignocellulosic materials is still an issue. Flocculating yeast strains often perform relatively well

Anupam Bera et al.

International journal of biological macromolecules, 72, 487-494 (2014-09-07)

Production of polyhydroxyalkanoates (PHAs) from Jatropha biodiesel residues, namely crude glycerol and oil cake hydrolysate, has been reported previously. Halomonas hydrothermalis (MTCC accession no. 5445; NCBI Genbank accession no. GU938192), a wild marine strain, was used in the bio-synthesis. The

F Monlau et al.

Bioresource technology, 187, 379-386 (2015-04-13)

The robust supramolecular structure of biomass often requires severe pretreatments conditions to produce soluble sugars. Nonetheless, these processes generate some inhibitory compounds (i.e. furans compounds and aliphatic acids) deriving mainly from sugars degradation. To avoid the inhibition of the biological

Rui Xie et al.

Bioresource technology, 186, 106-113 (2015-03-31)

Carbonyl compounds generated in biomass pretreatment hinder the biochemical conversion of biomass hydrolysates to biofuels. A novel approach of detoxifying hydrolysates with amino acids for ethanol production was developed. Among the 20 amino acids assessed for their detoxification efficiency and

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.