추천 제품

설명

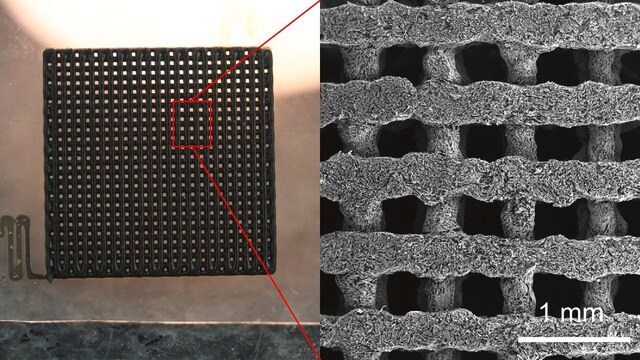

Printing methods compatible with: Direct-Ink-Writing 3D printing

Quality Level

형태

paste

환경친화적 대안 제품 특성

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

농도

70 wt. % (Yttria stabilized zirconia)

색상

white

입자 크기

120 nm

점도

2-25 Pa.s (25 °C at shear rate of 100 s-1)

환경친화적 대안 카테고리

저장 온도

2-8°C

일반 설명

We are committed to bringing you Greener Alternative Products, which adhere to one or more of The 12 Principles of Green Chemistry. This product has been enhanced for energy efficiency. Click here for more information.

애플리케이션

This product can be used in material extrusion 3D printing technique.

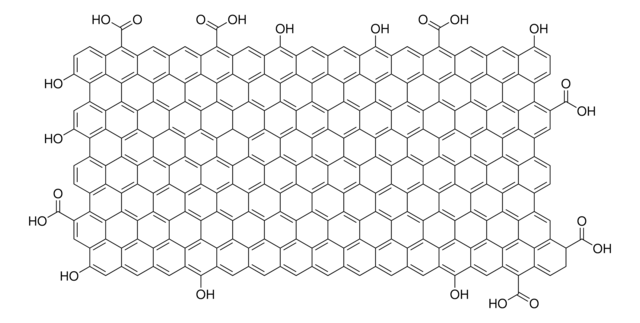

This product is a thixotropic ink based on yttria stabilized zirconia (YSZ) nanoparticles. It is suitable for various direct ink write (aka robocasting) printing technologies . Our YSZ ink has also been validated for stereolithography (SLA) 3D printing. The ink offers a stable dispersion of YSZ, high viscosity, good printability, and long shelf life. Annealed patterns provide excellent chemical resistance and high surface area. The ink is suitable for applications such as membranes, catalysis, separators and reactors.

주의사항

Handeling tips:

- Store in an airtight sealed container in refrigerator.

- Avoid exposure to heat.

- Add the thermal initiator (product No.479896) to 0.3wt% of the total 3Y-ZrO2/PEGDA ink mass, and mix well before usage.

제조 메모

Step-by-Step procedure for ink mixing and loading into syringe is in attached file.

Direct-Ink-Writing (DIW) Notes:

Post Processing of DIW printed parts:

Ramp to 300°C @ 1°C/min. Hold for 4 hours.

Ramp to 400°C @ 1°C/min. Hold for 2 hours.

Ramp to 800°C @ 2°C/min. Hold for 4 hours.

Ramp to 1090°C @ 2°C/min. Hold for 15 hours.

Ramp down to 50°C @ 2°C/min.

Direct-Ink-Writing (DIW) Notes:

- Syringe Nozzle sizes ranging from 250 μm − 800 μm can be used.

- Initial pressure for DIW printing ranges from 12-18 psi, depending on nozzle diameter used.

Post Processing of DIW printed parts:

- Curing @ 110°C for 12-16 hours.

- Sintering using the following sequence:

Ramp to 300°C @ 1°C/min. Hold for 4 hours.

Ramp to 400°C @ 1°C/min. Hold for 2 hours.

Ramp to 800°C @ 2°C/min. Hold for 4 hours.

Ramp to 1090°C @ 2°C/min. Hold for 15 hours.

Ramp down to 50°C @ 2°C/min.

저장 및 안정성

Tighly seal remaining ink, and store in 2-8° C fridge.

신호어

Danger

유해 및 위험 성명서

Hazard Classifications

Eye Dam. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

표적 기관

Respiratory system

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

가장 최신 버전 중 하나를 선택하세요:

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.