추천 제품

설명

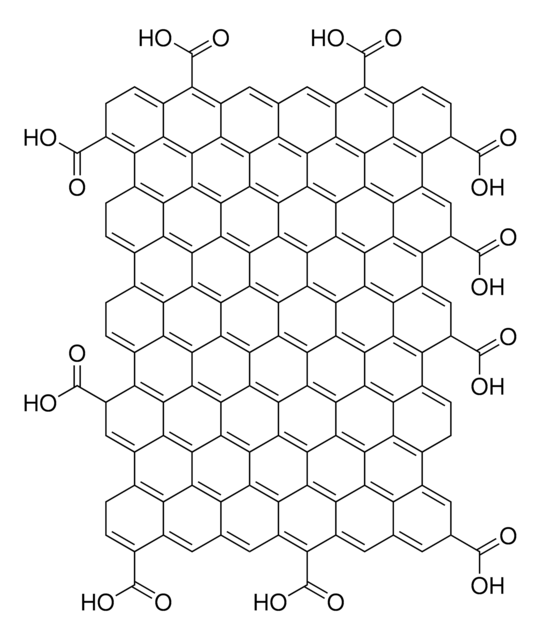

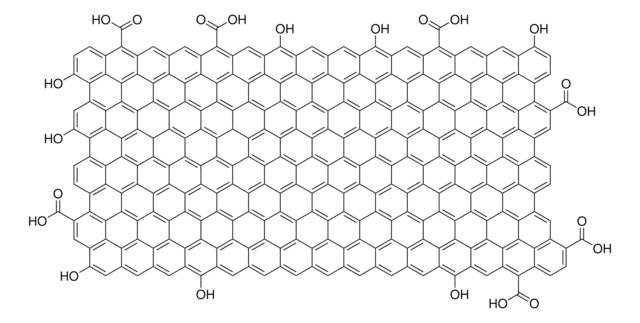

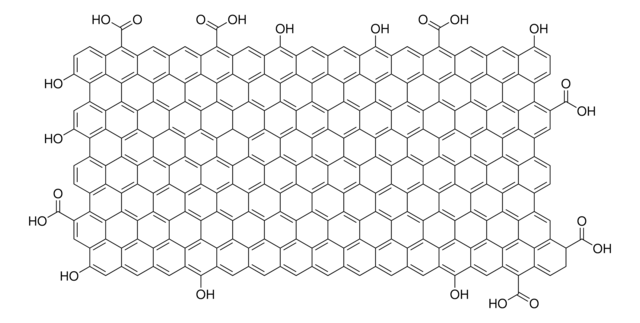

Graphene oxide sheet size: 300-800 nm lateral size

Number of layer for graphene oxide: single layer

Quality Level

형태

liquid

특징

avg. no. of layers 1

환경친화적 대안 제품 특성

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

농도

40 mg/mL (Graphene oxide aquous ink)

점도

100-210 Pa.s (25 °C at shear rate of 10 s-1)

환경친화적 대안 카테고리

, Enabling

저장 온도

2-8°C

일반 설명

We are committed to bringing you Greener Alternative Products, which adhere to one or more of The 12 Principles of Green Chemistry. This product has been enhanced for energy efficiency. Click here for more information.

애플리케이션

This product can be used in material extrusion 3D printing technique.

This product is a thixotropic ink based on graphene oxide (GO) nanosheets. It is suitable for various direct ink write (aka robocasting) printing technologies. The ink offers a stable dispersion of GO, high viscosity, good printability, and long shelf life. Freeze-dried and annealed patterns provide low electrical resistivity and high surface area. The ink is suitable for applications such as batteries, supercapacitors, electrocatalysis, etc.

제조 메모

Before Printing:

Bring the ink to room temeprature, best to mix the ink in a planetary mixer before usage.

Printing:

Recommended 3D printing nozzle diameter size is 400 micron.

Post printing:

After 3D printing, this ink can be directly freeze-dried in liquid nitrogen and vacuum to obtain free- standing graphene oxide aerogel.

This ink can also be processed by adding gelling agents to enable a covalent bond established between the graphene oxide sheets. Gelation agents such as ammonium carbonate, ammonium hydroxide, resorcinol formaldehyde have all been reported to be sufficient. After gelation, the wet GO gels printed parts are washed in acetone to remove water from the pores. Supercritical CO2 can then be used to dry the GO gels.

Curing:

Parts that are printed with gelling agent can be cured in sealed glass vials at 85 °C.

The dried aerogels are generally reduced to graphene aerogels by thermal treatment at 1050 °C under inert atmosphere. Other chemical reduction methods include hydrazine reduction, dried aerogels can also be reduced using hydroiodic acid, followed by washing in ethanol, water and then freeze drying.

Bring the ink to room temeprature, best to mix the ink in a planetary mixer before usage.

Printing:

Recommended 3D printing nozzle diameter size is 400 micron.

Post printing:

After 3D printing, this ink can be directly freeze-dried in liquid nitrogen and vacuum to obtain free- standing graphene oxide aerogel.

This ink can also be processed by adding gelling agents to enable a covalent bond established between the graphene oxide sheets. Gelation agents such as ammonium carbonate, ammonium hydroxide, resorcinol formaldehyde have all been reported to be sufficient. After gelation, the wet GO gels printed parts are washed in acetone to remove water from the pores. Supercritical CO2 can then be used to dry the GO gels.

Curing:

Parts that are printed with gelling agent can be cured in sealed glass vials at 85 °C.

The dried aerogels are generally reduced to graphene aerogels by thermal treatment at 1050 °C under inert atmosphere. Other chemical reduction methods include hydrazine reduction, dried aerogels can also be reduced using hydroiodic acid, followed by washing in ethanol, water and then freeze drying.

저장 및 안정성

Tighly seal remaining ink, and store in 2-8 °C fridge.

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

가장 최신 버전 중 하나를 선택하세요:

Toward Macroscale, Isotropic Carbons with Graphene-Sheet-Like Electrical and Mechanical Properties.

Worsley M A, et al.

Advances in Functional Materials, 24(27), 4259-4264 (2014)

Versatile mechanically strong and highly conductive chemically converted graphene aerogels..

Liu Y, et al.

Carbon, 125, 352-359 (2017)

Bin Yao et al.

Advanced materials (Deerfield Beach, Fla.), 32(8), e1906652-e1906652 (2020-01-18)

The performance of pseudocapacitive electrodes at fast charging rates are typically limited by the slow kinetics of Faradaic reactions and sluggish ion diffusion in the bulk structure. This is particularly problematic for thick electrodes and electrodes highly loaded with active

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.