おすすめの製品

詳細

Microfludic chip x1

類似した製品をお探しですか? 訪問 製品比較ガイド

アプリケーション

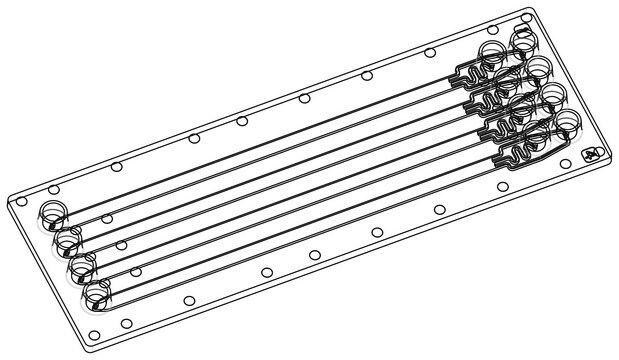

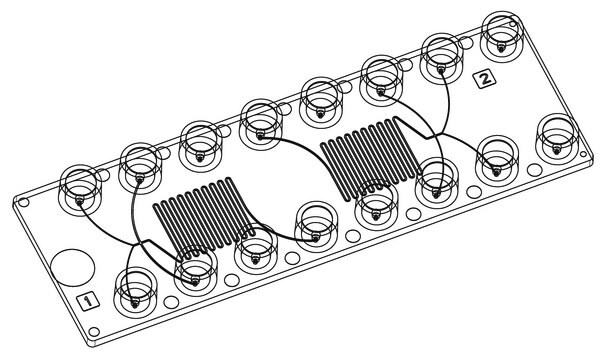

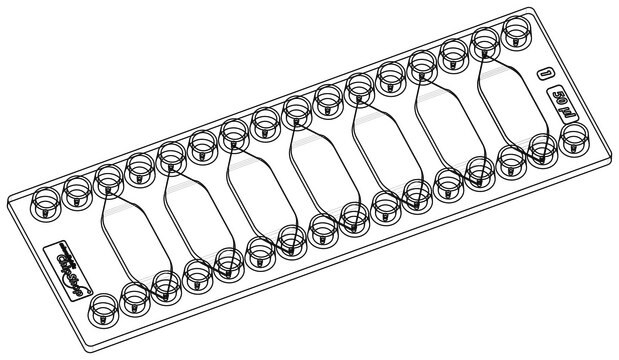

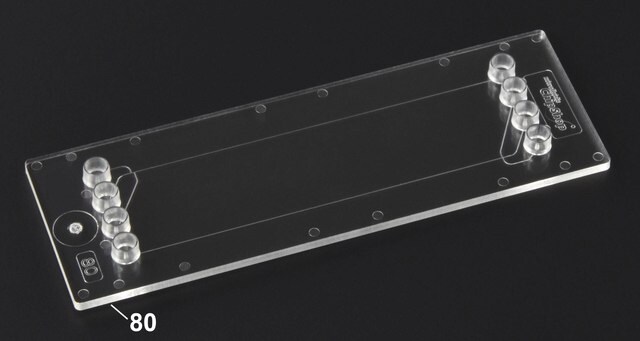

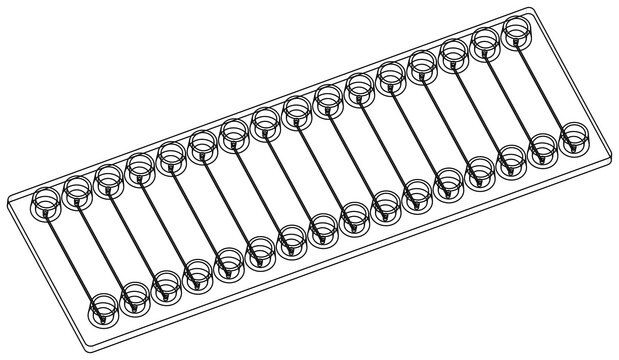

The Pillar Chip Fluidic 261 PMMA microfluidic chip uses integrated pillars to serve various needs.

特徴および利点

The integrated pillar structures can be used to

- Maintain particles at a certain area

- Allow for self-filling of devices via capillary forces

- Increase surface area

- Have a sieving effect

- Functionalize particle surfaces

構成

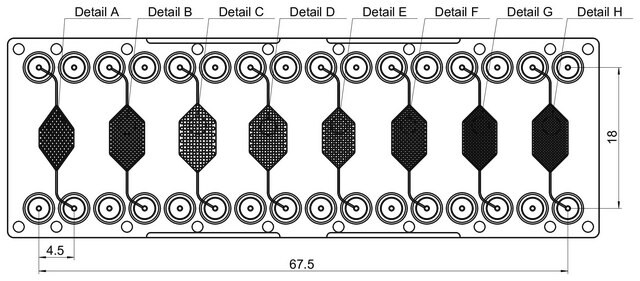

Chip Properties:

2: 150 μm/ 400 μm/ 150 μm

3: 200 μm/ 500 μm/ 200 μm

4: 250 μm/ 500 μm/ 200 μm

5: 300 μm/ 700 μm/ 250 μm

6: 350 μm/ 800 μm/ 250 μm

7: 150 μm/ 500 μm/ 300 μm

8: 150 μm/ 500-700 μm/ 300μm

- Mini Luer Interface

- Material: Poly(methyl methacrylate) (PMMA)

- Pillars have a demolding angle of 10°

- Pillar Number: Diameter/Distance/Depth

2: 150 μm/ 400 μm/ 150 μm

3: 200 μm/ 500 μm/ 200 μm

4: 250 μm/ 500 μm/ 200 μm

5: 300 μm/ 700 μm/ 250 μm

6: 350 μm/ 800 μm/ 250 μm

7: 150 μm/ 500 μm/ 300 μm

8: 150 μm/ 500-700 μm/ 300μm

最新バージョンのいずれかを選択してください:

Sharma T Sanjay et al.

Advanced drug delivery reviews, 128, 3-28 (2017-09-19)

Conventional systematically-administered drugs distribute evenly throughout the body, get degraded and excreted rapidly while crossing many biological barriers, leaving minimum amounts of the drugs at pathological sites. Controlled drug delivery aims to deliver drugs to the target sites at desired

Dongfei Liu et al.

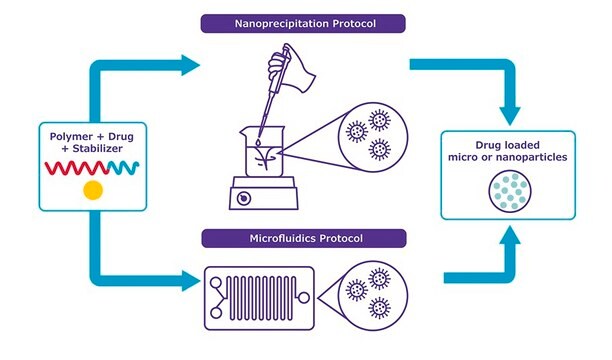

Lab on a chip, 17(11), 1856-1883 (2017-05-10)

The microfluidic technique has brought unique opportunities toward the full control over the production processes for drug delivery carriers, owing to the miniaturisation of the fluidic environment. In comparison to the conventional batch methods, the microfluidic setup provides a range

ライフサイエンス、有機合成、材料科学、クロマトグラフィー、分析など、あらゆる分野の研究に経験のあるメンバーがおります。.

製品に関するお問い合わせはこちら(テクニカルサービス)