677396

Magnesium aluminate, spinel

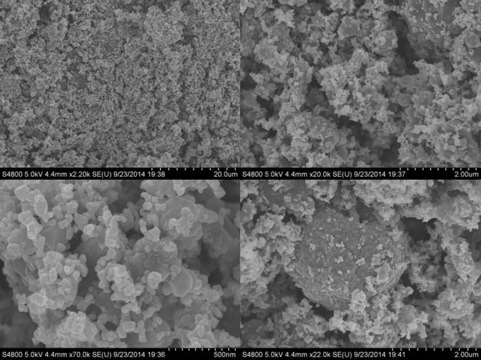

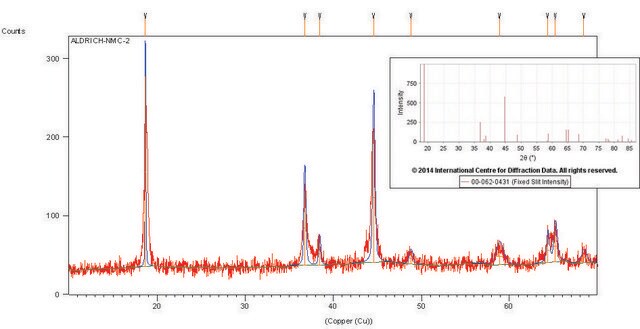

nanopowder, <50 nm particle size (BET)

Sinonimo/i:

Magnesium aluminate

About This Item

Prodotti consigliati

Stato

nanopowder

Livello qualitativo

Impiego in reazioni chimiche

reagent type: catalyst

core: magnesium

Area superficiale

>30 m2/g

Dimensione particelle

<50 nm (BET)

Punto di fusione

2130 °C (lit.)

Densità

3.64 g/mL at 25 °C (lit.)

Stringa SMILE

[Mg++].[O-][Al]=O.[O-][Al]=O

InChI

1S/2Al.Mg.4O/q;;+2;;;2*-1

VPBIQXABTCDMAU-UHFFFAOYSA-N

Cerchi prodotti simili? Visita Guida al confronto tra prodotti

Applicazioni

- A Review on Processing Polycrystalline Magnesium Aluminate Spinel (MgAl2O4): This review discusses various sintering techniques, material properties, and machinability of polycrystalline magnesium aluminate spinel, highlighting its optical transparency and mechanical properties (Z Shi et al., 2020).

- Effect of Structure and Composition of Non-Stoichiometry Magnesium Aluminate Spinel on Water Adsorption: This study examines how the structure and composition of magnesium aluminate spinel affect its water adsorption capabilities, focusing on the interaction with gases at different spinel compositions (Y Mordekovitz et al., 2020).

- Spectroscopic Study of Ordering in Non-Stoichiometric Magnesium Aluminate Spinel: The paper explores the ordering within non-stoichiometric magnesium aluminate spinel and its impact on material properties (V Erukhimovitch et al., 2015).

- Transparent Polycrystalline Magnesium Aluminate Spinel Fabricated by Spark Plasma Sintering: This research presents the fabrication of transparent polycrystalline magnesium aluminate spinel using spark plasma sintering, analyzing its mechanical and optical properties (M Sokol et al., 2018).

- A Comparative Study on the Effect of Different Additives on the Formation and Densification of Magnesium Aluminate Spinel: Investigates the effects of various additives on the formation and densification of magnesium aluminate spinel, providing insights into the synthesis and optimization of this ceramic material (SK Mohan et al., 2016).

Note legali

Avvertenze

Warning

Indicazioni di pericolo

Consigli di prudenza

Classi di pericolo

Eye Irrit. 2 - Skin Irrit. 2 - STOT SE 3

Organi bersaglio

Respiratory system

Codice della classe di stoccaggio

13 - Non Combustible Solids

Classe di pericolosità dell'acqua (WGK)

WGK 3

Punto d’infiammabilità (°F)

Not applicable

Punto d’infiammabilità (°C)

Not applicable

Dispositivi di protezione individuale

Eyeshields, Gloves, type N95 (US)

Scegli una delle versioni più recenti:

Possiedi già questo prodotto?

I documenti relativi ai prodotti acquistati recentemente sono disponibili nell’Archivio dei documenti.

I clienti hanno visto anche

Il team dei nostri ricercatori vanta grande esperienza in tutte le aree della ricerca quali Life Science, scienza dei materiali, sintesi chimica, cromatografia, discipline analitiche, ecc..

Contatta l'Assistenza Tecnica.