725544

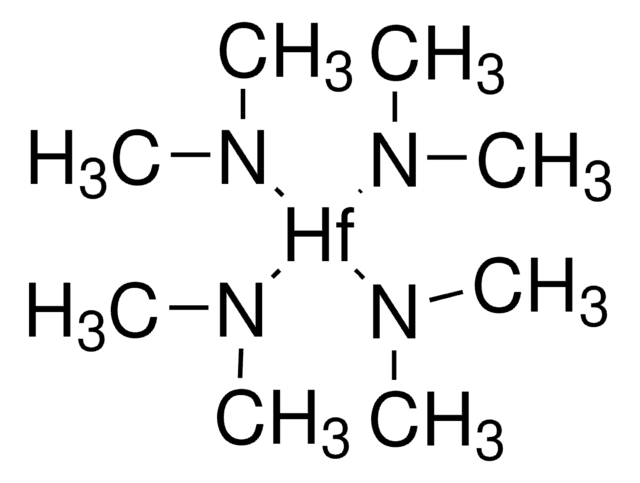

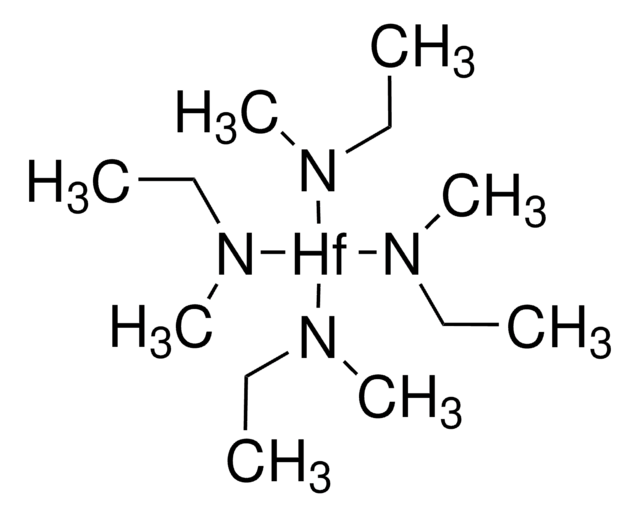

Tetrakis(ethylmethylamido)hafnium(IV)

packaged for use in deposition systems

Synonyme(s) :

TEMAH, Tetrakis(ethylmethylamino)hafnium(IV)

About This Item

Produits recommandés

Niveau de qualité

Forme

liquid

Pertinence de la réaction

core: hafnium

reagent type: catalyst

pb

78 °C/0.01 mmHg (lit.)

Pf

<-50 °C

Densité

1.324 g/mL at 25 °C (lit.)

Température de stockage

2-8°C

Chaîne SMILES

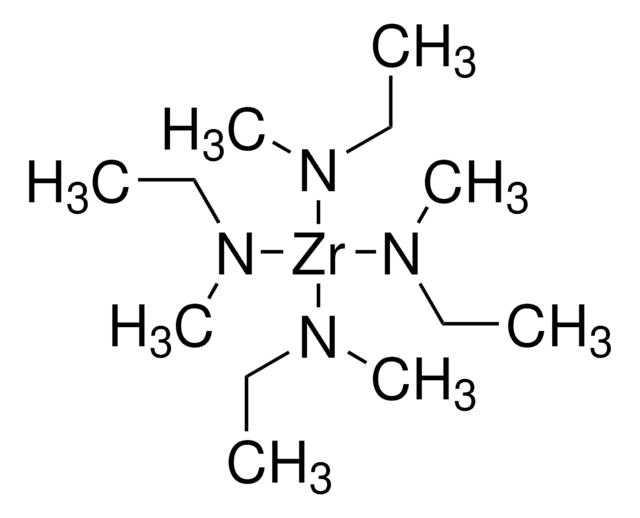

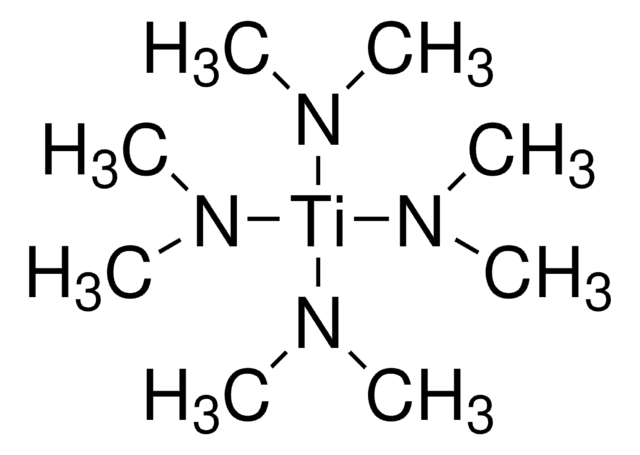

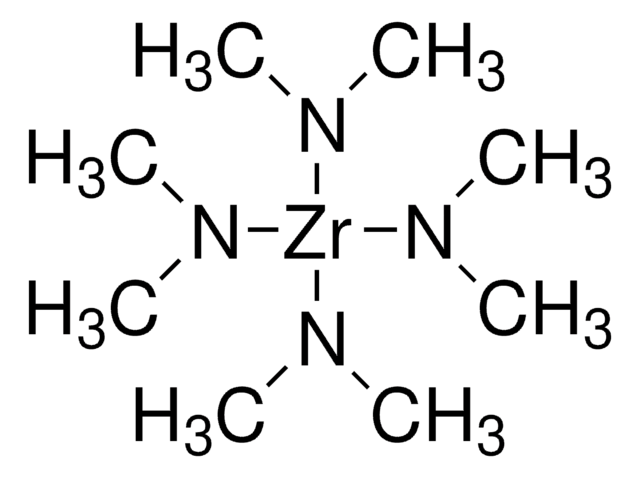

CCN(C)[Hf](N(C)CC)(N(C)CC)N(C)CC

InChI

1S/4C3H8N.Hf/c4*1-3-4-2;/h4*3H2,1-2H3;/q4*-1;+4

Clé InChI

NPEOKFBCHNGLJD-UHFFFAOYSA-N

Vous recherchez des produits similaires ? Visite Guide de comparaison des produits

Description générale

Application

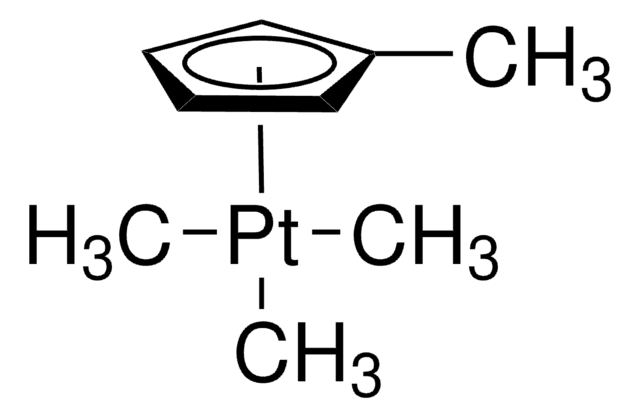

TEMAH is well-suited for ALD because its adsorption is self-limiting on a number of substrates including glass, indium-tin oxide(ITO), Si(100), and two-dimensional materials like MoS2. TEMAH also conveniently reacts with either water or ozone as the oxygen-source in the ALD process.

Caractéristiques et avantages

- Steel cylinder connected to 316 stainless steelball-valve

- 1/4 inch male Swagelok VCR connections

Mention d'avertissement

Danger

Mentions de danger

Classification des risques

Acute Tox. 4 Oral - Eye Dam. 1 - Flam. Liq. 2 - Skin Corr. 1B - STOT SE 3 - Water-react 1

Organes cibles

Respiratory system

Risques supp

Code de la classe de stockage

4.3 - Hazardous materials which set free flammable gases upon contact with water

Classe de danger pour l'eau (WGK)

WGK 3

Point d'éclair (°F)

51.8 °F - closed cup

Point d'éclair (°C)

11 °C - closed cup

Faites votre choix parmi les versions les plus récentes :

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

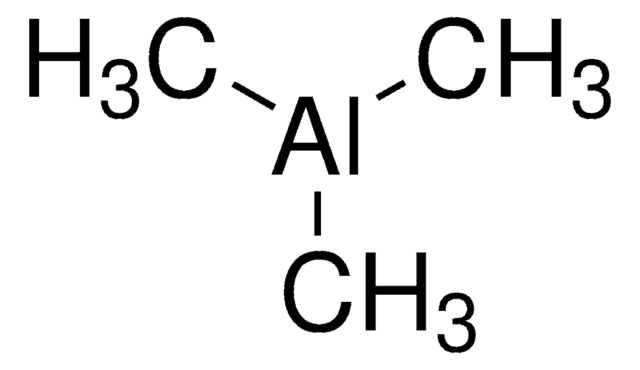

Les clients ont également consulté

Articles

Atomic Layer Deposition (ALD) is a coating technology that allows perfectly conformal deposition onto complex 3D surfaces. The reason for this uniform coating lies in the saturative chemisorption of sequential cycles of precursor vapors.

Nanocomposite Coatings with Tunable Properties Prepared by Atomic Layer Deposition

Thin film photovoltaic devices have become increasingly important in efficiently harnessing solar energy to meet consumer demand.

The properties of many devices are limited by the intrinsic properties of the materials that compose them.

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique