221007

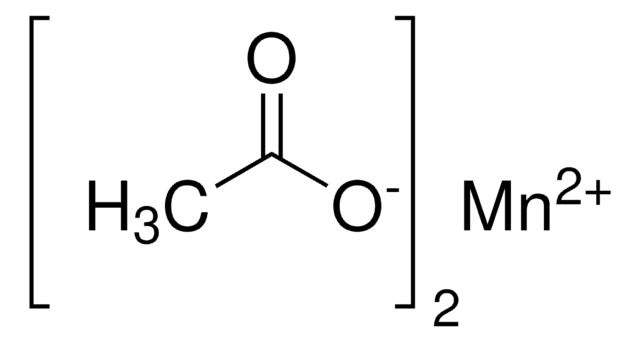

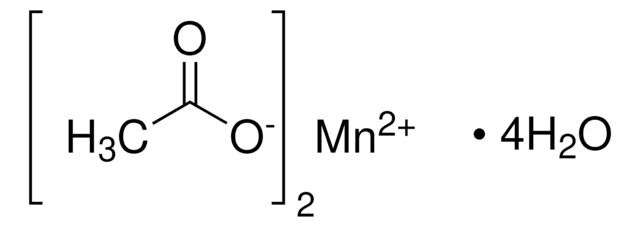

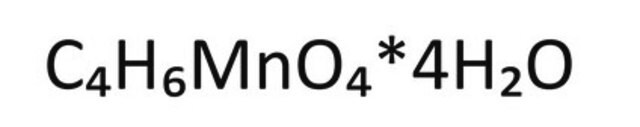

Manganese(II) acetate tetrahydrate

≥99%

Synonyme(s) :

Manganese Diacetate Tetrahydrate, Manganous acetate

About This Item

Produits recommandés

Pureté

≥99%

Forme

crystals

Pertinence de la réaction

core: manganese

Pf

>300 °C (lit.)

Densité

1.589 g/mL at 25 °C (lit.)

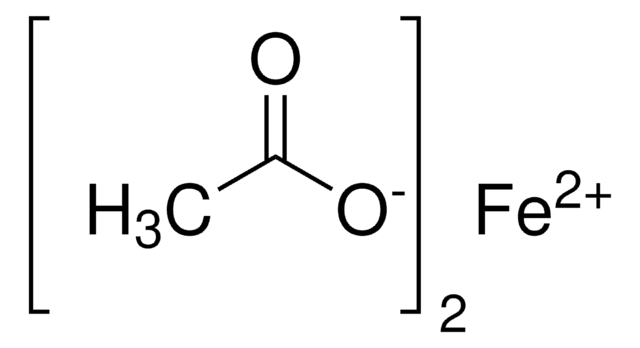

Chaîne SMILES

[H]O[H].[H]O[H].[H]O[H].[H]O[H].CC(=O)O[Mn]OC(C)=O

InChI

1S/2C2H4O2.Mn.4H2O/c2*1-2(3)4;;;;;/h2*1H3,(H,3,4);;4*1H2/q;;+2;;;;/p-2

Clé InChI

CESXSDZNZGSWSP-UHFFFAOYSA-L

Vous recherchez des produits similaires ? Visite Guide de comparaison des produits

Description générale

Application

- A starting material in the synthesis of manganese carboxylates, which are used to prepare manganese oxide thin films by chemical vapor deposition (CVD).

- A precursor in the synthesis of manganese-TiO2 composites by chemical vapor condensation (CVC).These composites are used in the oxidation of NO at low temperatures.

- A precursor in preparation of NCM (LiNi1/3Co1/3Mn1/3O2) powder applicable as cathode material in lithium-ion batteries.

- A starting material for the synthesis of LiMn2O4 (LMO) film on Au substrate by sol-gel method.

Mention d'avertissement

Warning

Mentions de danger

Conseils de prudence

Classification des risques

Aquatic Chronic 3 - STOT RE 2 Inhalation

Organes cibles

Brain

Code de la classe de stockage

11 - Combustible Solids

Classe de danger pour l'eau (WGK)

WGK 2

Point d'éclair (°F)

Not applicable

Point d'éclair (°C)

Not applicable

Équipement de protection individuelle

dust mask type N95 (US), Eyeshields, Gloves

Faites votre choix parmi les versions les plus récentes :

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

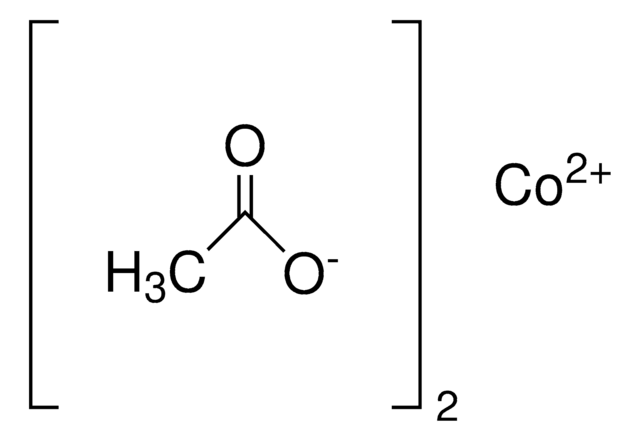

Les clients ont également consulté

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique