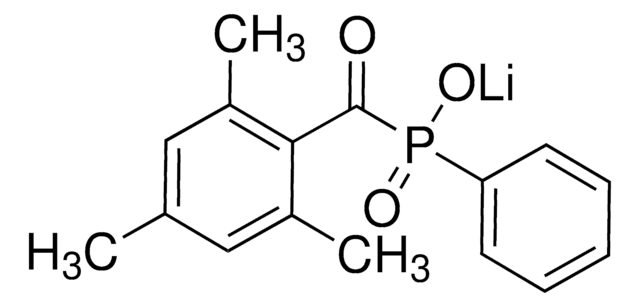

415952

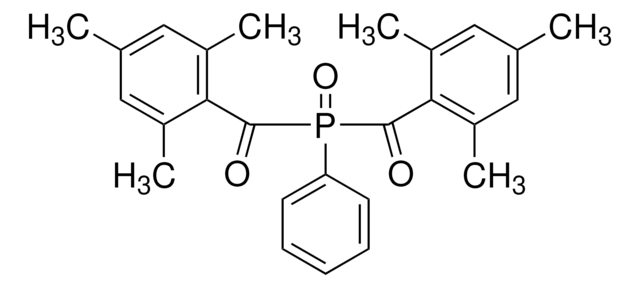

Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide

97%

Sinónimos:

(2,4,6-Trimethylbenzoyl)diphenylphosphine oxide, (Diphenylphosphoryl)(mesityl)methanone, 2,4,6-Trimethylbenzoylphenyl phosphinate

About This Item

Productos recomendados

Ensayo

97%

Formulario

powder

mp

88-92 °C (lit.)

cadena SMILES

Cc1cc(C)c(c(C)c1)C(=O)P(=O)(c2ccccc2)c3ccccc3

InChI

1S/C22H21O2P/c1-16-14-17(2)21(18(3)15-16)22(23)25(24,19-10-6-4-7-11-19)20-12-8-5-9-13-20/h4-15H,1-3H3

Clave InChI

VFHVQBAGLAREND-UHFFFAOYSA-N

Descripción general

Aplicación

Almacenamiento y estabilidad

Palabra de señalización

Warning

Frases de peligro

Consejos de prudencia

Clasificaciones de peligro

Aquatic Chronic 2 - Repr. 2 - Skin Sens. 1

Código de clase de almacenamiento

11 - Combustible Solids

Clase de riesgo para el agua (WGK)

WGK 2

Punto de inflamabilidad (°F)

Not applicable

Punto de inflamabilidad (°C)

Not applicable

Equipo de protección personal

Eyeshields, Gloves, type N95 (US)

Listados normativos

Los listados normativos se proporcionan para los productos químicos principalmente. Para los productos no químicos sólo se puede proporcionar información limitada. Si no hay ninguna entrada, significa que ninguno de los componentes está en la lista. Es obligación del usuario garantizar el uso seguro y legal del producto.

EU REACH SVHC Candidate List

Elija entre una de las versiones más recientes:

¿Ya tiene este producto?

Encuentre la documentación para los productos que ha comprado recientemente en la Biblioteca de documentos.

Los clientes también vieron

Artículos

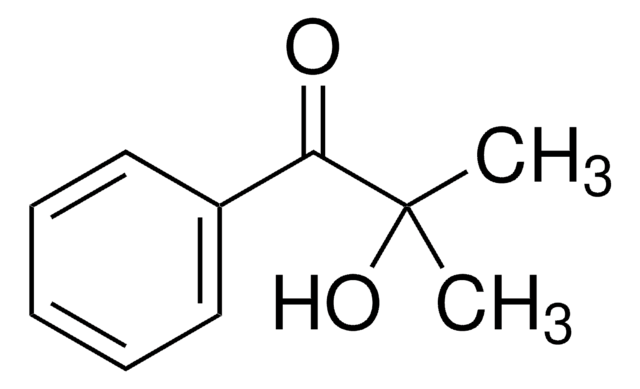

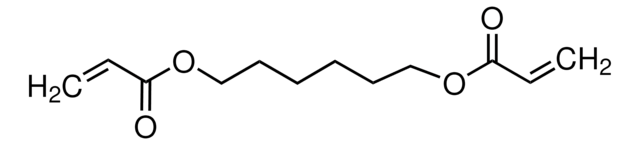

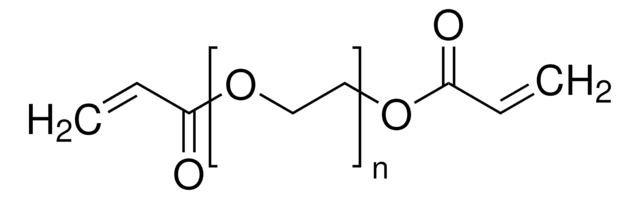

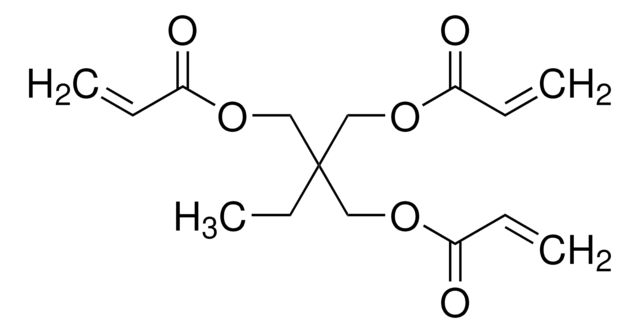

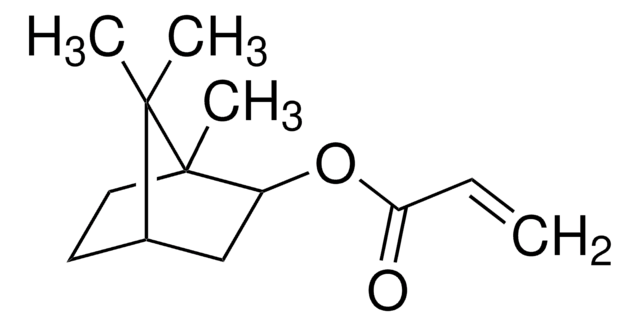

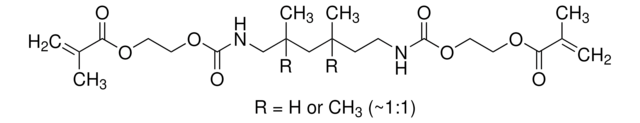

The manufacture of monomers for use in ophthalmic applications is driven by the need for higher purity, improved reliability of manufacturing supply, but ultimately by the need for the increased comfort, convenience, and safety of contact lens wearers. Daily wear contact lenses have the potential to fill this need for many customers; however, their widespread use is constrained by higher costs compared to weekly- or monthly-based lenses. New approaches that improve cost structure and result in higher quality raw materials are needed to help make contact lenses more affordable and accelerate growth of the contact lens market.

Nuestro equipo de científicos tiene experiencia en todas las áreas de investigación: Ciencias de la vida, Ciencia de los materiales, Síntesis química, Cromatografía, Analítica y muchas otras.

Póngase en contacto con el Servicio técnico