SAE0020

Cellulase, enzyme blend

Sinonimo/i:

Cellic CTec2

Autenticatiper visualizzare i prezzi riservati alla tua organizzazione & contrattuali

About This Item

Codice UNSPSC:

12352204

NACRES:

NA.54

Prodotti consigliati

Stato

aqueous solution

Livello qualitativo

Densità

~1.15 g/mL

Condizioni di spedizione

ambient

Temperatura di conservazione

2-8°C

Categorie correlate

Descrizione generale

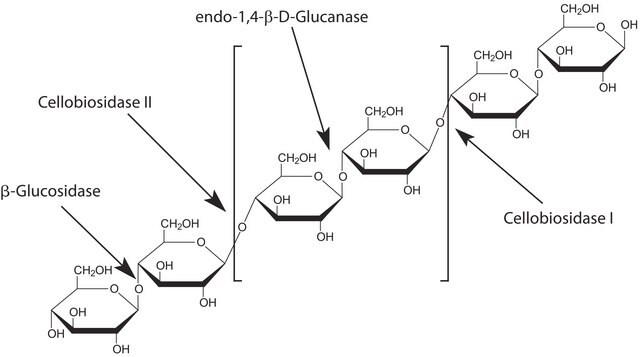

Cellulase is a member of glycoside hydrolase family and is produced by a number of cellulolytic microbes.

This product contains cellulases, ß-glucosidases, and hemicellulase, for the application of degrading cellulose to fermentable sugars. This product is effective on a wide variety of pre-treated lignocellulosic bimass materials, for converting the carbohydrates in these materials into simple sugars prior to fermentation, for application in biofuels research.

Applicazioni

Cellulase, enzyme blend has been used for the purpose of enzymatic hydrolysis.

Azioni biochim/fisiol

Cellulase is responsible for the breakdown of insoluble plant polymer cellulosic substrates into soluble sugars, mostly cellobiose and glucose. It specifically catalyzes the hydrolysis of β -1,4 glucosidic bonds in cellulose. Animals do not naturally possess the ability to digest cellulose, but do so with the help of gut microorganisms.

Note legali

A product of Novozyme Corp

Avvertenze

Danger

Indicazioni di pericolo

Consigli di prudenza

Classi di pericolo

Resp. Sens. 1

Codice della classe di stoccaggio

10 - Combustible liquids

Classe di pericolosità dell'acqua (WGK)

WGK 3

Scegli una delle versioni più recenti:

Possiedi già questo prodotto?

I documenti relativi ai prodotti acquistati recentemente sono disponibili nell’Archivio dei documenti.

I clienti hanno visto anche

Liwen He et al.

Bioresource technology, 289, 121693-121693 (2019-07-02)

The optimum condition of steam explosion pretreatment was screened for hippophae, and anaerobic calcium oxide (CaO) alkalization was further used to improve its enzymatic hydrolysis. Steam-exploded hippophae reached the lowest pH value (4.01) and the maximal hemicellulose removal (77.16%) at

A cellulase gene of termite origin.

Watanabe H, et al.

Nature, 394(6691), 330-330 (1998)

Model of acetic acid-affected growth and poly (3-hydroxybutyrate) production by Cupriavidus necator DSM 545.

Marudkla J, et al.

Journal of Biotechnology, 268, 12-20 (2018)

Liwen He et al.

Bioresource technology, 298, 122510-122510 (2019-12-15)

A better understanding of biomass usability during storage would offer basis for management decisions in production. High-moisture corn stover was ensiled with sulfuric acid (H2SO4, 0.3% and 0.6%) or sodium hydroxide (NaOH, 0.5% and 1.0%) and ensiling characteristics, lignocellulosic profile

Qiulu Chu et al.

Biotechnology for biofuels, 14(1), 136-136 (2021-06-14)

Ethanol organosolv (EOS) pretreatment is one of the most efficient methods for boosting biomass saccharification as it can achieve an efficient fractionation of three major constituents in lignocellulose. However, lignin repolymerization often occurs in acid EOS pretreatment, which impairs subsequent

Il team dei nostri ricercatori vanta grande esperienza in tutte le aree della ricerca quali Life Science, scienza dei materiali, sintesi chimica, cromatografia, discipline analitiche, ecc..

Contatta l'Assistenza Tecnica.