WHA7187114

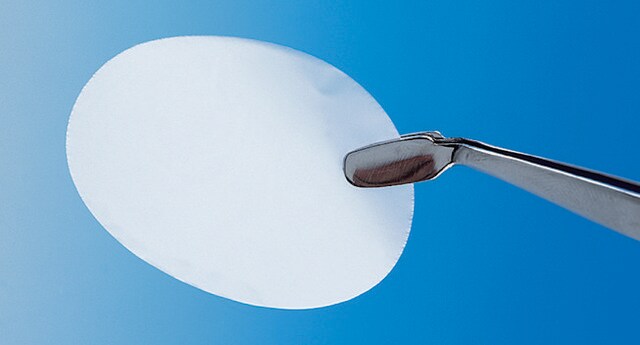

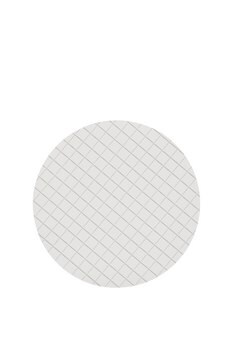

Whatman® mixed cellulose ester membrane filters

(white/black grid), pore size 0.2 μm, diam. 47 mm, sterile

Sinônimo(s):

Whatman® nitrocellulose membrane filters, Whatman filter, Z746053, membrane filters, syringe filter

About This Item

Produtos recomendados

Materiais

(white/black grid)

esterilidade

sterile

embalagem

pack of 100 ea

fabricante/nome comercial

Whatman 7187-114

Whatman Article No. 28420749 (US reference)

Diâmetro

47 mm

tamanho de poro

0.2 μm

Categorias relacionadas

Descrição geral

Recommended for the majority of routine applications, this membrane is manufactured under strictly controlled conditions. The user will benefit from the performance improvements which are now available in Whatman membrane filters, including very narrow pore size distribution and low levels of extractables.

Higher strength and flexibility:

Most membranes are inherently brittle and difficult to handle; it is not uncommon for filters to be damaged during loading into holders or while in use. Whatman mixed cellulose ester membrane filters have a noticeably improved flexibility and are made to tolerate abuse during handling, loading and autoclaving without sacrificing integrity. These membranes are among the strongest of their type available, as measured and compared by burst pressure tests.

Low extractable levels:

The level of extractables in membrane filters has become more important with advances in filtration or adsorption techniques. In particular, pharmaceutical, immunological and biomedical tissue culture and trace analysis applications can be adversely affected by high extractable levels. Whatman mixed cellulose ester membrane filters have a low level of extractables, generally below that of other membranes of a similar type.

Narrow pore size distribution:

One of the major features of Whatman membrane filters is the narrow distribution of pore sizes. The rated pore size of these membranes is closely controlled due to the advanced manufacturing and control system. Additionally, the batch-to-batch variation is minimized providing more consistent laboratory results.

Increased temperature stability:

Membrane filters are normally autoclaved at 121°C without loss of integrity. Cellulose nitrate membranes are supplied as circles, sheets or reels.

Reduced shrinkage:

Excessive shrinkage can cause problems during autoclaving and is often the cause of membranes tearing in their holders after autoclaving. It may also cause a reduction in flow rate and total throughput. Whatman membranes exhibit a low shrinkage during autoclaving.

Applications:

Sample preparation

Microbiological studies

Filtration of aqueous solutions

Higher strength and flexibility:

Most membranes are inherently brittle and difficult to handle; it is not uncommon for filters to be damaged during loading into holders or while in use. Whatman cellulose nitrate membrane filters have a noticeably improved flexibility and are made to tolerate abuse during handling, loading and autoclaving without sacrificing integrity. These membranes are among the strongest of their type available, as measured and compared by burst pressure tests.

Low extractable levels:

The level of extractables in membrane filters has become more important with advances in filtration or adsorption techniques. In particular, pharmaceutical, immunological and biomedical tissue culture and trace analysis applications can be adversely affected by high extractable levels. Whatman cellulose nitrate membrane filters have a low level of extractables, generally below that of other membranes of a similar type.

Narrow pore size distribution:

One of the major features of Whatman membrane filters is the narrow distribution of pore sizes. The rated pore size of these membranes is closely controlled due to the advanced manufacturing and control system. Additionally, the batch-to-batch variation is minimized providing more consistent laboratory results.

Increased temperature stability:

Membrane filters are normally autoclaved at 121°C without loss of integrity. Cellulose nitrate membranes are supplied as circles, sheets or reels.

Reduced shrinkage:

Excessive shrinkage can cause problems during autoclaving and is often the cause of membranes tearing in their holders after autoclaving. It may also cause a reduction in flow rate and total throughput. Whatman membranes exhibit a low shrinkage during autoclaving.

Applications:

- Sample preparation

- Microbiological studies

- Filtration of aqueous solutions

Outras notas

Informações legais

Palavra indicadora

Warning

Frases de perigo

Declarações de precaução

Código de classe de armazenamento

11 - Combustible Solids

Certificados de análise (COA)

Busque Certificados de análise (COA) digitando o Número do Lote do produto. Os números de lote e remessa podem ser encontrados no rótulo de um produto após a palavra “Lot” ou “Batch”.

Já possui este produto?

Encontre a documentação dos produtos que você adquiriu recentemente na biblioteca de documentos.

Nossa equipe de cientistas tem experiência em todas as áreas de pesquisa, incluindo Life Sciences, ciência de materiais, síntese química, cromatografia, química analítica e muitas outras.

Entre em contato com a assistência técnica