62285

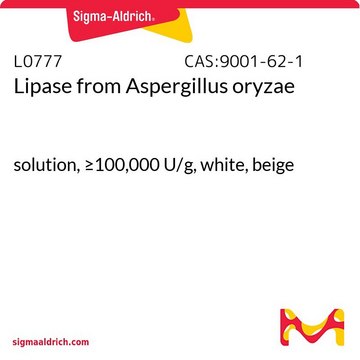

Lipase from Aspergillus oryzae

lyophilized, powder, white, ~50 U/mg

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

Recommended Products

form

powder

Quality Level

quality

lyophilized

specific activity

~50 U/mg

color

white

storage temp.

2-8°C

InChI

1S/C11H9N3O2.Na/c15-8-4-5-9(10(16)7-8)13-14-11-3-1-2-6-12-11;/h1-7,16H,(H,12,14);/q;+1/b13-9-;

InChI key

QWZUIMCIEOCSJF-CHHCPSLASA-N

Looking for similar products? Visit Product Comparison Guide

General description

Lipase is a carboxylesterase, which belongs to the α/β hydrolase fold family. It consists of a lid domain, hinge domain, and a catalytic triad Ser-His-Asp/Glu. Aspergillus oryzae lipase has a three-dimensional structure is an α/β hydrolase fold similar to that of the esterase enzyme.

Application

Lipase from Aspergillus oryzae has been used as a component of mixed enzyme solution to determine the viable cell numbers in the biofilms formed by Listeria monocytogenes strains.

Biochem/physiol Actions

Lipases are used industrially for the resolution of chiral compounds and the transesterification production of biodiesel.

Lipases catalyze the hydrolysis of triacylglycerols into glycerol and free fatty acids. Aspergillus oryzae lipase might be used in the production of biodiesel from waste cooking oil. It is used in the acetylation of cellulose and ochratoxin A degradation, and asymmetric organic synthesis. Lipase from Aspergillus oryzae is an industrial enzyme that has various uses in food, detergent, and pharmaceutical industries. It is useful in immobilization studies for 1,3-dioleoyl-2-palmitoylglycerol (OPO) synthesis.

Unit Definition

1 U corresponds to the amount of enzyme which liberates 1 μmol oleic acid per minute at pH 8.0 and 40°C (triolein, Cat. No. 62314 as substrate)

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Resp. Sens. 1

Storage Class Code

11 - Combustible Solids

WGK

WGK 1

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

dust mask type N95 (US), Eyeshields, Gloves

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Lipases: from production to applications

Melani N, et al.

Separation & Purification Reviews, 49(2), 143-158 (2020)

Youwen Pan et al.

Applied and environmental microbiology, 76(5), 1433-1441 (2010-01-06)

Biofilm formation by Listeria monocytogenes is generally associated with its persistence in the food-processing environment. Serotype 1/2a strains make up more than 50% of the total isolates recovered from food and the environment, while serotype 4b strains are most often

Haiying Cai et al.

PloS one, 10(7), e0133857-e0133857 (2015-07-29)

The enzymatic synthesis of 1,3-dioleoyl-2-palmitoylglycerol (OPO), one of the main components of human milk fats, has been hindered by the relatively high cost of sn-1,3-specific lipases and the deficiency in biocatalyst stability. The sn-1,3-specific lipase from Aspergillus oryzae (AOL) is

Hedwig Strohalm et al.

Journal of agricultural and food chemistry, 58(10), 6328-6333 (2010-04-27)

The preparation of ester enantiomers (acetates, butanoates, hexanoates and octanoates) of the secondary alcohols 2-pentanol, 2-heptanol and 2-nonanol via lipase-catalyzed kinetic resolutions was investigated. Conversion rates and stereochemical courses of esterification and hydrolysis reactions catalyzed by commercially available enzyme preparations

Guan-Chun Chen et al.

Biotechnology letters, 33(3), 525-529 (2010-11-04)

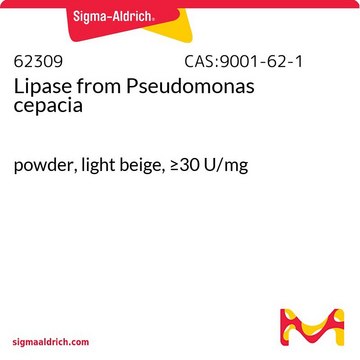

Triacylglycerol lipase from Pseudomonas cepacia and Fe(3)O(4) magnetic nanoparticles were encapsulated simultaneously within biomimetic silica through the catalysis of polyallylamine. The encapsulation efficiency reached 96% with an activity recovery of 51%. After 5 h at 37°C, the activities of the

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service