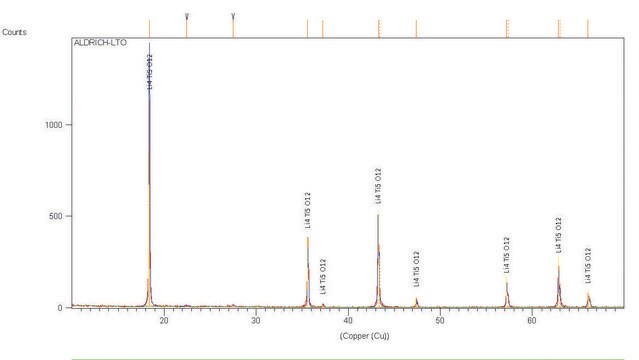

760994

Lithium nickel cobalt aluminium oxide

powder, <0.5 μm particle size, >98%

Synonym(s):

NCA

About This Item

Recommended Products

grade

battery grade

Assay

>98%

form

powder

mol wt

Mw 110.45 g/mol

composition

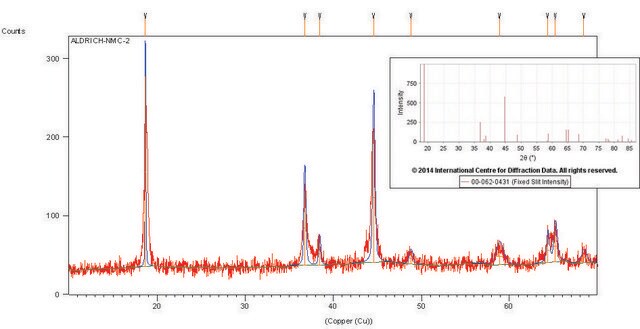

LiNi0.8Co0.15Al0.05O2

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

particle size

<0.5 μm

mp

>1000 °C (lit.)

density

4.45 g/cm3 (lit.)

application(s)

battery manufacturing

greener alternative category

General description

Application

Features and Benefits

Legal Information

related product

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Carc. 2 - Skin Sens. 1

Storage Class Code

13 - Non Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Professor Qiao’s laboratory lays out recent advances in conversion type lithium metal fluoride batteries. This review explores key concepts in developing electrochemically stable microstructures for wide Li-ion insertion channels.

The critical technical challenges associated with the commercialization of electric vehicle batteries include cost, performance, abuse tolerance, and lifespan.

Lithium-ion batteries (LIBs) have been widely adopted as the most promising portable energy source in electronic devices because of their high working voltage, high energy density, and good cyclic performance.

Due to the adverse impact of the continued use of fossil fuels on the earth’s environment and climate, researchers have been asked to develop new approaches for producing power using renewable sources like wind and solar energy

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service