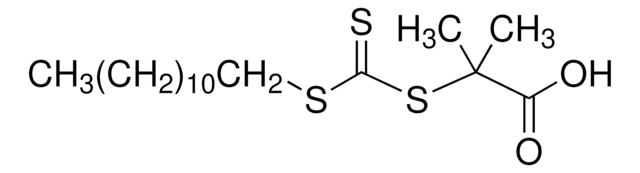

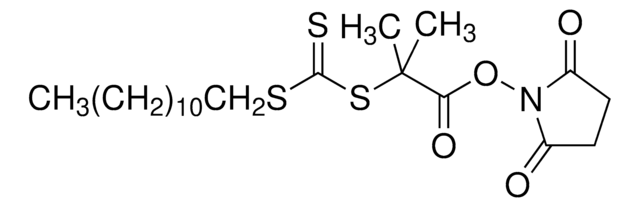

749133

2-(Dodecylthiocarbonothioylthio)propionic acid

97%

Synonym(s):

2-(Dodecylthiocarbonothioylthio)propanoic acid, 2-{[(Dodecylsulfanyl)carbonothioyl]sulfanyl}propanoic acid, DoPAT

About This Item

Recommended Products

Quality Level

Assay

97%

form

powder or crystals

mp

78-82 °C

storage temp.

2-8°C

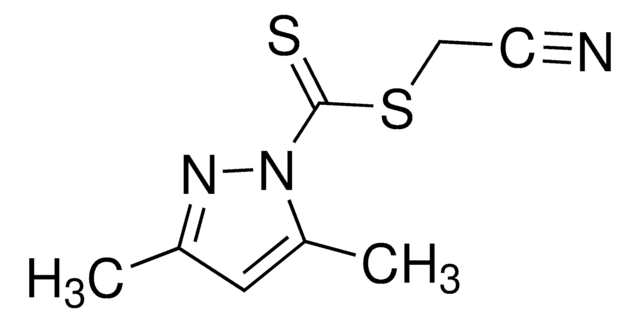

SMILES string

CCCCCCCCCCCCSC(=S)SC(C)C(O)=O

InChI

1S/C16H30O2S3/c1-3-4-5-6-7-8-9-10-11-12-13-20-16(19)21-14(2)15(17)18/h14H,3-13H2,1-2H3,(H,17,18)

InChI key

CFCFZJHCTNKHGJ-UHFFFAOYSA-N

Related Categories

General description

Application

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Aquatic Chronic 4 - Eye Irrit. 2 - Skin Irrit. 2 - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

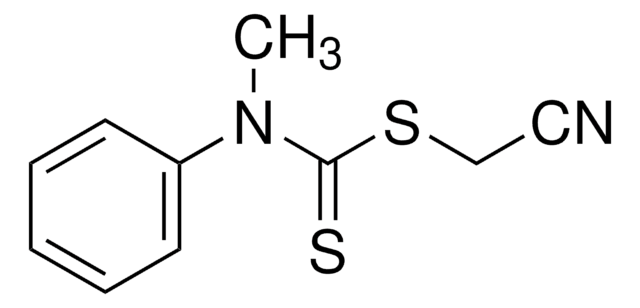

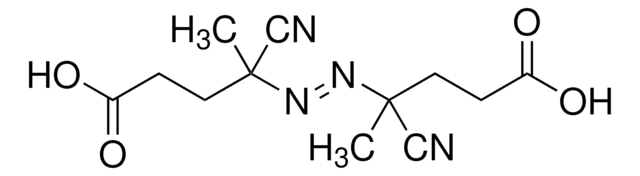

The supply of low cost, high purity and effective Reversible addition−fragmentation chain-transfer (RAFT) Agents is the essential element in the industrial implementation of RAFT polymerization technology.

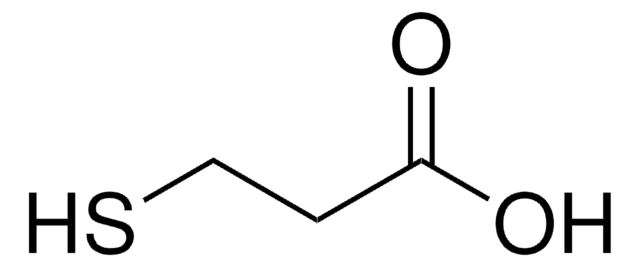

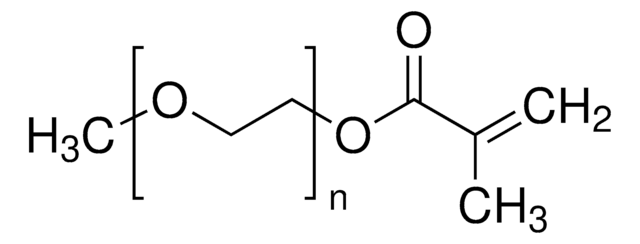

The modification of biomacromolecules, such as peptides and proteins, through the attachment of synthetic polymers has led to a new family of highly advanced biomaterials with enhanced properties.

We presents an article about a micro review of reversible addition/fragmentation chain transfer (RAFT) polymerization. RAFT (Reversible Addition/Fragmentation Chain Transfer) polymerization is a reversible deactivation radical polymerization (RDRP) and one of the more versatile methods for providing living characteristics to radical polymerization.

We presents an article about Copper(I)-mediated Living Radical Polymerization in the Presence of Pyridylmethanimine Ligands, and the emergence of living radical polymerization mediated by transition metal catalysts in 1995, which was a seminal piece of work in the field of synthetic polymer chemistry.

Protocols

Sigma-Aldrich presents an article about RAFT, or Reversible Addition/Fragmentation Chain Transfer, which is a form of living radical polymerization.

We presents an article featuring procedures that describe polymerization of methyl methacrylate and vinyl acetate homopolymers and a block copolymer as performed by researchers at CSIRO.

Sigma-Aldrich presents an article about the typical procedures for polymerizing via ATRP, which demonstrates that in the following two procedures describe two ATRP polymerization reactions as performed by Prof. Dave Hadddleton′s research group at the University of Warwick.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service

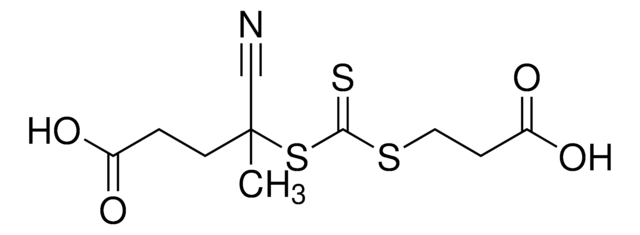

![2-[[(2-Carboxyethyl)sulfanylthiocarbonyl]-sulfanyl]propanoic acid](/deepweb/assets/sigmaaldrich/product/structures/427/606/b02310e2-102e-4324-b09d-e4c0de4fab2c/640/b02310e2-102e-4324-b09d-e4c0de4fab2c.png)

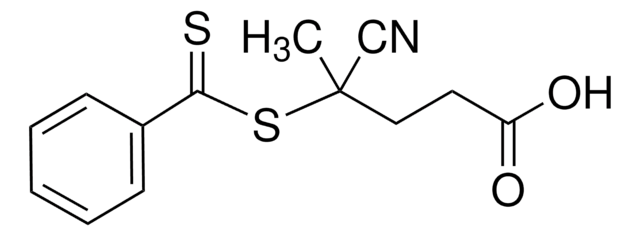

![4-Cyano-4-[(dodecylsulfanylthiocarbonyl)sulfanyl]pentanoic acid 97% (HPLC)](/deepweb/assets/sigmaaldrich/product/structures/204/925/30ae6ca0-5b0b-4963-a061-7e5e3d1a85af/640/30ae6ca0-5b0b-4963-a061-7e5e3d1a85af.png)

![4-Cyano-4-[(dodecylsulfanylthiocarbonyl)sulfanyl]pentanol](/deepweb/assets/sigmaaldrich/product/structures/839/520/64c23004-f340-460f-a379-8670a35d0433/640/64c23004-f340-460f-a379-8670a35d0433.png)