181528

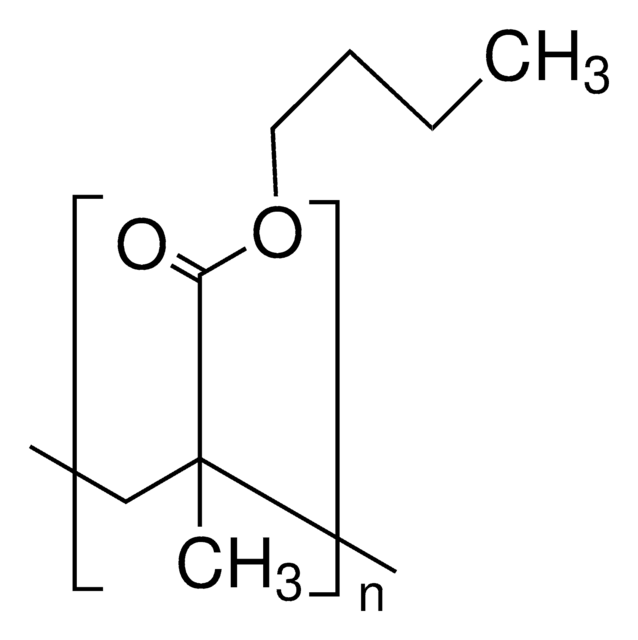

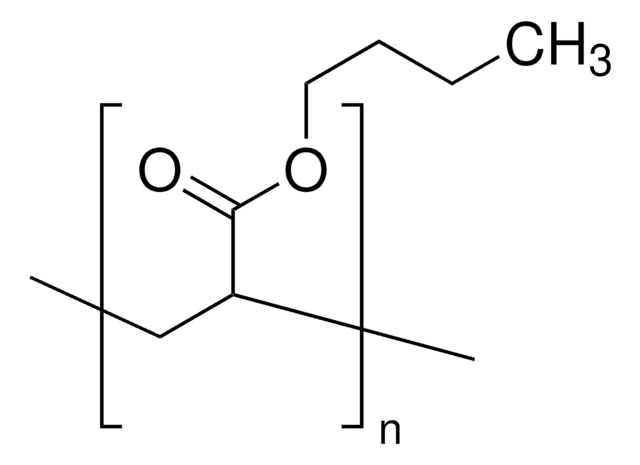

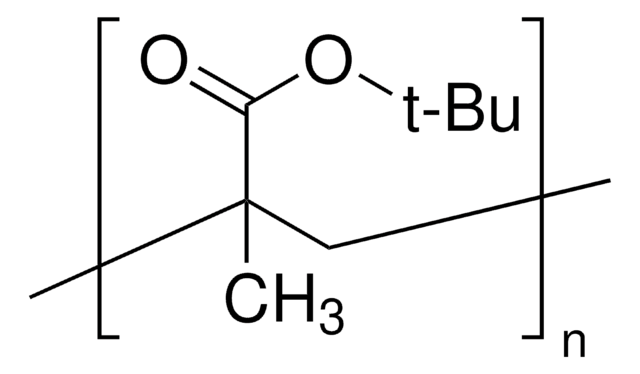

Poly(butyl methacrylate)

inherent viscosity 0.470-0.560 dL/g

Synonym(s):

PBMA

About This Item

Recommended Products

form

powder

mol wt

200000

refractive index

n20/D 1.483

inherent viscosity

0.470-0.560 dL/g

density

1.07 g/mL at 25 °C (lit.)

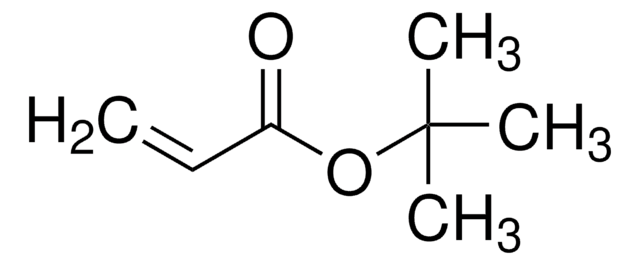

SMILES string

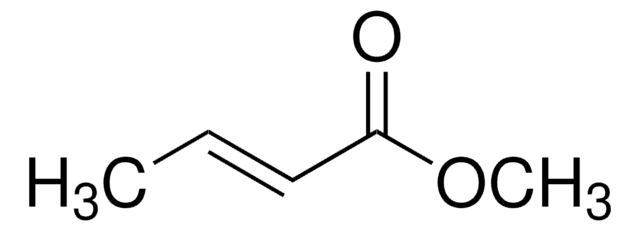

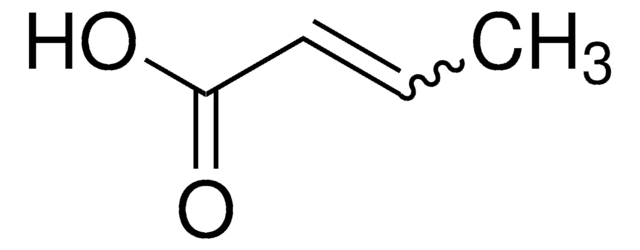

CCCCOC(=O)C(C)=C

InChI

1S/C8H14O2/c1-4-5-6-10-8(9)7(2)3/h2,4-6H2,1,3H3

InChI key

SOGAXMICEFXMKE-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

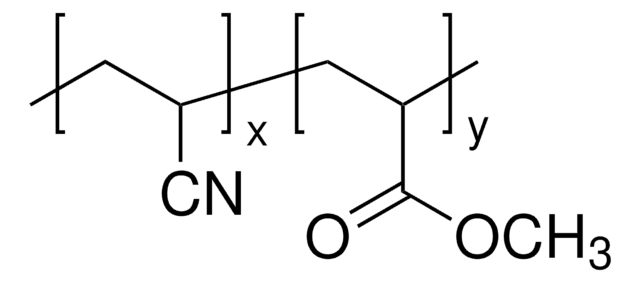

It can be used to prepare thermoresponsive microfibers with excellent mechanical properties. PBMA-containing microfibers can be used as temperature-modulated cell separation materials.

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Skin Sens. 1

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Self-assembled monolayers (SAMs) have attracted enormous interest for a wide variety of applications in micro- and nano-technology. In this article, we compare the benefits of three different classes of SAM systems (alkylthiolates on gold.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service