推薦產品

描述

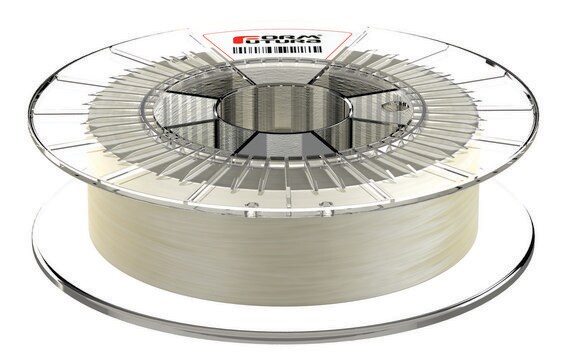

Filament diameter: 1.75 ± 0.05 mm

Filament roundness: ≥95%

Melt flow rate: 14-20 g/10 min

Melt temperature: ± 163 °C

Print temperature: ±180-205 °C

Specific gravity: 1.23 g/cc

Spool Hub Diameter: 52 mm

Spool Size (D x H): 200 mm x 55 mm

Viscat softening temperature: ± 60.2 °C

形狀

solid (filament)

顏色

colorless

InChI

1S/C2H4O/c1-2-3/h2-3H,1H2

InChI 密鑰

IMROMDMJAWUWLK-UHFFFAOYSA-N

尋找類似的產品? 前往 產品比較指南

一般說明

Polyvinyl alcohol (PVA) printing filament is a water-soluble support material for multi-extrusion 3D printing of complex architectures. PVA is widely used in traditional industries, such as textiles and papermaking, as well as a wide variety of coatings. This colorless, odorless, and high-quality filament extrudes between 180 to 205 °C and is suitable with all RepRap technology-based desktop 3D printers, such as MakerBot, Ultimaker, RepRap (Mendel, Huxley, Prusa), UP!, Solidoodle, Leapfrog, etc. PVA features good adhesion to PLA and nylon materials and is biodegradable in water with no hazardous by-products. While PVA is soluble in cold water, the dissolution process can be accelerated by using a continuously heated bath of warm water. When not in use, the filament should be stored at room temperature in dry conditions, such as in a sealed plastic bag or in a closed container with desiccant. Recommended initial printer settings can be found in the ′General Print Settings′ file.

應用

Due to its water-solubility and biocompatibility, polyvinyl alcohol (PVA) filaments are most commonly used as a sacrificial material in the formation of tissue engineering constructs with unique and complicated architectures. The use of this material allows for the printing of scaffolds with large overhangs, deep internal cavities, and/or intricate geometries. In addition to their use as sacrificial materials, PVA filaments have also been used to print novel oral drug delivery devices and tablets.

法律資訊

Product of Formfutura VOF

AquaSolve is a trademark of Formfutura VOF

儲存類別代碼

11 - Combustible Solids

水污染物質分類(WGK)

WGK 1

閃點(°F)

49.5 °F

閃點(°C)

9.7 °C

客戶也查看了

3D Printing of Medicines: Engineering Novel Oral Devices with Unique Design and Drug Release Characteristics.

Goyanes A, et al.

Molecular Pharmaceutics, 12(11), 4077-4084 (2015)

3D Printing Factors Important for the Fabrication of Polyvinylalcohol Filament-Based Tablets.

Tagami T, et al.

Biological & Pharmaceutical Bulletin, 40(3), 357-364 (2017)

Alice Melocchi et al.

International journal of pharmaceutics, 509(1-2), 255-263 (2016-05-25)

Fused deposition modeling (FDM) is a 3D printing technique based on the deposition of successive layers of thermoplastic materials following their softening/melting. Such a technique holds huge potential for the manufacturing of pharmaceutical products and is currently under extensive investigation.

Shuai Li et al.

ACS applied materials & interfaces, 8(38), 25096-25103 (2016-09-09)

Despite considerable advances in tissue engineering over the past two decades, solutions to some crucial problems remain elusive. Vascularization is one of the most important factors that greatly influence the function of scaffolds. Many research studies have focused on the

R Hernández-Córdova et al.

Journal of biomedical materials research. Part A, 104(8), 1912-1921 (2016-03-19)

Biomaterial scaffolds are a key part of cardiac tissue engineering therapies. The group has recently synthesized a novel polycaprolactone based polyurethane-urea copolymer that showed improved mechanical properties compared with its previously published counterparts. The aim of this study was to

我們的科學家團隊在所有研究領域都有豐富的經驗,包括生命科學、材料科學、化學合成、色譜、分析等.

聯絡技術服務