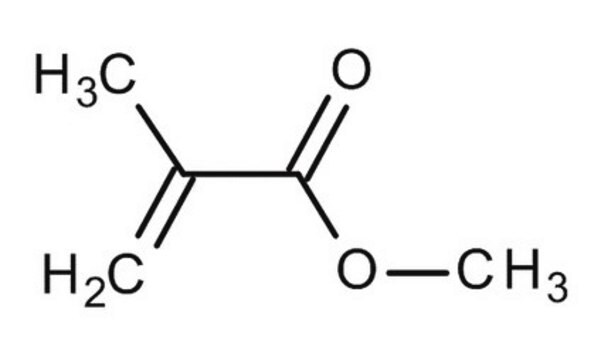

M55909

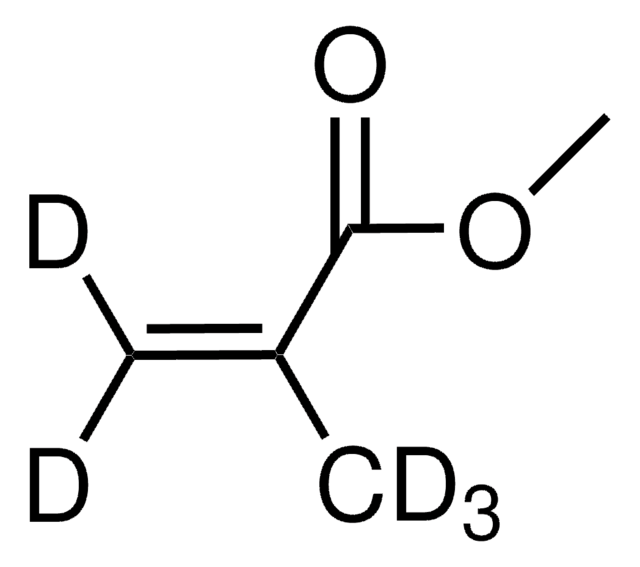

Methyl methacrylate

contains ≤30 ppm MEHQ as inhibitor, 99%

동의어(들):

Methacrylic acid methyl ester, Methyl 2-methylprop-2-enoate, Methyl 2-methylpropenoate

About This Item

추천 제품

vapor density

3.5 (vs air)

Quality Level

vapor pressure

29 mmHg ( 20 °C)

분석

99%

autoignition temp.

815 °F

포함

≤30 ppm MEHQ as inhibitor

expl. lim.

12.5 %

refractive index

n20/D 1.414 (lit.)

bp

100 °C (lit.)

mp

−48 °C (lit.)

density

0.936 g/mL at 25 °C (lit.)

저장 온도

2-8°C

SMILES string

COC(=O)C(C)=C

InChI

1S/C5H8O2/c1-4(2)5(6)7-3/h1H2,2-3H3

InChI key

VVQNEPGJFQJSBK-UHFFFAOYSA-N

유사한 제품을 찾으십니까? 방문 제품 비교 안내

일반 설명

애플리케이션

- Lanthanide-complex grafted poly(methyl methacrylate-co-maleic anhydride) copolymer. These luminescent polymers exhibit high thermal stability and can be used as luminous layers for optoelectronic devices.

- Poly (methyl methacrylate) (PMMA), is a common material used in the production of lenses for concentrating photovoltaic (CPV) modules.

- Polymethyl methacrylate, methyl methacrylate crosspolymer, and methyl methacrylate/glycol dimethacrylate crosspolymers. These polymers are used in cosmetic surgery, dentistry, and joint replacement.

- Poly (methyl methacrylate) (PMMA)-based personalized medical devices.

- Interpenetrating methyl methacrylate-based polymeric networks with enhanced thermal and mechanical properties.

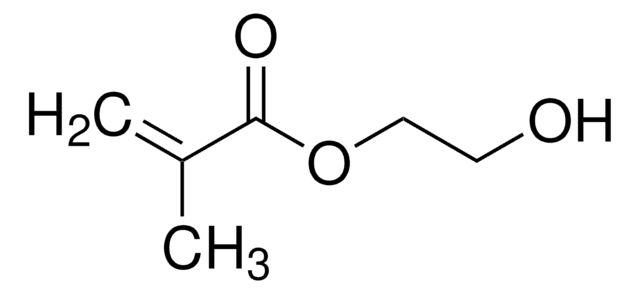

- Poly(methyl methacrylate-co-hydroxyethyl methacrylate) (PMMA-co-PHEMA) copolymers by emulsion copolymerization. These copolymers form thermooxidatively stable and ductile films.

- Poly(methyl methacrylate) nanoparticles through differential microemulsion polymerization.

신호어

Danger

유해 및 위험 성명서

Hazard Classifications

Flam. Liq. 2 - Skin Irrit. 2 - Skin Sens. 1B - STOT SE 3

표적 기관

Respiratory system

Storage Class Code

3 - Flammable liquids

WGK

WGK 1

Flash Point (°F)

50.0 °F - closed cup

Flash Point (°C)

10 °C - closed cup

개인 보호 장비

Eyeshields, Faceshields, Gloves, type ABEK (EN14387) respirator filter

이미 열람한 고객

문서

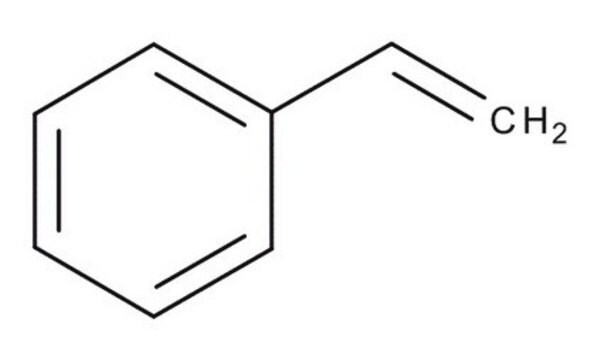

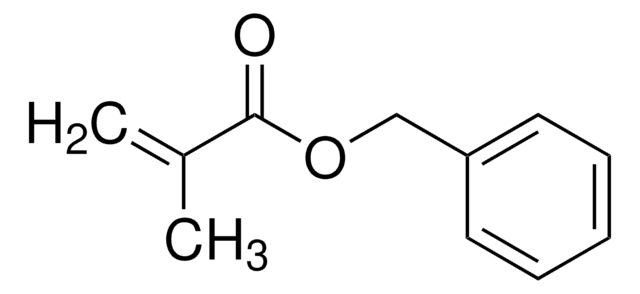

RAFT (Reversible Addition Fragmentation chain Transfer) polymerization is a reversible deactivation radical polymerization (RDRP) and one of the more versatile methods for providing living characteristics to radical polymerization.

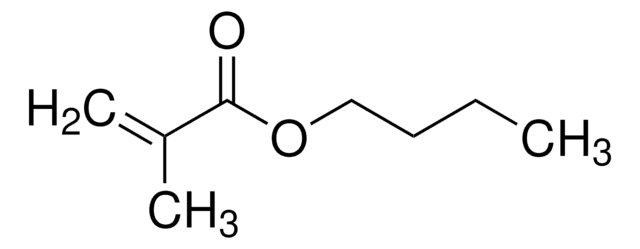

The manufacture of monomers for use in ophthalmic applications is driven by the need for higher purity, improved reliability of manufacturing supply, but ultimately by the need for the increased comfort, convenience, and safety of contact lens wearers. Daily wear contact lenses have the potential to fill this need for many customers; however, their widespread use is constrained by higher costs compared to weekly- or monthly-based lenses. New approaches that improve cost structure and result in higher quality raw materials are needed to help make contact lenses more affordable and accelerate growth of the contact lens market.

프로토콜

We presents an article about ARGET ATRP, and its procedure for PMMA polymer brush growth. Surface preparation before polymer brush growth consists of two steps: surface cleaning and initiator monolayer deposition.

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.