推荐产品

描述

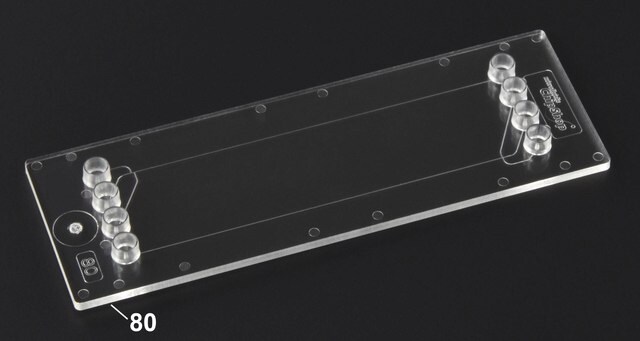

Microfludic chip x1

正在寻找类似产品? 访问 产品对比指南

應用

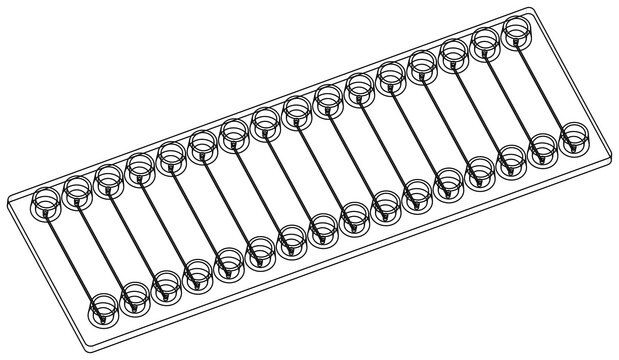

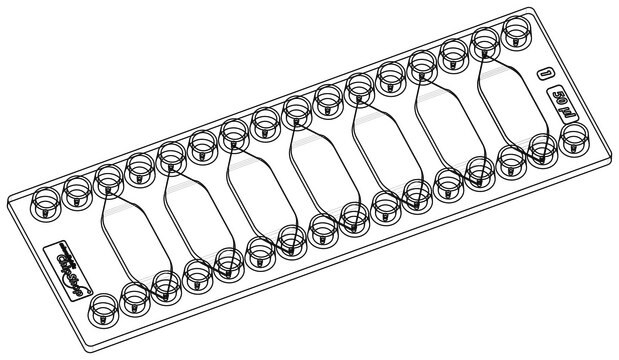

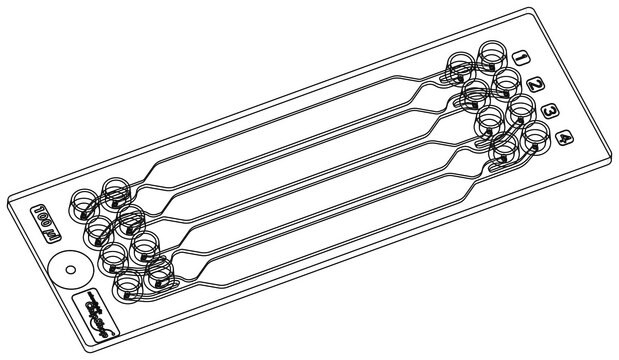

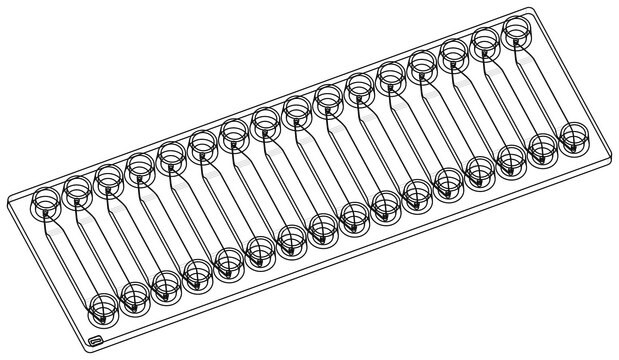

The Pillar Chip Fluidic 261 COP microfluidic chip uses integrated pillars to serve various needs.

特點和優勢

The integrated pillar structures can be used to

- Maintain particles at a certain area

- Allow for self-filling of devices via capillary forces

- Increase surface area

- Have a sieving effect

- Functionalize particle surfaces

成分

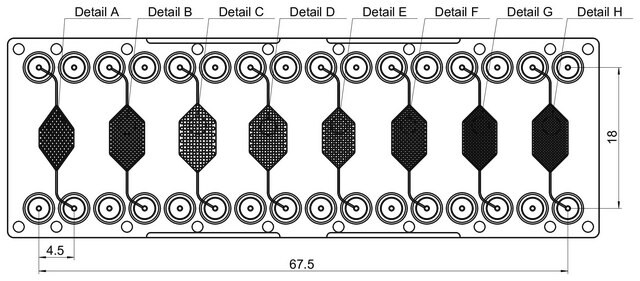

Chip Properties:

2.150 μm/ 400 μm/ 150 μm

3.200 μm/ 500 μm/ 200 μm

4.250 μm/ 500 μm/ 200 μm

5.300 μm/ 700 μm/ 250 μm

6.350 μm/ 800 μm/ 250 μm

7.150 μm/ 500 μm/ 300 μm

8.150 μm/ 500-700 μm/ 300μm

- Mini Luer Interface

- Material: Cyclic olefin polymer (COP)

- Pillars have a demolding angle of 10°

- Pillar Number: Diameter/Distance/Depth

2.150 μm/ 400 μm/ 150 μm

3.200 μm/ 500 μm/ 200 μm

4.250 μm/ 500 μm/ 200 μm

5.300 μm/ 700 μm/ 250 μm

6.350 μm/ 800 μm/ 250 μm

7.150 μm/ 500 μm/ 300 μm

8.150 μm/ 500-700 μm/ 300μm

Sharma T Sanjay et al.

Advanced drug delivery reviews, 128, 3-28 (2017-09-19)

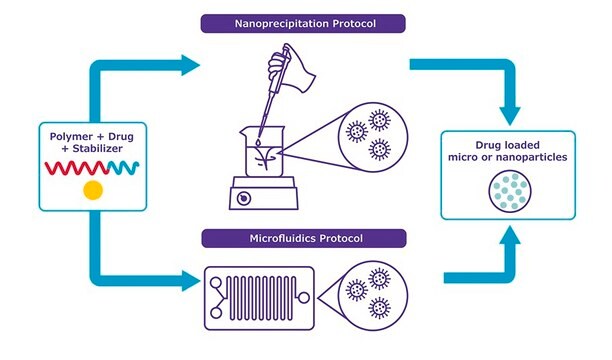

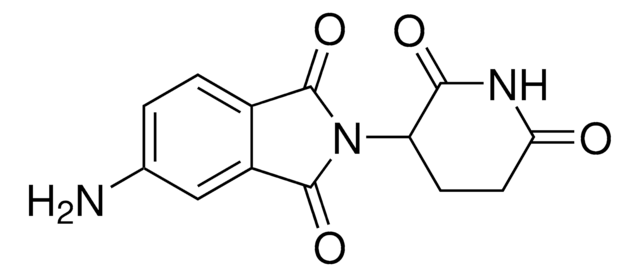

Conventional systematically-administered drugs distribute evenly throughout the body, get degraded and excreted rapidly while crossing many biological barriers, leaving minimum amounts of the drugs at pathological sites. Controlled drug delivery aims to deliver drugs to the target sites at desired

Dongfei Liu et al.

Lab on a chip, 17(11), 1856-1883 (2017-05-10)

The microfluidic technique has brought unique opportunities toward the full control over the production processes for drug delivery carriers, owing to the miniaturisation of the fluidic environment. In comparison to the conventional batch methods, the microfluidic setup provides a range

Global Trade Item Number

| 货号 | GTIN |

|---|---|

| 926426-1EA | 4065267905396 |

我们的科学家团队拥有各种研究领域经验,包括生命科学、材料科学、化学合成、色谱、分析及许多其他领域.

联系客户支持