128635

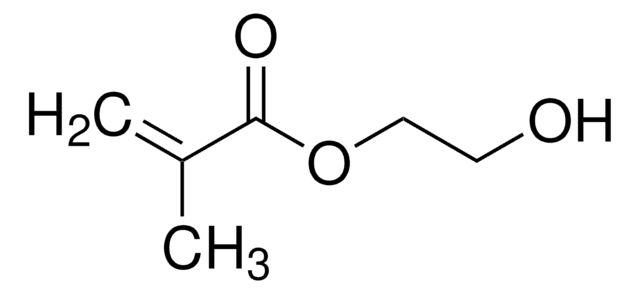

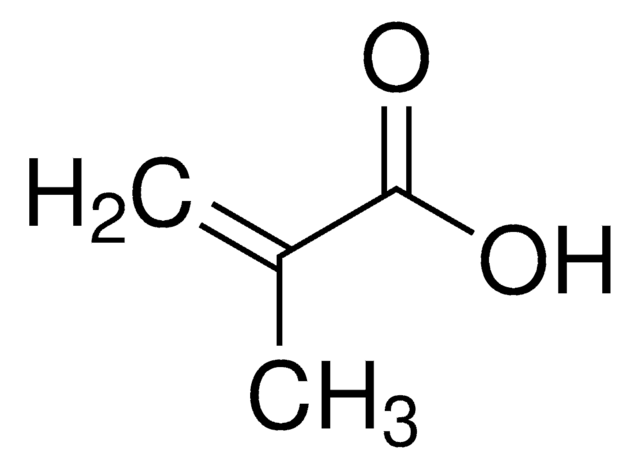

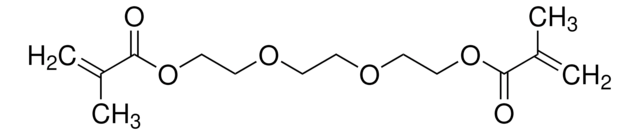

2-Hydroxyethyl methacrylate

contains ≤250 ppm monomethyl ether hydroquinone as inhibitor, 97%

Synonyme(s) :

1,2-Ethanediol mono(2-methylpropenoate), Glycol methacrylate, HEMA

About This Item

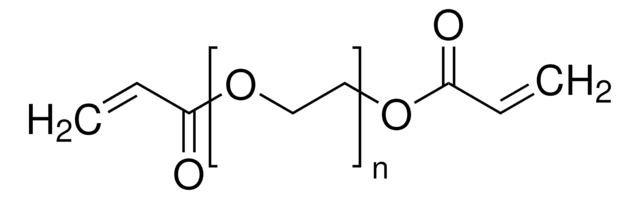

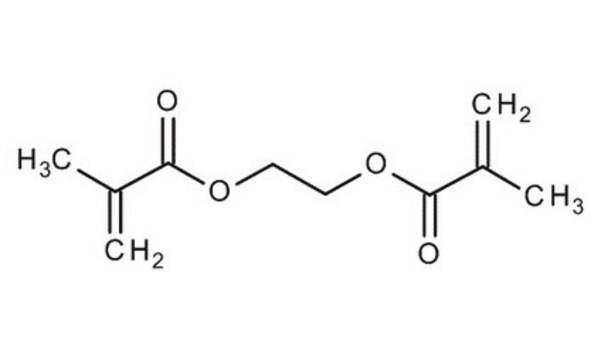

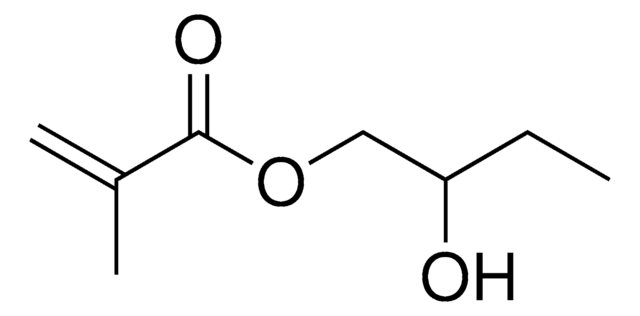

Produits recommandés

Densité de vapeur

5 (vs air)

Pression de vapeur

0.01 mmHg ( 25 °C)

Pureté

97%

Forme

liquid

Contient

≤250 ppm monomethyl ether hydroquinone as inhibitor

Indice de réfraction

n20/D 1.453 (lit.)

Point d'ébullition

67 °C/3.5 mmHg (lit.)

Densité

1.073 g/mL at 25 °C (lit.)

Température de stockage

2-8°C

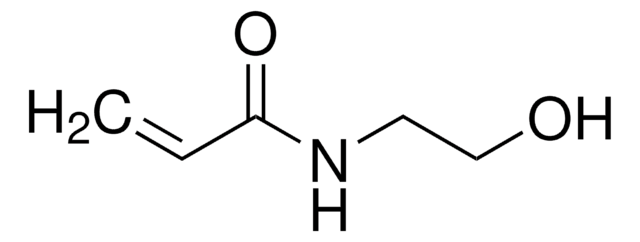

Chaîne SMILES

CC(=C)C(=O)OCCO

InChI

1S/C6H10O3/c1-5(2)6(8)9-4-3-7/h7H,1,3-4H2,2H3

Clé InChI

WOBHKFSMXKNTIM-UHFFFAOYSA-N

Vous recherchez des produits similaires ? Visite Guide de comparaison des produits

Catégories apparentées

Description générale

Application

Mention d'avertissement

Warning

Mentions de danger

Conseils de prudence

Classification des risques

Eye Irrit. 2 - Skin Irrit. 2 - Skin Sens. 1

Code de la classe de stockage

10 - Combustible liquids

Classe de danger pour l'eau (WGK)

WGK 1

Point d'éclair (°F)

222.8 °F - closed cup

Point d'éclair (°C)

106 °C - closed cup

Faites votre choix parmi les versions les plus récentes :

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

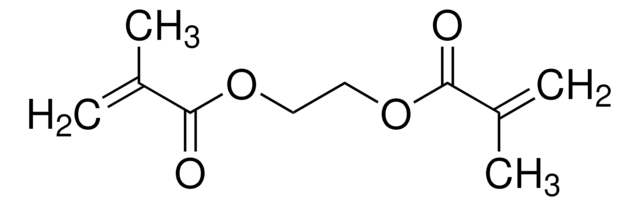

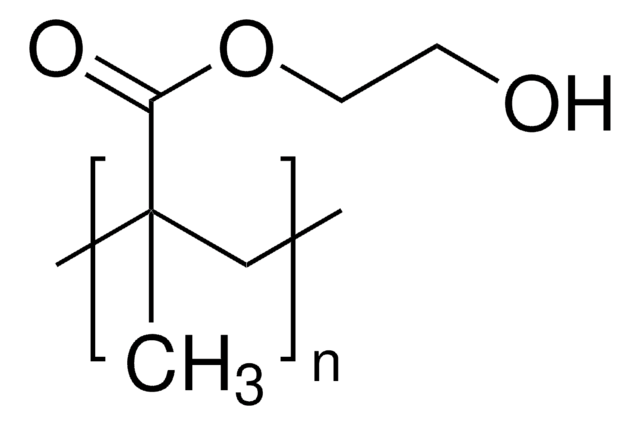

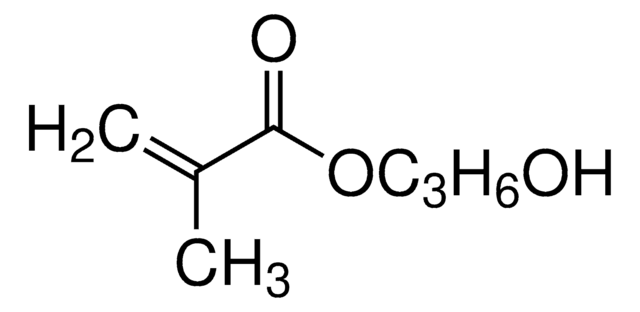

Les clients ont également consulté

Articles

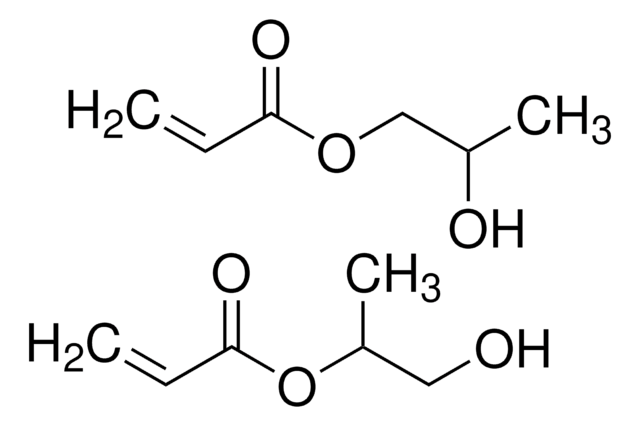

The manufacture of monomers for use in ophthalmic applications is driven by the need for higher purity, improved reliability of manufacturing supply, but ultimately by the need for the increased comfort, convenience, and safety of contact lens wearers. Daily wear contact lenses have the potential to fill this need for many customers; however, their widespread use is constrained by higher costs compared to weekly- or monthly-based lenses. New approaches that improve cost structure and result in higher quality raw materials are needed to help make contact lenses more affordable and accelerate growth of the contact lens market.

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique