560596

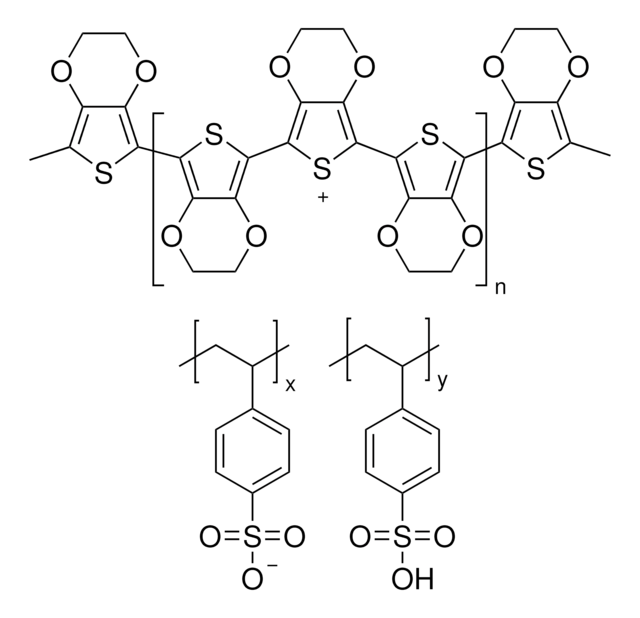

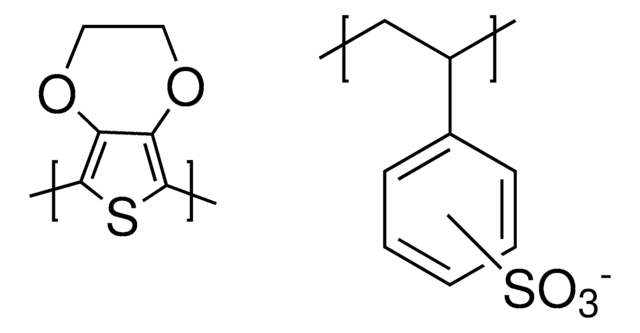

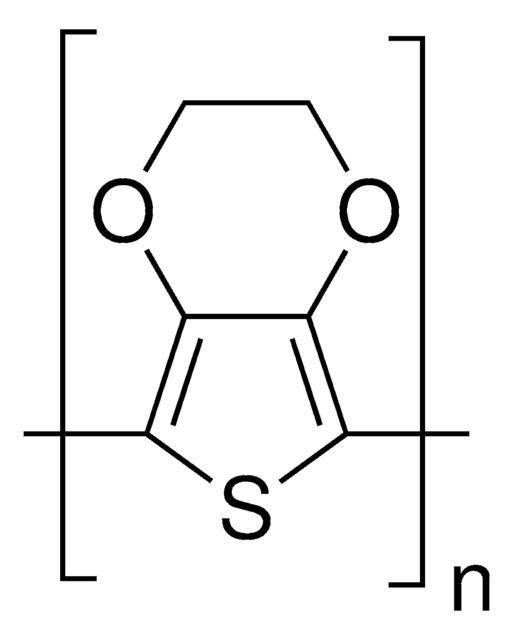

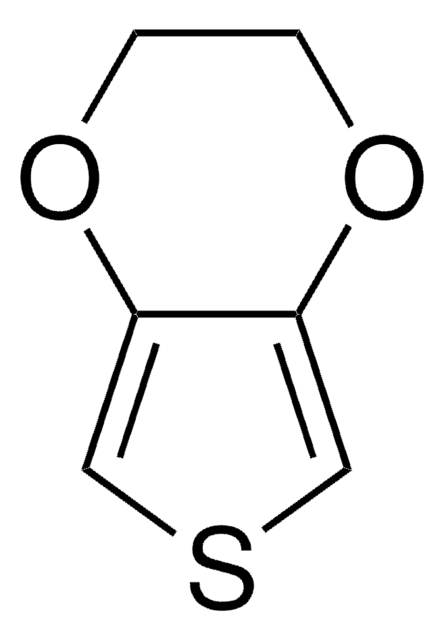

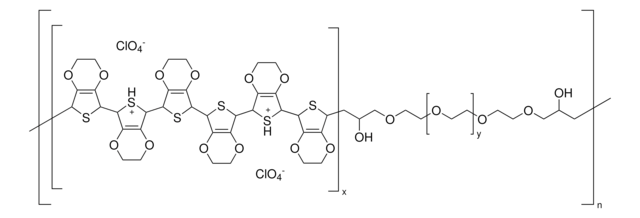

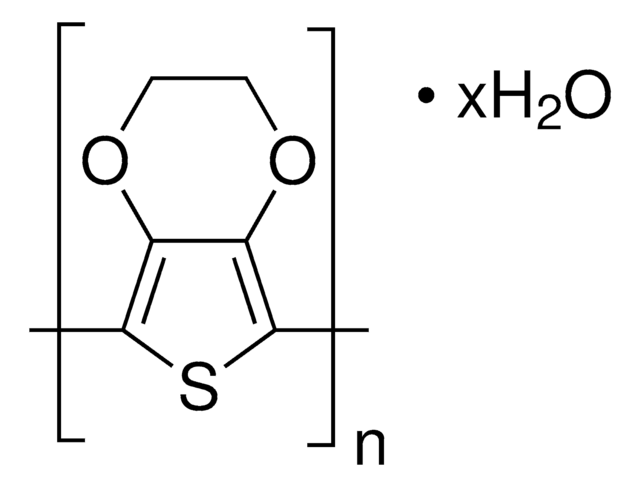

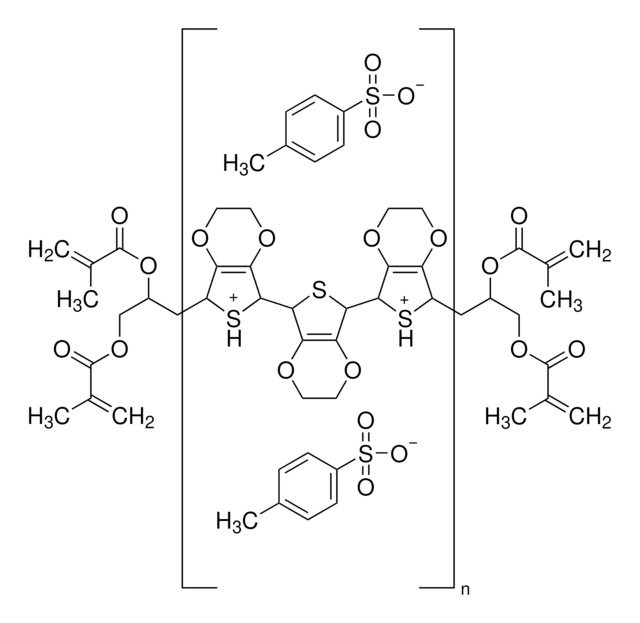

PEDOT:PSS

low-conductivity grade, 2.7 wt. % aqueous dispersion

Sinónimos:

PEDOT:PSS, Poly(2,3-dihydrothieno-1,4-dioxin)-poly(styrenesulfonate)

About This Item

Productos recomendados

Nombre del producto

Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate), 2.7 wt % dispersion in H2O

composición

PEDOT content, ~0.14%

PSS content, ~2.6%

Nivel de calidad

concentración

2.7 wt % dispersion in H2O

impurezas

<300 ppm Na

tamaño de partícula

<200 nm, coeff var >95%

pH

1.2-1.8

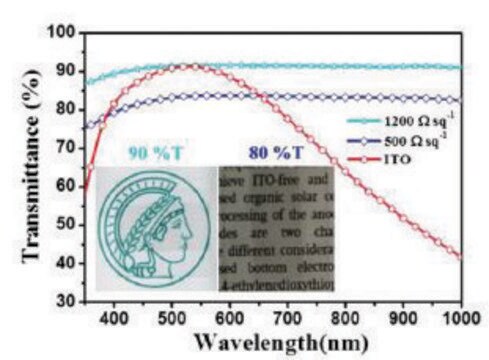

conductividad

~1E-5 S/cm

viscosidad

<20 cP(20 °C)

temp. de almacenamiento

2-8°C

¿Está buscando productos similares? Visita Guía de comparación de productos

Categorías relacionadas

Descripción general

Aplicación

Características y beneficios

Envase

Palabra de señalización

Danger

Frases de peligro

Consejos de prudencia

Clasificaciones de peligro

Eye Dam. 1 - Skin Corr. 1

Código de clase de almacenamiento

8B - Non-combustible corrosive hazardous materials

Clase de riesgo para el agua (WGK)

WGK 2

Punto de inflamabilidad (°F)

Not applicable

Punto de inflamabilidad (°C)

Not applicable

Equipo de protección personal

Faceshields, Gloves, Goggles, type ABEK (EN14387) respirator filter

Elija entre una de las versiones más recientes:

¿Ya tiene este producto?

Encuentre la documentación para los productos que ha comprado recientemente en la Biblioteca de documentos.

Los clientes también vieron

Artículos

Tutorial Lithography Nanopatterning at Sigma-Aldrich. Lithography, based on traditional ink-printing techniques, is a process for patterning various layers, such as conductors, semiconductors, or dielectrics, on a surface.

New conducting and semiconducting polymers for plastic electronics

Find advantages of inorganic interface layer inks for organic electronic & other applications.

Conducting polymers such as polyaniline, polythiophene and polyfluorenes are now much in the spotlight for their applications in organic electronics and optoelectronics.

Global Trade Item Number

| Número de referencia del producto (SKU) | GTIN |

|---|---|

| 560596-25G | 4061832583433 |

| 560596-100G | 4061832583426 |

Nuestro equipo de científicos tiene experiencia en todas las áreas de investigación: Ciencias de la vida, Ciencia de los materiales, Síntesis química, Cromatografía, Analítica y muchas otras.

Póngase en contacto con el Servicio técnico