793361

Zinc oxide nanoparticle ink

Synonyme(s) :

Avantama N-10, Nanograde N-10, Zinc oxide suspension, ZnO dispersion, ZnO ink, ZnO nanoparticle ink

About This Item

Produits recommandés

Forme

dispersion

Niveau de qualité

Concentration

2.5 wt. % (crystalline ZnO in 2-propanol)

Couleur

translucent yellowish

Taille des particules

10-15 nm

Densité

0.800 g/mL at 25 °C

Description générale

Application

Annealing temperature <100°C.

Autres remarques

Post-treatment: Annealing of deposited ZnO films at 80°C - 120°C

Informations légales

Mention d'avertissement

Danger

Mentions de danger

Conseils de prudence

Classification des risques

Aquatic Chronic 2 - Eye Irrit. 2 - Flam. Liq. 2 - STOT SE 3

Organes cibles

Central nervous system

Code de la classe de stockage

3 - Flammable liquids

Classe de danger pour l'eau (WGK)

WGK 1

Point d'éclair (°F)

53.6 °F

Point d'éclair (°C)

12 °C

Faites votre choix parmi les versions les plus récentes :

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

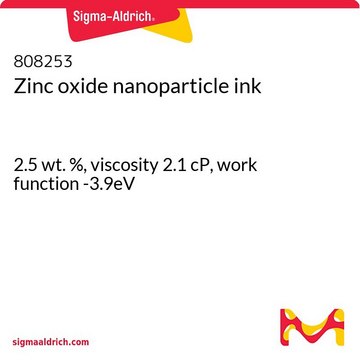

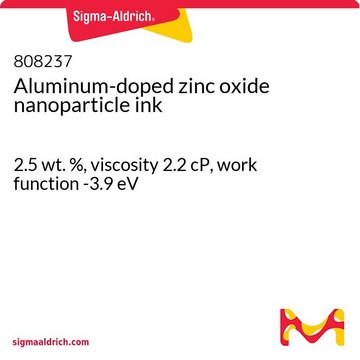

Les clients ont également consulté

Articles

Find advantages of inorganic interface layer inks for organic electronic & other applications.

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Recent progress in the area of solution-processed functional materials has led to the development of a variety of thin-film optoelectronic devices with significant promise in the industrial and consumer electronics fields.

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique