761028

SYLGARD® 184

5 g clip-pack

Synonym(e):

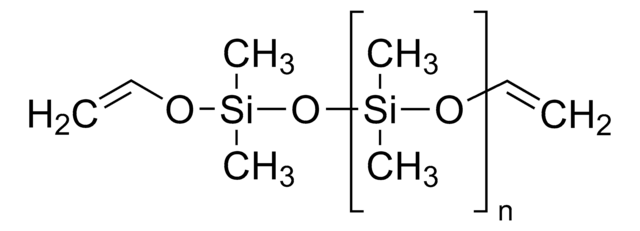

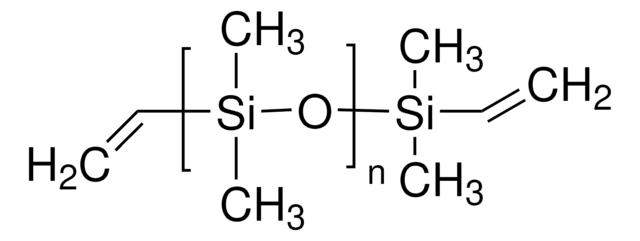

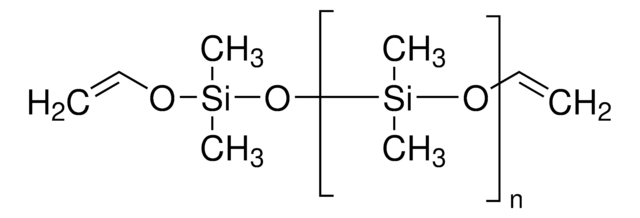

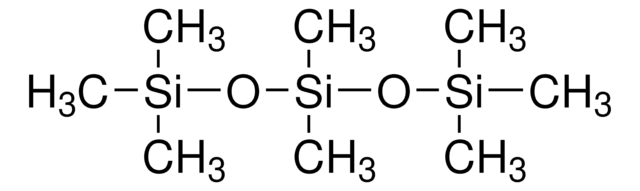

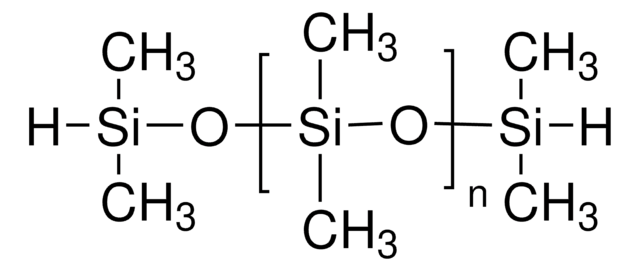

Aushärtungsmittel, Polydimethylsiloxan, Silikon, Vinyl-terminiertes PDMS

Anmeldenzur Ansicht organisationsspezifischer und vertraglich vereinbarter Preise

Alle Fotos(1)

About This Item

UNSPSC-Code:

12162002

NACRES:

NA.23

Empfohlene Produkte

Qualitätsniveau

Form

liquid

Suchen Sie nach ähnlichen Produkten? Aufrufen Leitfaden zum Produktvergleich

Verwandte Kategorien

Allgemeine Beschreibung

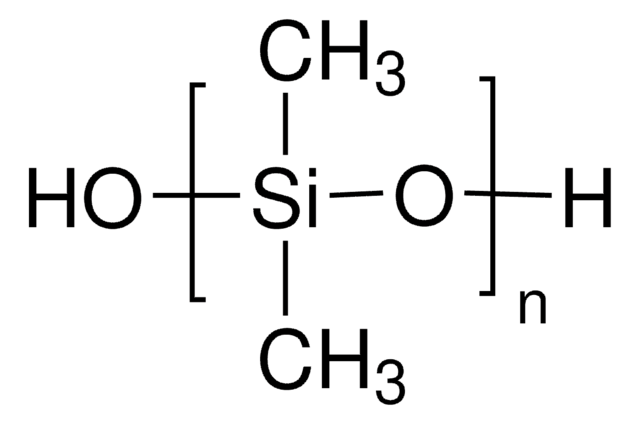

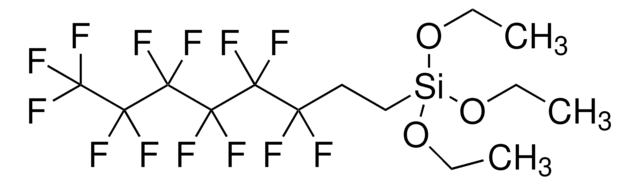

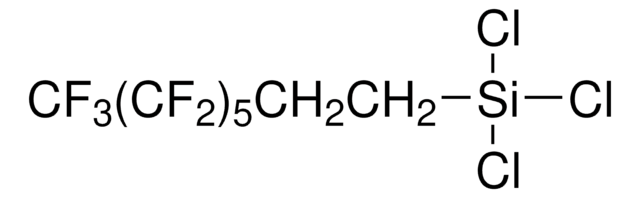

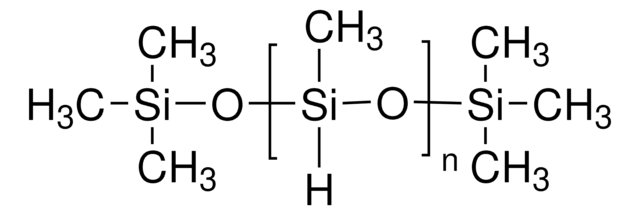

SYLGARD® 184 ist ein Elastomer-Kit auf Silikonbasis. Dieses Zweikomponentensystem besteht aus einem Polymer und einem Härter, der sich mit der Polymermatrix vernetzt. Das dadurch entstehende Komposit ist ein Polydimethylsiloxan (PDMS) mit einer Zugfestigkeit (UTS) von ~ 5,2 MPa und einer Shore-Härte von ~ 44 bei Raumtemperatur. UTS, Härte und Elastizitätsmodul (E) erhöhen sich bei höherer Härtungstemperatur.

Anwendung

PDMS auf SYLGARD® 184-Basis kann in der weichen Lithografie für eine Vielzahl von Anwendungen wie Mikrofluidik, mikroelektromechanische Systeme (MEMS) und andere flexible Elektronikgeräte verwendet werden. Es wird auch in hydrophoben PDMS-Beschichtungen verwendet, die als Feuchtigkeitsmembranen in Photovoltaikzellen eingesetzt werden können.

Verpackung

Monomer und Härter, fertig abgewogen, in praktischen Blistern. Diese zwei Bestandteile werden in einem durchsichtigen Beutel mit separaten Kammern (nicht vorgemischt) verpackt.

Das SYLGARD 184 Silikonelastomer-Kit beinhaltet Base und Härter, die in einem Gewichtsverhältnis von 10 (Base) :1 (Härter) manuell gemischt werden müssen.

Das SYLGARD 184 Silikonelastomer-Kit beinhaltet Base und Härter, die in einem Gewichtsverhältnis von 10 (Base) :1 (Härter) manuell gemischt werden müssen.

Angaben zur Herstellung

PREPARING SURFACES - In applications requiring adhesion, priming will be required for many of the silicone encapsulants. For best results, the primer should be applied in a very thin, uniform coating and then wiped off after application. After application, it should be thoroughly cured prior to application of the silicone elastomer. Additional instructions for primer usage can be found in the information sheets specific to the individual primers.

PROCESSING/CURING - Thoroughly mixed the silicone encapsulant may be poured/dispensed directly into the container in which it is to be cured. Care should be taken to minimize air entrapment. When practical, pouring/dispensing should be done under vacuum, particularly if the component being potted or encapsulated has many small voids. If this technique cannot be used, the unit should be evacuated after the silicone encapsulant has been poured/ dispensed. Dow silicone encapsulants may be either room temperature (25 °C /77°F) or heat cured. Room temperature cure encapsulants may also be heat accelerated for faster cure. Ideal cure conditions for each product are given in the product selection table.

POT LIFE AND CURE RATE - Cure reaction begins with the mixing process. Initially, cure is evidenced by a gradual increase in viscosity, followed by gelation and conversion to a solid elastomer. Pot life is defined as the time required for viscosity to double after base and curing agent are mixed and is highly temperature and application dependent. Please refer to the data table.

USEFUL TEMPERATURE RANGES - For most uses, silicone elastomers should be operational over a temperature range of -45 to 200°C (-49 to 392°F) for long periods of time. However, at both the low and high temperature ends of the spectrum, behavior of the materials and performance in particular applications can become more complex and require additional considerations and should be adequately tested for the particular end-use environment. For low temperature performance, thermal cycling to conditions such as -55°C (-67°F) may be possible, but performance should be verified for your parts or assemblies. Factors that may influence performance are configuration and stress sensitivity of components, cooling rates and hold times, and prior temperature history. At the high-temperature end, the durability of the cured silicone elastomer is time and temperature dependent. As expected, the higher the temperature, the shorter the time the material will remain useable.

COMPATIBILITY - Certain materials, chemicals, curing agents and plasticizers can inhibit the cure of addition cure gels. Most notable of these include: Organotin and other organometallic compounds, silicone rubber containing organotin catalyst, sulfur, polysulfides, polysulfones or other sulfur containing materials, unsaturated hydrocarbon plasticizers, and some solder flux residues. If a substrate or material is questionable with respect to potentially causing inhibition of cure, it is recommended that a small scale compatibility test be run to ascertain suitability in a given application. The presence of liquid or uncured product at the interface between the questionable substrate and the cured gel indicates incompatibility and inhibition of cure.

PROCESSING/CURING - Thoroughly mixed the silicone encapsulant may be poured/dispensed directly into the container in which it is to be cured. Care should be taken to minimize air entrapment. When practical, pouring/dispensing should be done under vacuum, particularly if the component being potted or encapsulated has many small voids. If this technique cannot be used, the unit should be evacuated after the silicone encapsulant has been poured/ dispensed. Dow silicone encapsulants may be either room temperature (25 °C /77°F) or heat cured. Room temperature cure encapsulants may also be heat accelerated for faster cure. Ideal cure conditions for each product are given in the product selection table.

POT LIFE AND CURE RATE - Cure reaction begins with the mixing process. Initially, cure is evidenced by a gradual increase in viscosity, followed by gelation and conversion to a solid elastomer. Pot life is defined as the time required for viscosity to double after base and curing agent are mixed and is highly temperature and application dependent. Please refer to the data table.

USEFUL TEMPERATURE RANGES - For most uses, silicone elastomers should be operational over a temperature range of -45 to 200°C (-49 to 392°F) for long periods of time. However, at both the low and high temperature ends of the spectrum, behavior of the materials and performance in particular applications can become more complex and require additional considerations and should be adequately tested for the particular end-use environment. For low temperature performance, thermal cycling to conditions such as -55°C (-67°F) may be possible, but performance should be verified for your parts or assemblies. Factors that may influence performance are configuration and stress sensitivity of components, cooling rates and hold times, and prior temperature history. At the high-temperature end, the durability of the cured silicone elastomer is time and temperature dependent. As expected, the higher the temperature, the shorter the time the material will remain useable.

COMPATIBILITY - Certain materials, chemicals, curing agents and plasticizers can inhibit the cure of addition cure gels. Most notable of these include: Organotin and other organometallic compounds, silicone rubber containing organotin catalyst, sulfur, polysulfides, polysulfones or other sulfur containing materials, unsaturated hydrocarbon plasticizers, and some solder flux residues. If a substrate or material is questionable with respect to potentially causing inhibition of cure, it is recommended that a small scale compatibility test be run to ascertain suitability in a given application. The presence of liquid or uncured product at the interface between the questionable substrate and the cured gel indicates incompatibility and inhibition of cure.

Rechtliche Hinweise

Sylgard is a registered trademark of The Dow Chemical Company or an affiliated company of Dow

Signalwort

Warning

H-Sätze

Gefahreneinstufungen

Eye Irrit. 2 - Skin Irrit. 2 - STOT SE 3

Zielorgane

Respiratory system

Lagerklassenschlüssel

10 - Combustible liquids

Flammpunkt (°F)

250.0 °F

Flammpunkt (°C)

121.11 °C

Hier finden Sie alle aktuellen Versionen:

Besitzen Sie dieses Produkt bereits?

In der Dokumentenbibliothek finden Sie die Dokumentation zu den Produkten, die Sie kürzlich erworben haben.

Kunden haben sich ebenfalls angesehen

Process and material properties of polydimethylsiloxane (PDMS) for Optical MEMS

Schneider F, et al.

Sensors and actuators A, Physical, 151(2), 95-99 (2009)

Mechanical characterization of bulk Sylgard 184 for microfluidics and microengineering

Johnston ID, et al.

Journal of Micromechanics and Microengineering, 24(3), 035017-035017 (2014)

Odom, Teri W.; et al.

Langmuir, 18, 5314-5320 (2002)

Suh, Kahp Y.; et al.

Advanced Materials, 13, 1386-1389 (2001)

Soft lithography for micro-and nanoscale patterning

Qin D, et al.

Nature Protocols, 5(3), 491-491 (2010)

Unser Team von Wissenschaftlern verfügt über Erfahrung in allen Forschungsbereichen einschließlich Life Science, Materialwissenschaften, chemischer Synthese, Chromatographie, Analytik und vielen mehr..

Setzen Sie sich mit dem technischen Dienst in Verbindung.