901970

SunTronic® conductive graphite ink for flexographic printing

Sinônimo(s):

Conductive ink, Graphite/carbon ink, SunTronic® GFT4600 flexo conductive graphite ink

About This Item

Produtos recomendados

descrição

Sheet resistance: <100 Ω/sq (flexo printed on SBS board with 18 BCM anilox roll)

Specific gravity: 1.09g/cm3

Formulário

liquid

viscosidade

1300-1700 cP (Brookfield - low shear)

temperatura de armazenamento

2-8°C

Descrição geral

GFT4600 is appropriate for paper and cardboard substrates and also water-receptive polymer films and provides a unique combination of high-speed printability, fast drying, and conductivity in an easy-to-use ink system. GFT4600 can also be printed on plastic films bearing a water-receptive primer

Atenção

GFT4600 is a fast drying ink that will dry to the touch between 150-300 feet per minute using standard dryers found on flexographic presses. Maximum conductivity can be achieved with further drying, inline or offline, using infrared (IR) dryers, high capacity forced hot air ovens and/or heated mandrels. Optimum drying conditions should be established for particular equipment used by the customer.

GFT4600 is supplied as ready-for-use ink. Soft sediment may occur over time so thorough mixing prior to use is necessary. The ink may be diluted with water up to 3%, however sheet resistivity will increase slightly. Dilute with caution!

The below details are only a guide, and the final choice of flexo printing specifications may depend on substrate and web speed. To achieve maximum coverage, high volume anilox rolls are recommended (80-120 lpi with 14-22 BCM).

Continuous anilox rotation is required throughout the print run to avoid ink drying on flexo plate and anilox roll. GFT4600 should not be allowed to dry completely on printing equipment. Prompt cleaning with water is highly recommended. Anilox rolls should be also cleaned using a sonicating bath after each print run.

Informações legais

Código de classe de armazenamento

10 - Combustible liquids

Classe de risco de água (WGK)

nwg

Ponto de fulgor (°F)

Not applicable

Ponto de fulgor (°C)

Not applicable

Escolha uma das versões mais recentes:

Certificados de análise (COA)

Não está vendo a versão correta?

Se precisar de uma versão específica, você pode procurar um certificado específico pelo número do lote ou da remessa.

Já possui este produto?

Encontre a documentação dos produtos que você adquiriu recentemente na biblioteca de documentos.

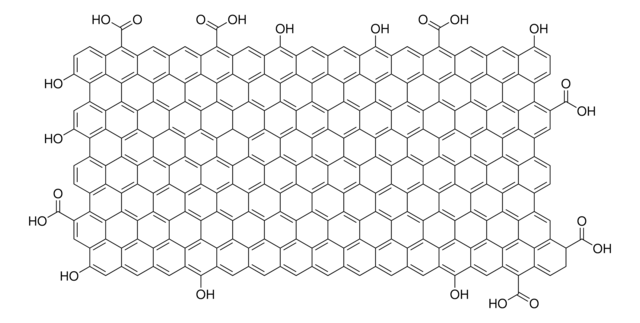

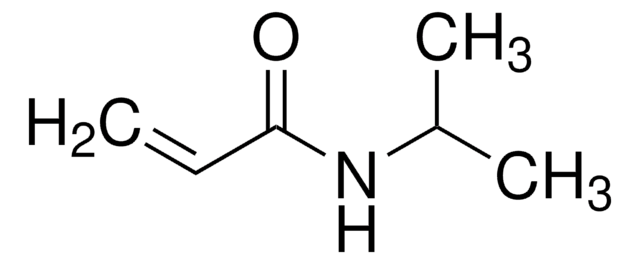

Os clientes também visualizaram

Artigos

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Nossa equipe de cientistas tem experiência em todas as áreas de pesquisa, incluindo Life Sciences, ciência de materiais, síntese química, cromatografia, química analítica e muitas outras.

Entre em contato com a assistência técnica