TZHVSL210

Steritest® NEO Device

This green base canister with a single needle is ideal for testing solvents, creams, ointments, and veterinary injectables.

Synonym(s):

Green Base Steritest® NEO device for sterility testing, Sterility testing device, membrane filtration device, membrane filtration canister, closed membrane filtration

About This Item

Recommended Products

material

Nylon (for canister)

Nylon 66 adapter (for needle)

PVC tubing (double lumen)

PVDF membrane

plain filter

stainless steel (for needle)

Quality Level

Agency

EP (2.6.1)

JP (4.06)

USP 71

sterility

sterile; γ-irradiated

manufacturer/tradename

Steritest®

packaging

pkg of 10 blisters per box, Single packed

parameter

120 mL sample volume (graduation marks at 25, 50, 75 and 100 mL)

3.1 bar max. inlet pressure (45 psi) at 25 °C

45 °C max. temp.

tubing L

850 mm

color

green Canister Base

matrix

Durapore®

pore size

0.45 μm pore size

input

solvent(s)

sample type pharmaceutical(s)

application(s)

pharmaceutical

sterility testing

shipped in

ambient

General description

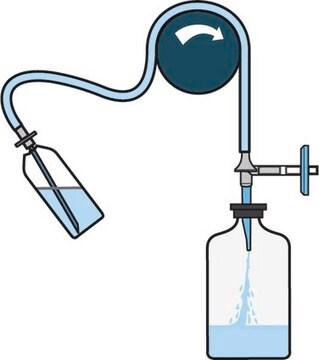

Steritest® NEO Device is a membrane filtration device for sterility testing of filterable pharmaceutical products. The device simplifies every aspect of testing, from handling to traceability. The closed system minimizes false positives and offers the highest levels of quality and reliability, ensuring that pharmaceutical products are never exposed to the environment during the testing process. This test system offers an optimized and fully regulatory compliant testing process, when used with the Steritest® Symbio pump, specific accessories and high-quality culture media and rinsing fluids. The canister connections and reinforced base structure provide better resistance to pressure. The single needle adapter is used for products in vials or ampoules. A separate vent needle is included for the transfer of the test product, culture media or rinsing buffer. The canisters come with green canister base indicating increased chemical compatibility with solvents due to Durapore® Poly vinylidene fluoride (PVDF) membrane and specific canister polymer (nylon). This optimizes the chemical compatibility of products dissolved in solvents.

Application

Features and Benefits

- One-stop-shop for sterility testing with our devices, pumps, media, fluids, and services

- Steritest® devices are manufactured in our Center of Excellence in Molsheim, France, with high-quality control standards maintaining the Certificate of Quality for each lot.

- New needle design

- Smarter workflow

- The new Steritest® NEO cartridge device benefits from all the improvements such as colored clamps, graduations for accurate volume measurement, optimized identification, and traceability with the new peel-off label

- Completely closed set up

- Consistent performance

- New tubing disconnection tool

Packaging

Legal Information

configured for

related product

required but not provided

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

The combination of Sterile Isopropyl Myristate (IPM) and the Steritest® NEO device is an effective solution for sterility testing of viscous products like creams and ointments. IPM enhances sample filterability by diluting these products.

Sterility testing is one of the most crucial steps in pharmaceutical product release. Regulatory-compliant membrane filtration sterility testing devices ensure the safety of pharmaceutical products.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service