900960

Graphene dispersion

for spin/spray-coating, photonic annealing

Synonym(s):

Conductive ink, Graphene ink

About This Item

Recommended Products

Product Name

Graphene ink for spin/spray coating photonically annealable, for spin-coating, spray-coating, photonic annealing

Quality Level

form

dispersion (black)

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

concentration

1.8-3.0 wt. % solids

resistivity

0.003-0.005 Ω-cm, sample prepared by spin-coating at 2000 rpm/30 s for 5 coats, followed by thermal annealing at 300 °C in air for 30 minutes

particle size

≤3 μm

viscosity

2-8 mPa.s(25 °C) (1000 s-1)

bp

78 °C (ethanol)

density

0.78-0.88 g/mL at 25 °C

greener alternative category

, Enabling

General description

Application

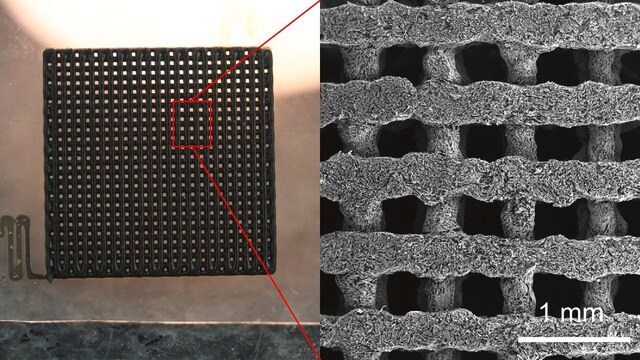

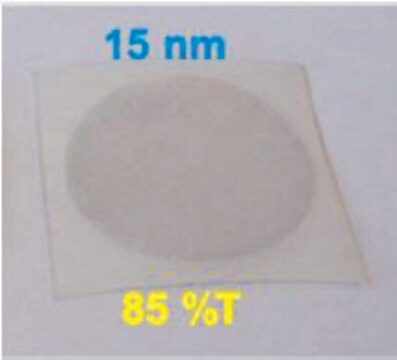

Spin-coating a single layer at 2000-5000 rpm yields a final film thickness of 40-60 nm. To achieve thicker films, multiple layers can be applied without a baking step. This is recommended over using a lower spin speed to maintain film uniformity. This ink should work on almost any substrate.

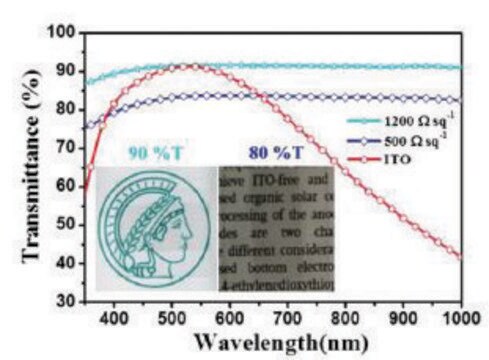

Electrical performance:

Following a baking step at 300 °C for 30 minutes in air, the spin-coated films exhibit sheet resistance of 300-800 Ω/sq, corresponding to a resistivity of 0.003-0.004 Ω−cm. With 5 coats at 2000 rpm, a 200 nm thick film with a sheet resistance of 160 Ω/sq. is obtained.

General guidelines:

Ethanol is recommended for cleaning up the ink and dried films, as well as dilution. Bath sonication (5-10 minutes) of the ink prior to use is recommended following extended periods of disuse.

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Eye Dam. 1 - Flam. Liq. 2 - Skin Irrit. 2

Storage Class Code

3 - Flammable liquids

WGK

WGK 1

Flash Point(F)

54.5 °F - closed cup

Flash Point(C)

12.5 °C - closed cup

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

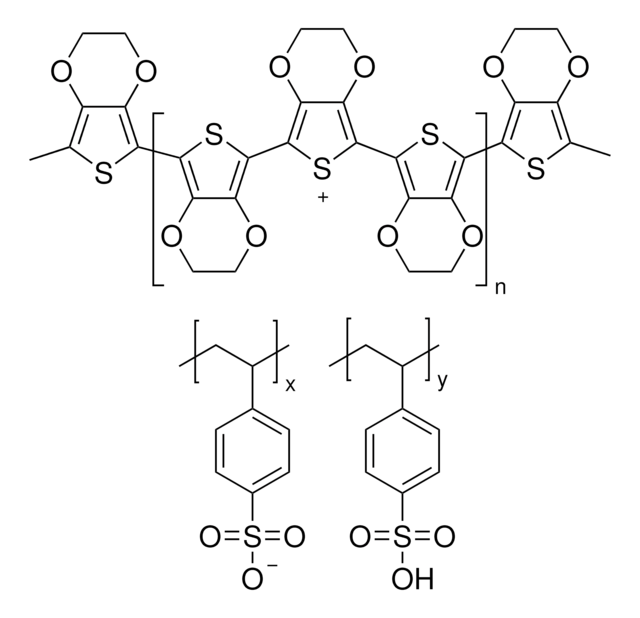

The European Green Deal and Circular Economy Action Plan address resource challenges with eco-products and circulatory work, while the revised EU Ecodesign Directive promotes e-waste reduction and natural resource value reform. This review examines renewable substrates and conductive materials for flexible electronics.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service