939374

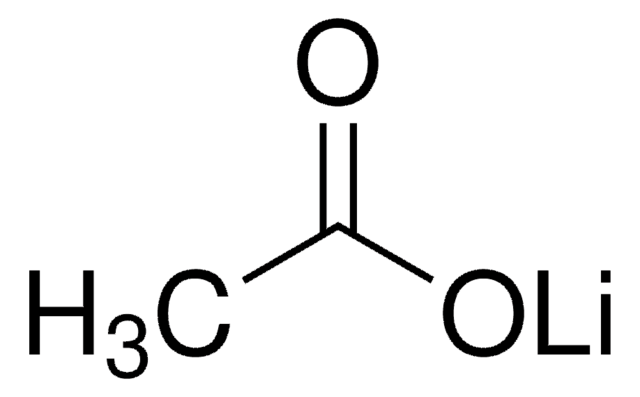

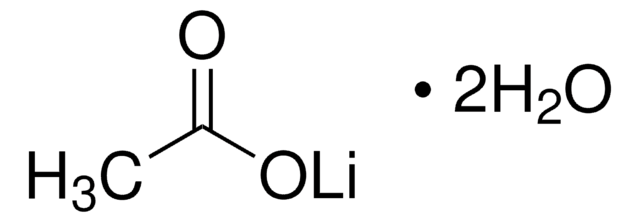

Lithium acetate dihydrate

≥99.9% trace metals basis

Synonym(s):

Acetic acid lithium salt, Acetic acid lithium salt dihydrate

About This Item

Recommended Products

type

(High purity Salts)

Quality Level

Assay

≥99.9% trace metals basis

form

powder or crystals

solid

impurities

≤1000 ppm (trace metals analysis)

color

white to off-white

pH

≤9.5

mp

53-56 °C (lit.)

solubility

water: soluble

anion traces

chloride (Cl-): ≤20 ppm

sulfate (SO42-): ≤50 ppm

cation traces

Al: <100 ppm

Cu: <100 ppm

Fe: <100 ppm

K: <100 ppm

Mg: <100 ppm

Na: ≤50 ppm

Pb: <100 ppm

Zn: <100 ppm

application(s)

battery manufacturing

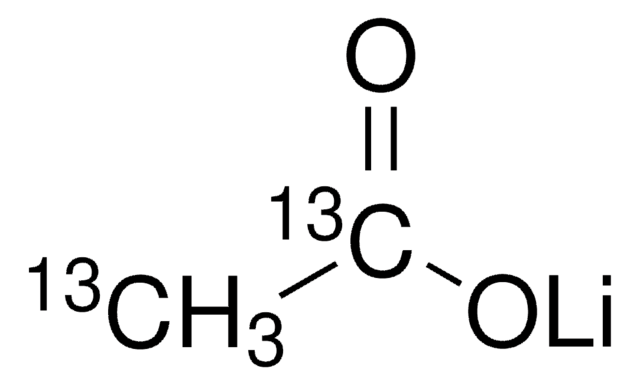

SMILES string

[Li+].[H]O[H].[H]O[H].CC([O-])=O

InChI

1S/C2H4O2.Li.2H2O/c1-2(3)4;;;/h1H3,(H,3,4);;2*1H2/q;+1;;/p-1

InChI key

IAQLJCYTGRMXMA-UHFFFAOYSA-M

Looking for similar products? Visit Product Comparison Guide

General description

Application

Our Lithium acetate dihydrate, with a purity of 99.9% on a trace metals basis, serves as an excellent precursor for batteries and catalysis. Its low trace metals content and anions make it particularly well-suited for these applications.

- Lithium Iron Pyrophosphate (LiFe1.5P2O7) with monoclinic structures was successfully synthesized using Lithium acetate dihydrate in combination with other metal acetates, in a ratio of Li/Fe/P = 1.05:1.5:2, through a wet-chemical method. Maintaining the appropriate lithium concentration is crucial to prevent stoichiometry loss in the final product. This material has found application as a positive electrode in Lithium-ion batteries. Remarkably, the electrode demonstrates excellent incremental capacity, indicating a stable structure during the initial cycle, with redox peaks observed at 3.33 and 3.22 V versus Li0/Li+

- LiMn2O4 films were synthesized on Au foil using the sol-gel and spin-coating techniques, employing Lithium acetate dihydrate and manganese acetate tetrahydrate in a Li/Mn ratio of 1.1/2. The particles used had an average size of approximately 300 nm. To investigate the morphological changes during over-discharging, the EC-HS-AFM technique was utilized. The images captured revealed the presence of wrinkle-like and step-like structures on the particle surface. These structures were attributed to stresses induced by structural distortion during the phase transformation from cubic (LiMn2O4) to tetragonal (Li2Mn2O4). The formation of the Li2Mn2O4 phase was confirmed through ex situ XRD analysis. Furthermore, by analyzing the EC-HS-AFM images, the particle surface area was quantitatively extracted as a function of potential, providing insights into the irreversible expansion/contraction behavior of the particles

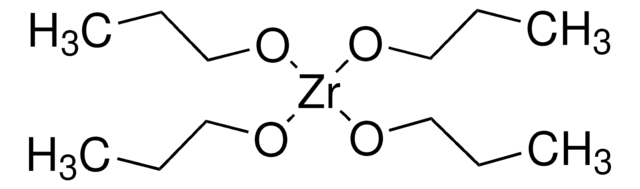

- Cobalt-free cathodes, specifically Mg and Zr modified LiNi0.5Mn1.5O4 (LNMO), were synthesized using Lithium acetate dihydrate and other metal acetates via a citric acid sol-gel method. The modifications aimed to improve the electrochemical performance of the cathode, particularly at high temperatures, by limiting Mn dissolution and adjusting interstitial sites. This modification resulted in increased stability of the cathode, extending the cycle life to 1000 cycles at both 25 and 50 °C

Features and Benefits

- Water soluble

- Medium purity (99.9%)

- Low trace metals in ppm level

- Cost effective

- Low Chloride and sulfate levels

Storage Class Code

11 - Combustible Solids

WGK

WGK 1

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service