793361

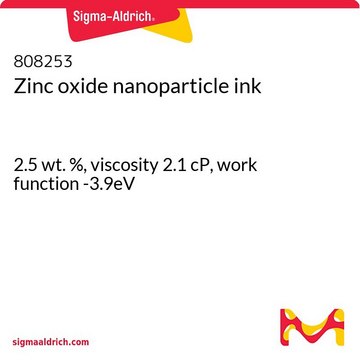

Zinc oxide nanoparticle ink

Synonym(s):

Avantama N-10, Nanograde N-10, Zinc oxide suspension, ZnO dispersion, ZnO ink, ZnO nanoparticle ink

About This Item

Recommended Products

form

dispersion

Quality Level

concentration

2.5 wt. % (crystalline ZnO in 2-propanol)

color

translucent yellowish

particle size

10-15 nm

density

0.800 g/mL at 25 °C

General description

Application

Annealing temperature <100°C.

Other Notes

Post-treatment: Annealing of deposited ZnO films at 80°C - 120°C

Legal Information

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Aquatic Chronic 2 - Eye Irrit. 2 - Flam. Liq. 2 - STOT SE 3

Target Organs

Central nervous system

Storage Class Code

3 - Flammable liquids

WGK

WGK 1

Flash Point(F)

53.6 °F

Flash Point(C)

12 °C

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

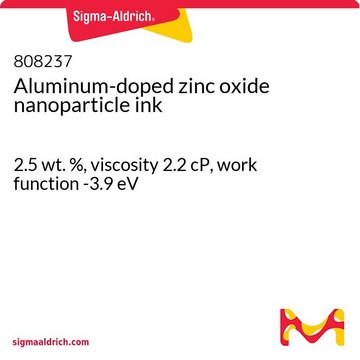

Customers Also Viewed

Articles

Find advantages of inorganic interface layer inks for organic electronic & other applications.

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Recent progress in the area of solution-processed functional materials has led to the development of a variety of thin-film optoelectronic devices with significant promise in the industrial and consumer electronics fields.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service